Radar level transmitters are widely used for continuous liquid measurement under demanding high-temperature operating conditions.

Below is a concise technical overview.

Working Principle

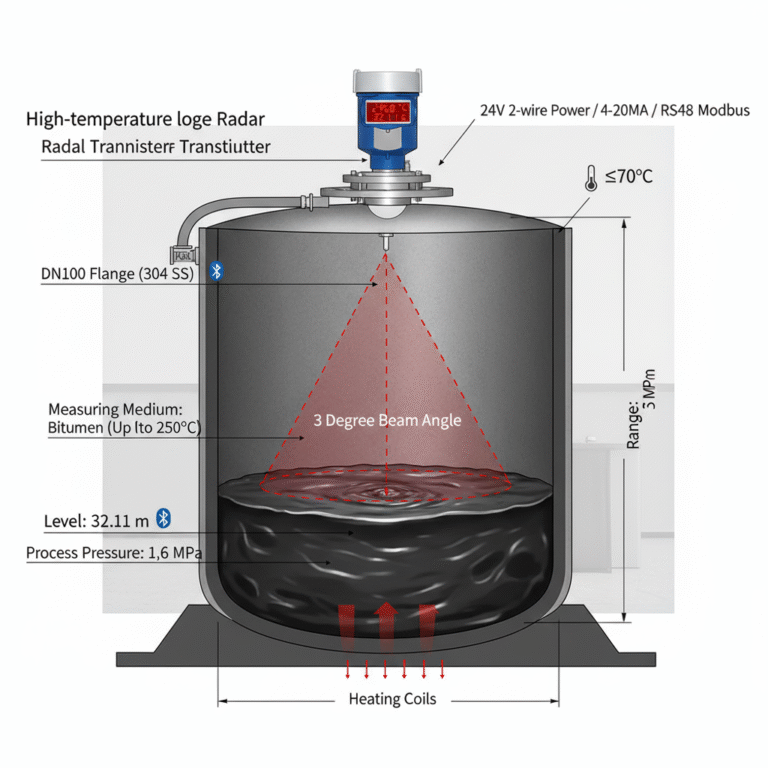

A high-temperature radar level transmitter operates based on high-frequency microwave pulse technology.

The transmitter emits microwave pulses toward the surface of the liquid. These pulses travel at the speed of light, reflect from the liquid surface, and are received by the radar sensor.

By precisely measuring the time of flight between transmission and reception—combined with the known propagation velocity—the instrument calculates the distance to the surface and accurately determines liquid level, regardless of process pressure or temperature.

Key Performance Features

High-temperature radar level transmitters offer:

✔ Non-contact measurement

No physical contact with hot or corrosive media, ensuring high reliability and long service life.

✔ Wide temperature capability

Standard designs: –40°C to 250°C

Enhanced high-temperature models: 300°C–1200°C

This allows use in extremely harsh thermal environments.

