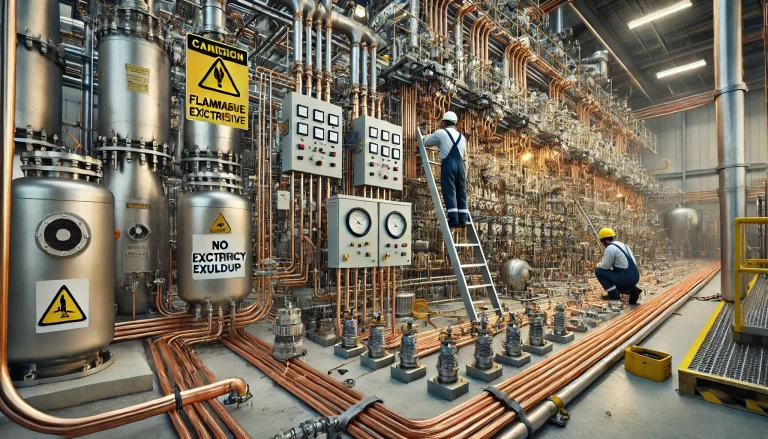

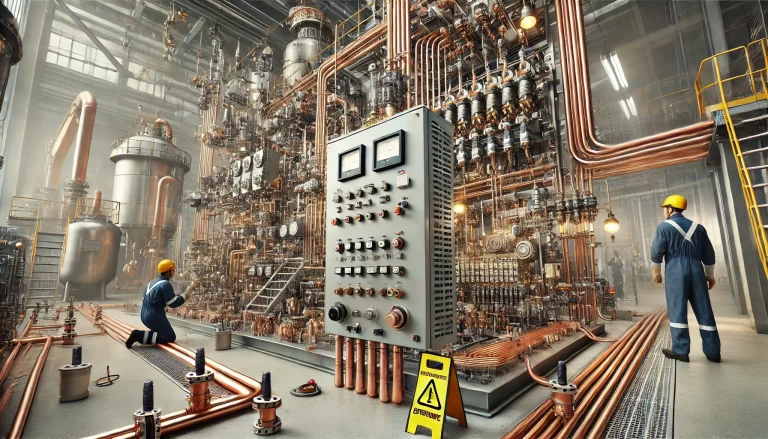

Hazardous industrial environments — such as chemical plants, oil refineries, pharmaceutical production lines, and grain processing facilities — are often at risk of explosions due to the presence of flammable gases, vapors, or dust. In such areas, proper electrical grounding (earthing) is not just a safety feature — it is a regulatory requirement that forms a critical part of explosion protection design.

This article outlines in detail the grounding requirements for hazardous locations, following the core principles found in Chinese national standards like GB 50058-2014 and GB 3836.14, and their relation to international standards such as IEC 60079-14.

🔐 1. The Purpose of Grounding in Hazardous Locations

Grounding systems in explosive atmospheres serve several vital functions:

✅ a. Preventing Static Electricity Accumulation

Certain processes (such as fluid flow, powder handling, or friction between materials) can lead to electrostatic charges building up on equipment surfaces. In explosive atmospheres, a discharge of static electricity can cause ignition.

→ Solution: Use grounding to safely discharge static electricity to earth.

✅ b. Protection Against Electric Shock and Fire

In the event of insulation failure, metallic enclosures or components may become live. If they are grounded, this fault current will flow to earth, activating circuit breakers or fuses to quickly disconnect power.

→ Result: Reduced risk of fire and explosion due to electrical faults.

✅ c. Equipotential Bonding

In hazardous areas, voltage differences between equipment can also result in sparks. Grounding and bonding ensure that all conductive parts maintain the same electrical potential, eliminating the risk of spark discharge.

🛠 2. Types of Equipment and Their Grounding Requirements

🔧 a. Explosion-Proof Electrical Equipment (Ex d, Ex e, etc.)

Must be connected to a reliable grounding system.

Dedicated grounding terminals are required, marked with the standard earth symbol.

Grounding terminals should be easily accessible and mechanically robust.

The grounding conductor must be able to withstand mechanical stress and carry expected fault current.

🧯 b. Equipment with Non-Metallic or Antistatic Enclosures

If made of plastic or other non-conductive material, it must be antistatic by design.

Surface resistance or volume resistance must be below defined safety thresholds (typically ≤10⁹ Ω).

If necessary, static discharge paths (such as conductive fibers or grounding strips) must be provided and connected to ground.

⚙️ c. Portable or Mobile Equipment (e.g. inspection lamps, analyzers)

Must include means of ensuring reliable grounding during use — via grounding contacts, conductive housing, or grounded power cords.

In Zone 0 or Zone 1 areas, this is especially critical to avoid spark risk.

🪛 d. Instrumentation Wiring and Cable Shielding

Metal cable trays, armor, or shielding layers must be bonded and grounded.

Typically, shielding is grounded at one end only to avoid ground loops.

Use of intrinsically safe systems (Ex i) requires special grounding measures to maintain signal integrity and prevent interference.

🧲 3. Static Electricity Grounding Systems

Key Considerations:

Grounding conductors should be made of copper or galvanized steel.

Static discharge points should maintain a resistance to ground below 100 ohms (as a typical target).

In many cases, lower resistance (e.g., <10 ohms) is desirable for critical equipment.

Regular inspection and testing of grounding continuity and resistance is essential.

In systems handling flammable liquids (e.g., tanker trucks, fuel dispensers), grounding clamps must be attached before loading/unloading begins.

📌 4. Installation Best Practices and Prohibited Practices

✅ Required Practices:

Create a common grounding network for all metallic structures and enclosures.

Use short, direct paths to ground with minimal loop areas to reduce inductive effects.

In some designs, grounding systems are combined with lightning protection systems, but care must be taken to avoid interference.

❌ Prohibited Practices:

Never use the neutral conductor as a grounding path.

Do not rely on flexible conduit or metallic hoses as a grounding path unless they are specifically designed and tested for that purpose.

Do not mix protective grounding with process piping unless proper bonding is ensured.

Avoid multiple, uncoordinated grounding points that may result in potential differences and circulating currents.

🔎 5. Grounding Resistance Targets

| Purpose | Recommended Ground Resistance |

|---|---|

| Equipment Protective Grounding | ≤ 4 ohms |

| Static Electricity Discharge | ≤ 100 ohms |

| Sensitive Electronics (e.g., Ex i systems) | ≤ 1 ohm preferred |

| Lightning Protection System | As per design standard, often ≤ 10 ohms |

📝 6. Compliance and Documentation

All grounding systems must be included in the hazardous area classification drawings and electrical single-line diagrams.

Periodic testing and documentation are mandatory — many plants require quarterly or annual ground resistance checks.

Changes to grounding configuration must go through a management of change (MOC) process to ensure safety compliance.

🧭 Conclusion

In hazardous locations, a well-designed and properly maintained grounding system is not optional — it’s fundamental to explosion safety. Whether you’re dealing with static discharge prevention, fault current return paths, or ensuring equipotential bonding, grounding plays a central role in your overall safety strategy.

For system integrators, instrumentation engineers, or EHS professionals, understanding the specific grounding requirements for different types of equipment and environments is essential for regulatory compliance and personnel safety.