When discussing safety in factories, it’s common to hear: “We have alarms, interlocks, and safety valves.” However, real safety assessments go beyond simply asking “Do we have these systems?” and address three critical questions:

What could go wrong? (Scenario identification)

Is the risk low enough? (Risk assessment)

If not, how reliable do the protective measures need to be? (Reliability requirements)

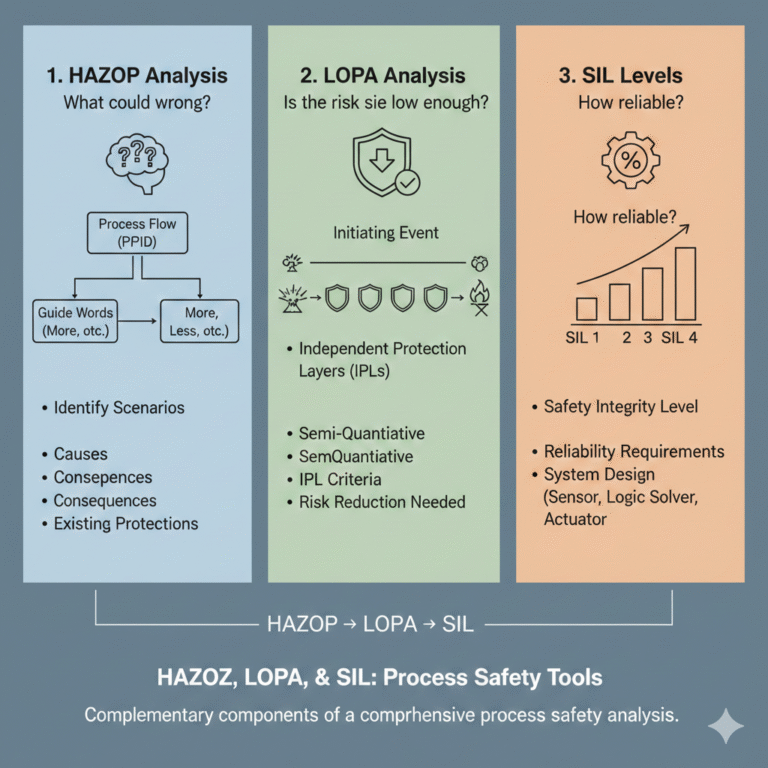

In process safety, three tools are frequently mentioned together and often confused: HAZOP, LOPA, and SIL. By putting them into a logical sequence, we can clarify their roles:

HAZOP: Identifies potential accident scenarios.

LOPA: Evaluates and quantifies the risk of key scenarios.

SIL: Specifies the reliability requirements for protective measures.

1. HAZOP Analysis

HAZOP (Hazard and Operability Study) is a discussion-based method aimed at systematically identifying process deviations that could lead to hazards or operational issues.

It does not assume that an incident will occur; instead, it asks:

What happens if process parameters deviate from design intent?

HAZOP typically uses process flow diagrams (such as P&ID) in combination with:

Process parameters (flow, pressure, temperature, level, composition, etc.)

Guide words (more, less, none, reverse, earlier, delayed, etc.)

The structured discussion identifies:

Possible deviations

Causes of these deviations

Consequences of these deviations

Existing protective measures

Whether improvements are necessary

HAZOP is typically the starting point for process safety work. It lays out the risks on the table, but it doesn’t answer whether the existing protections are adequate. That’s where LOPA comes into play.

2. LOPA Analysis

LOPA (Layer of Protection Analysis) converts the phrase “We have many protections” into a clear, auditable judgment. It uses a semi-quantitative approach to assess key accident scenarios.

Starting from the initiating event, LOPA evaluates whether the residual risk after multiple layers of protection can be reduced to an acceptable level. If it’s not low enough, it specifies how much additional risk reduction is needed.

In LOPA, an accident scenario is typically broken down into four parts:

Initiating event (e.g., equipment failure, operator error, clogging, leakage)

Independent Protection Layers (IPL)

The reliability of each protection layer (can it act effectively when needed?)