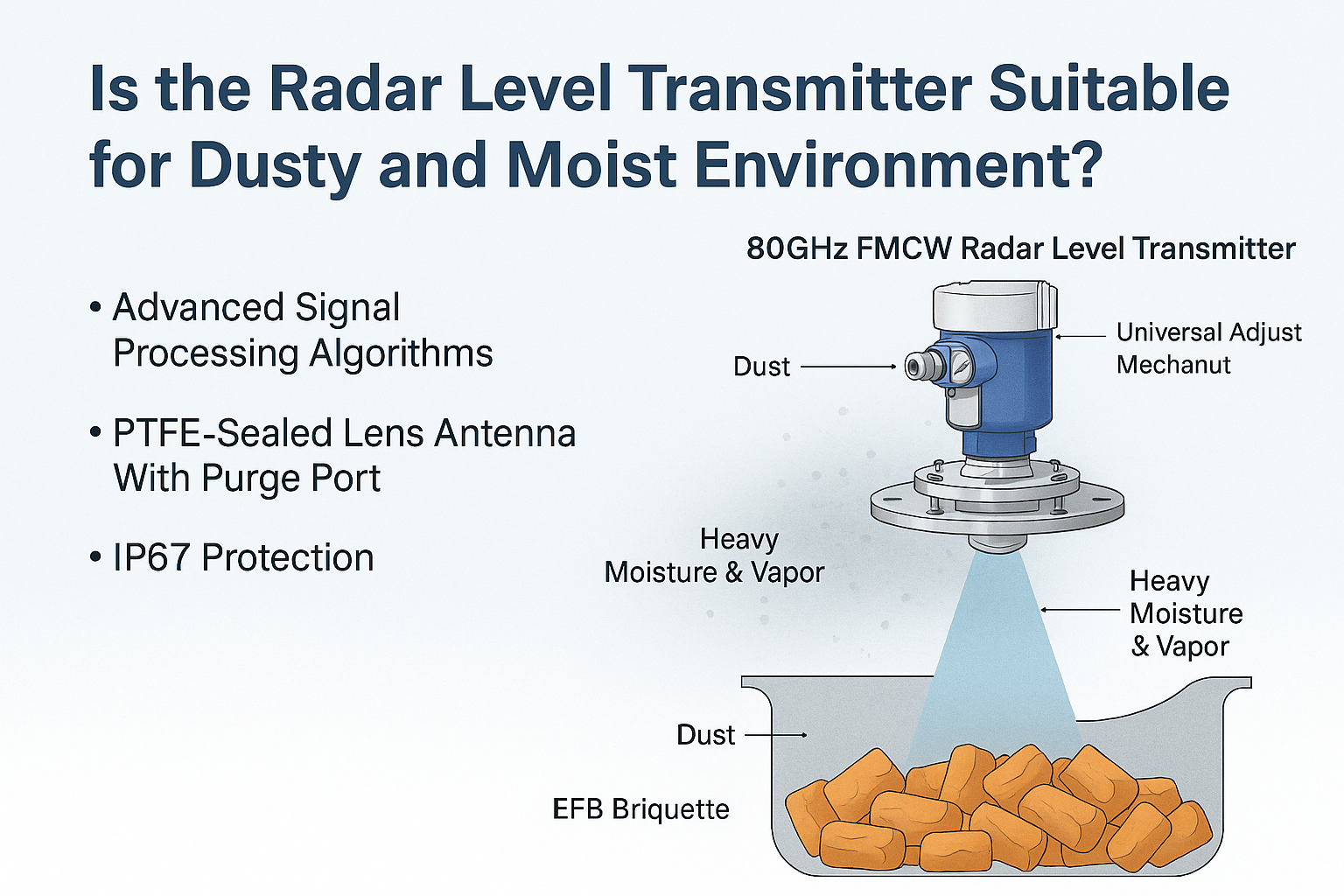

✔ Strong interference resistance

Advanced signal processing enables reliable reading even in the presence of:

Heavy steam

Condensation

Dust

Foaming surfaces

✔ Chemical and mechanical durability

Optional materials such as Hastelloy, PTFE, ceramic lenses, and isolated antenna systems further enhance resistance to corrosive conditions.

Common Types

High-temperature radar sensors are available in several configurations depending on process conditions:

1. Standard High-Temperature Radar

Optimized housing and sealing structure

Suitable for most applications up to ~200°C

2. Ultra-High Temperature Radar

Reinforced thermal isolation and cooling design

Applicable for 350°C and above

Ideal for reactors, thermal oil circuits, molten salt, etc.

3. High-Temperature/High-Pressure Guided Wave Radar

Uses a probe (rod or cable) to guide microwave signals

Excellent performance in vapor, foam or narrow vessels

Example: Shanghai Xingshen RF2030 model, rated up to 520°C

Suitable for high-pressure steam service

Typical Application Industries

High-temperature radar level measurement is widely applied in heavy-duty industrial sectors, including:

Chemical processing – molten salt reactors, polymerization tanks

Metallurgy – blast furnace slag trenches and molten metal feed

Energy and utilities – boiler drum water level monitoring, steam systems

Environmental waste treatment – incinerator ash and molten residue tanks

Radar technology ensures stable level monitoring in environments where mechanical floats or differential pressure devices cannot survive.

Selection Considerations

When choosing a high-temperature radar level transmitter, evaluate the following:

Temperature rating

Select a sensor with at least 20% safety margin beyond maximum process temperature.Medium characteristics

Consider corrosion, vapor content, dielectric constant, and build-up tendencies.Antenna and wetted materials

Options include Hastelloy C, ceramic or PTFE protection depending on chemistry.Process and installation conditions

Pressure class, nozzle size, insertion length, horn vs. lens antenna type.Electronic and communication options

Ensure compatibility with plant control requirements:

4–20 mA / HART / Modbus / Profibus.IP rating & diagnostics

High IP sealing, signal filtering algorithms, and echo curve diagnostics improve reliability in harsh conditions.

✔ Conclusion

High-temperature radar level transmitters provide robust, accurate, and maintenance-free level monitoring across industries where traditional instruments fail. With correct type selection and material configuration, radar offers long-term reliability even in high-temperature, high-pressure, and corrosive environments.