In industrial processes, especially those involving tanks, silos, or reservoirs, level monitoring is critical for ensuring smooth operation and safety. Two key concepts in level monitoring are high-level and low-level indicators. These terms refer to specific points in a container or tank where the level of a material (liquid, solid, or slurry) is monitored. When the material reaches these points, alarms or automated processes are triggered to prevent overfill, underfill, or other operational issues. Below, we explore these concepts in more detail.

1. High-Level Monitoring

Definition: High-level monitoring refers to the detection of a material’s level when it reaches or exceeds a pre-set upper limit within a container or tank. This is critical to avoid overfilling and potential spillage, which could lead to equipment damage, safety hazards, or environmental contamination.

Functionality:

- Alarm Activation: When the material reaches the high-level threshold, the system typically activates an alarm. This could be an audible sound, a visual light, or a signal to the control room.

- Process Control Actions: In some systems, high-level detection triggers automatic actions. For example:

- Stopping the Inlet Flow: If the tank is filling with a liquid, the inlet valve may close automatically to prevent further flow.

- Opening Drain Valves: In some applications, high-level detection could open a drain valve to release material or allow the system to process the excess.

- Activating Backup Systems: In critical systems, high-level alarms might also trigger backup pumps, overflow containment measures, or even shutdown sequences to prevent damage.

Applications:

- Chemical or Water Tanks: In chemical plants or water treatment facilities, high-level monitoring is essential to prevent hazardous spills and ensure that tanks do not overflow. This is particularly important in industries where overflows can lead to severe environmental damage or costly production downtime.

- Oil Storage Tanks: Oil storage tanks require high-level monitoring to avoid spillage and ensure that oil does not exceed safe operational limits.

Common Technologies for High-Level Detection:

- Float Switches: One of the simplest methods, where a buoyant float moves with the material level and triggers a switch when the high-level point is reached.

- Ultrasonic Sensors: These devices emit sound waves that reflect off the surface of the material. When the reflection time changes (as the material level rises), the system can detect the high-level condition.

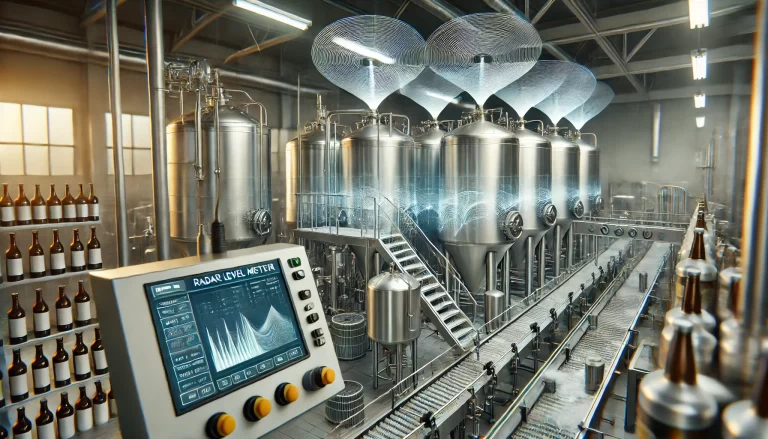

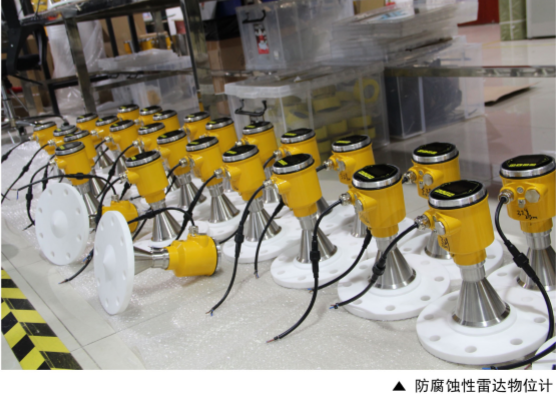

- Radar Sensors: Similar to ultrasonic sensors but using radar waves, these sensors offer high accuracy, particularly for challenging environments such as high temperatures or pressurized systems.

- Capacitive Sensors: These measure changes in capacitance between two plates when the material level changes, which can be used to detect high-level conditions.

2. Low-Level Monitoring

Definition: Low-level monitoring refers to the detection of a material’s level when it drops below a set minimum threshold. This is crucial to avoid operational problems such as dry running of pumps, overheating of heating elements, or running out of essential materials, all of which could damage equipment or disrupt processes.

Functionality:

- Alarm Activation: Low-level sensors typically activate an alarm when the material drops below the threshold. This alarm serves as a warning that the container is nearly empty, signaling the need to replenish the material.

- Control System Responses: In more advanced systems, low-level detection can trigger actions like:

- Stopping Pumps: If the material level in a pump reservoir or storage tank falls too low, the pump may be turned off to prevent it from running dry.

- Starting Refill Systems: In automated systems, low-level alarms can initiate the refilling process, such as activating pumps or opening inlet valves.

- Alerting Operators: Low-level conditions often signal an issue in inventory, supply, or production flow, so operators are alerted to investigate and take corrective action.

Applications:

- Water Supply Systems: Low-level detection is vital in water tanks or reservoirs to ensure that pumps don’t operate without sufficient water, preventing potential damage to the system.

- Food and Beverage Manufacturing: In factories that rely on raw ingredients stored in tanks or silos, low-level monitoring is necessary to prevent production stoppages due to a lack of supply.

- Pharmaceutical and Chemical Production: In these industries, maintaining the proper levels of raw materials is essential for consistent product quality and process stability.

Common Technologies for Low-Level Detection:

- Float Switches: Similar to high-level monitoring, float switches can be set to activate when the material level drops below a certain point.

- Ultrasonic Sensors: These sensors can also be used for low-level detection. By measuring the time it takes for an ultrasonic pulse to travel to the material surface and back, the sensor determines the distance to the material, identifying low levels.

- Pressure Sensors: These are often used in liquid systems to detect the change in pressure that occurs when the material level drops below a certain point, triggering a low-level alarm.

- Radar Sensors: In some applications, radar sensors are used for low-level detection in addition to high-level monitoring, providing high accuracy and reliability in harsh conditions.

3. Significance of High and Low-Level Monitoring

Effective high and low-level monitoring ensures the safe and efficient operation of systems that handle bulk materials. By providing early warnings and automated responses, these monitoring systems help to:

- Prevent Overflows: High-level monitoring prevents spills, which can cause environmental harm or production downtime.

- Protect Equipment: Low-level monitoring protects pumps, heating elements, and other equipment from running dry, which could cause severe damage.

- Increase Efficiency: Automated responses based on high and low-level thresholds allow processes to run smoothly without requiring constant manual oversight.

- Ensure Safety: These monitoring systems are crucial for maintaining the safety of workers and the environment, particularly in industries dealing with hazardous materials.

4. Conclusion

High and low-level monitoring are essential components of modern industrial systems, ensuring smooth, safe, and efficient operations. By automating alerts and responses based on material levels, industries can avoid costly equipment damage, prevent spills, and improve overall process control. Advanced technologies such as float switches, ultrasonic sensors, radar sensors, and pressure sensors provide reliable and accurate monitoring solutions, each suited to specific operational needs and environments.

In any industry where materials are stored or processed in large quantities, understanding and implementing effective high and low-level monitoring can significantly reduce risks and optimize performance.