A paperless recorder is an essential tool for industries requiring reliable and efficient data recording and monitoring. This guide provides comprehensive instructions on selecting the optimal paperless recorder based on specific requirements.

1. Dimensions and Panel Cutout Sizes

Paperless recorders typically come in several standard dimensions:

144×144mm (5.6-inch LCD): Panel cutout 138×138mm

185×156mm (7-inch LCD): Panel cutout 138×138mm

288×288mm (10.4-inch LCD): Panel cutout 282×282mm

160×80mm: Panel cutout 152×76mm

80×160mm: Panel cutout 76×152mm

When selecting the size:

To replace traditional small-sized recorders (paper-based or electronic), choose 144×144mm to maintain existing panel cutouts.

To replace medium-sized traditional recorders, select the 288×288mm version. Note that slight modifications to the panel cutout might be necessary.

Large traditional recorders might not have direct replacements due to size constraints.

Generally, smaller-sized recorders (144×144mm and 185×156mm) are more cost-effective than larger (288×288mm) counterparts.

2. Determining the Number of Input Channels

The number of input channels is determined by the number and types of external signals connected to the recorder. Common inputs include:

Current signals

Voltage signals

Thermocouples

RTD (Resistance Temperature Detectors)

Frequency signals

Resistance signals

Key considerations:

“Universal input” typically includes standard voltage, current, thermocouple, and RTD signals. Frequency and customized signals require special attention.

Check manufacturer specifications, as maximum frequency input limits vary by brand.

For flow measurement:

Simple flow measurement without temperature and pressure compensation counts as one input channel.

Flow measurement requiring temperature and pressure compensation counts as three input channels.

3. Functionality and Optional Features

Standard features typically include:

Universal signal input

Display and recording capabilities

Graphical data representation

AC220V power supply

Chinese language interface

USB port

Standard internal memory

Optional features (incurring additional costs) include:

Alarm outputs

DC24V loop power supply

Analog retransmission outputs

Communication interfaces (RS485, Ethernet)

PID control

Flow calculation functions

Custom frequency or special signal inputs

Expanded internal memory

Additional storage (USB drives, SD cards)

Multi-language interfaces

Carefully evaluate which options are essential to avoid unnecessary costs.

4. Software Considerations

Recorder software typically comes in two versions:

Single-recorder software (free):

Connects one recorder to a PC using standard RS232 communication for data viewing and management.

Multi-recorder software (paid):

Connects multiple recorders to a single PC via RS485 for centralized monitoring and data management.

Consider software requirements carefully based on the number of recorders and data integration needs.

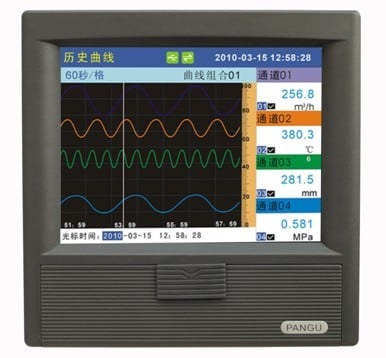

5. Screen Options: Blue Screen vs. Color Screen

Both versions generally offer similar functionalities, with key differences:

Color Screens:

Can display multiple data curves simultaneously using different colors, enhancing readability and monitoring convenience.

Blue Screens:

Display data in a single color, limiting simultaneous curve visualization to one.

Slightly more economical.

Choose based on operational needs, convenience, and budget constraints.

6. Pricing Calculation

Paperless recorder pricing typically follows the formula:

Total Price = Base price per channel + (Cost per additional channel × number of additional channels) + Alarm option costs + Communication option costs + DC24V supply costs + Analog retransmission costs + Other optional feature costs.

Key points:

Ethernet communication usually costs more than RS485.

Costs vary widely by manufacturer, features, and additional service support.

7. Manufacturer and Brand Selection

Brand reliability and quality can significantly affect recorder performance and longevity. Important factors to consider include:

History and Technology: Brands with a long market presence and advanced technology typically offer better stability and value.

Technical Specifications: Accuracy (commonly 0.5%, occasionally 0.2%), stability, temperature drift, electromagnetic compatibility, interference resistance, and component quality.

Production Techniques: Modern, high-quality production methods (e.g., integrated chip, modular design, SMT) ensure better reliability compared to traditional manual assembly.

User Interface and Ergonomics: Choose devices with intuitive and user-friendly interfaces, clear displays, and ergonomic design.

Warranty: Longer warranty periods often reflect manufacturers’ confidence in product quality.

Conclusion

Selecting the right paperless recorder involves understanding specific requirements around size, functionality, input channels, software compatibility, and budget. A thoughtful selection based on this guide can enhance operational efficiency, data accuracy, and overall reliability in monitoring and controlling industrial processes.