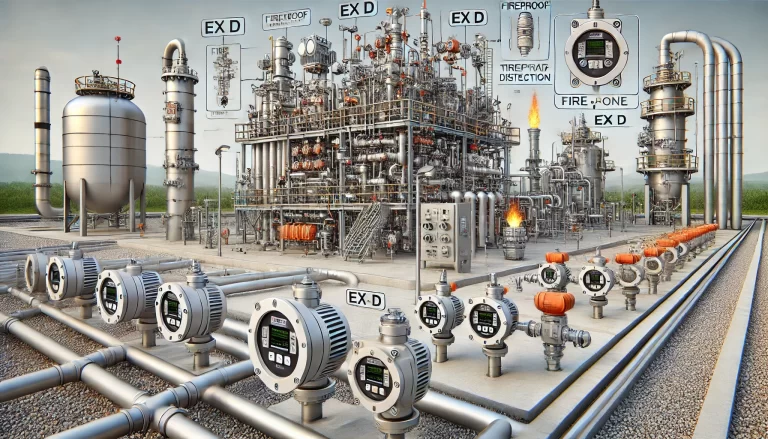

Automation instrumentation plays a critical role in industrial control systems as the “peripheral nerves” of production. When such equipment reaches the end of its life due to aging, damage, or obsolescence, a standardized decommissioning and disposal process is essential to ensure compliance, safety, and efficient asset turnover.

This document outlines the key steps, standards, and best practices for managing the disposal of automation instrumentation in industrial settings.

1. Scope and Management Framework

The disposal of automation instrumentation assets falls under the enterprise’s fixed asset management system. The process should follow established internal management procedures, such as corporate regulations and detailed implementation guidelines.

Typical management elements include:

Disposal conditions and criteria

Approval authorities and workflows

Handling of physical equipment

Documentation and traceability

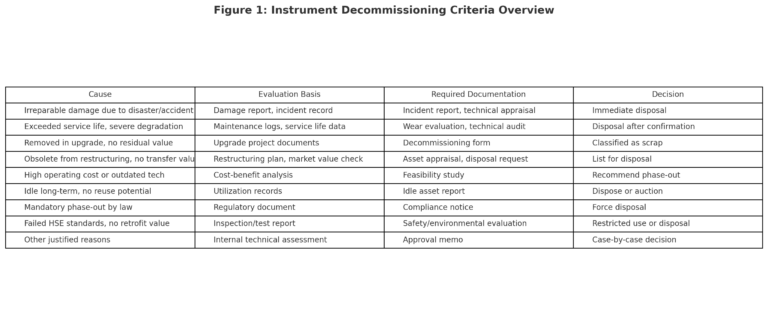

2. Disposal Criteria

Instrumentation assets should be considered for decommissioning under any of the following conditions:

a) Severely damaged or lost due to natural disasters or accidents, and deemed irreparable.

b) Reached end-of-life with serious wear, no longer repairable or economically viable.

c) Removed due to upgrades or retrofits and has no residual value.

d) Phased out due to business restructuring, with no market or internal transfer value.

e) Technologically obsolete or high operating costs that do not meet production needs.

f) Idle for extended periods with no foreseeable reallocation potential.

g) Subject to mandatory phase-out under national regulations.

h) Failed to meet HSE (Health, Safety, Environmental) standards upon inspection, with no feasible rectification.

i) Other justified reasons based on technical or operational assessments.

3. Approval and Application Process

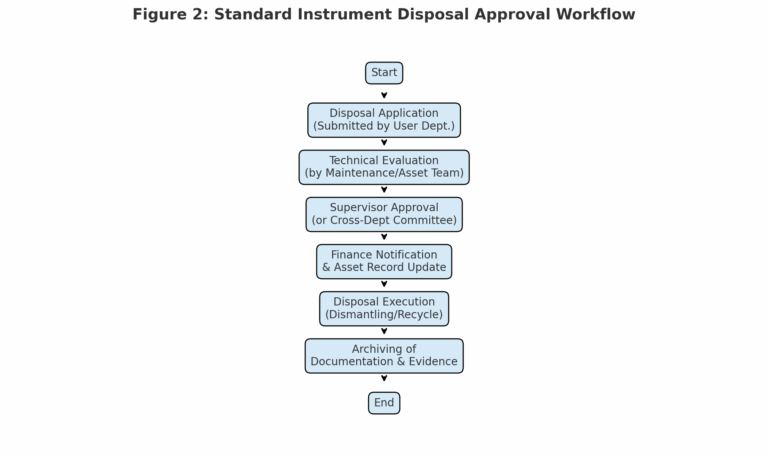

A typical approval workflow includes the following steps:

Initiation:

Operating departments submit a “Disposal Application Form,” specifying equipment details and reasons for decommissioning.Technical Evaluation:

On-site assessment by asset management or instrumentation teams. If required, a formal technical assessment or fault report is attached.Approval Process:

Routine disposals are approved by department managers.

Critical or high-value equipment may require cross-departmental verification or expert review.

Documentation:

All forms, evaluation records, and approvals must be archived.

4. Disposal and Handling Methods

Once approved, the equipment is handled according to its remaining value and material status:

Reusable Assets: Sold or transferred within or outside the company after data cleansing and basic refurbishment.

Scrap Equipment: Safely dismantled. Components and materials are categorized (e.g., metals, plastics, hazardous materials) for compliant disposal.

Supervision: Disposal must be documented via photos or videos and supervised by asset or equipment management staff.

Finance Audit: Fixed asset account updated accordingly, with written-off records retained.

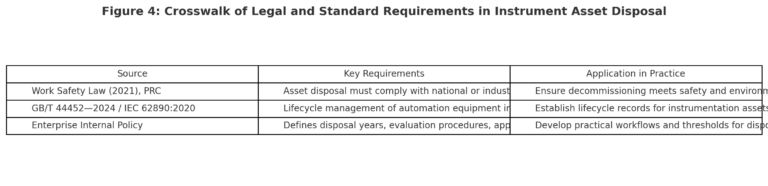

5. Applicable Laws and Standards

| Source | Title | Application |

|---|---|---|

| PRC Law | Article 36 of the Work Safety Law of the People’s Republic of China (2021) | Disposal must comply with national or industry standards |

| National Standard | GB/T 44452—2024 / IEC 62890:2020 | Industrial-process measurement, control and automation – Lifecycle management |

| Internal Policy | Enterprise-specific fixed asset management policies | Customized disposal thresholds, asset lifespan, evaluation metrics |

6. Recommendations for Implementation

Establish a clear disposal database and update it regularly.

Define lifespan benchmarks for each instrument category (e.g., 5–10 years for pressure transmitters).

Standardize technical appraisal procedures (e.g., calibration records, fault logs).

Promote green dismantling and recycling, aligning with ESG and sustainability goals.

Ensure traceability through asset coding, disposal records, and image archiving.