The residual risk (compared to corporate risk tolerance)

LOPA focuses on IPLs. For a protection measure to be considered an IPL, it must meet the following criteria:

Independence: It should not share failure modes with the initiating event or other protections.

Effectiveness: It must be able to mitigate the scenario.

Auditability: It must be testable, maintainable, and verifiable over time.

Response time matching: It must be able to react quickly enough to the developing incident.

LOPA’s strength lies in its ability to strike a balance between “clear quantification” and “practical application.” It provides actionable conclusions for decision-making, such as:

Is the current protection adequate?

If not, how much more risk reduction is required?

If LOPA determines that additional protection is needed, the question becomes: How reliable does the safety instrument system (SIS) need to be? That’s where SIL levels come in.

3. SIL Levels

SIL (Safety Integrity Level) is derived from IEC 61508/IEC 61511 standards and essentially defines the reliability requirements for safety instrument functions (SIF). It answers the question: How reliable does the SIF need to be to reduce risk to an acceptable level?

SIL is not a rating for individual components but for the entire safety function chain (sensor, logic solver, actuator) under specific operating conditions and demand modes.

In process industries, the most common mode is low-demand mode, where the PFDavg (probability of failure on demand) is used to measure reliability. In high-demand or continuous modes, PFH (probability of failure per hour) is more commonly used.

From a functional perspective, SIL is a tool that “engineers safety requirements.” It provides clear, quantifiable guidelines for design, implementation, and verification, focusing on ensuring that the function works reliably when needed.

SIL is typically introduced after LOPA confirms the need for a SIF. It doesn’t answer “Do we need a safety function?” but rather “If we need one, how reliable must it be?”

The implementation of SIL is made possible through:

Architecture and redundancy choices (e.g., 1oo1, 1oo2, 2oo3)

Failure probabilities and common cause failure considerations (diagnostic, bypass, β-factor approach, etc.)

Proof test intervals, coverage, and maintenance strategies

Change management and functional testing throughout the operational lifecycle

These steps collectively ensure that a safety function meets the required SIL and not just the component certification. Hence, a valve or transmitter with a SIL certificate proves it has certain capabilities, but whether the system achieves the target SIL depends on system design, verification, and long-term operation.

4. Comparison of HAZOP, LOPA, and SIL

Here’s a functional comparison of the three tools:

| Dimension | HAZOP | LOPA | SIL |

|---|---|---|---|

| Main Goal | Identify hazards and deviations | Assess if the risk is acceptable | Define the reliability of safety functions |

| Focus | What could happen | Is the risk low enough? | How reliable should the function be? |

| Analysis Type | Qualitative | Semi-quantitative | Quantitative/Standardized |

| Typical Output | Scenarios and suggestions | Risk assessment and required risk reduction | SIL level |

| Engineering Stage | Early design or modification | Risk assessment phase | Design and implementation phase |

5. Integrating the Three Tools

Let’s take the example of a reactor overpressure leading to a release:

HAZOP will generate possible deviations (e.g., high/overpressure), discuss causes (e.g., blocked outlet, valve malfunction, runaway exothermic reaction, nitrogen seal failure), and the consequences (overpressure → release/burst → toxic or flammable release). Existing protections like control loops, alarms, PSVs, interlocks will be listed.

LOPA will focus on key scenarios, breaking down the chain into “initiating event → protection layer → residual frequency” and assessing which protections qualify as IPLs (independence, auditability, response time). It will calculate whether residual risk meets company guidelines and specify any gaps in risk reduction.

SIL will step in to define the required reliability (RRR) of the safety instrument system (SIF) and guide its design, verification, and maintenance.

6. Summary

In practice, HAZOP, LOPA, and SIL are used sequentially and as needed:

HAZOP systematically identifies potential hazardous scenarios.

LOPA assesses if the risk is acceptable for critical scenarios.

SIL defines the reliability requirements for safety functions.

They are not competing tools, but complementary components of a comprehensive process safety analysis system.