Introduction

Gas flow standard devices are essential instruments used for calibrating and measuring gas flow in various industrial and scientific applications. These devices ensure the accuracy and traceability of gas flow measurements, thereby improving efficiency, safety, and compliance in sectors such as metrology, energy, environmental monitoring, and manufacturing.

This article explores the types, working principles, applications, and technical specifications of gas flow standard devices, providing a detailed understanding of their significance in modern industries.

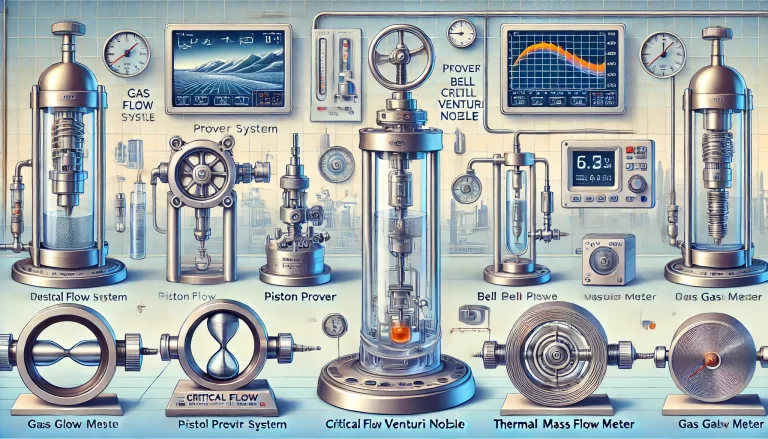

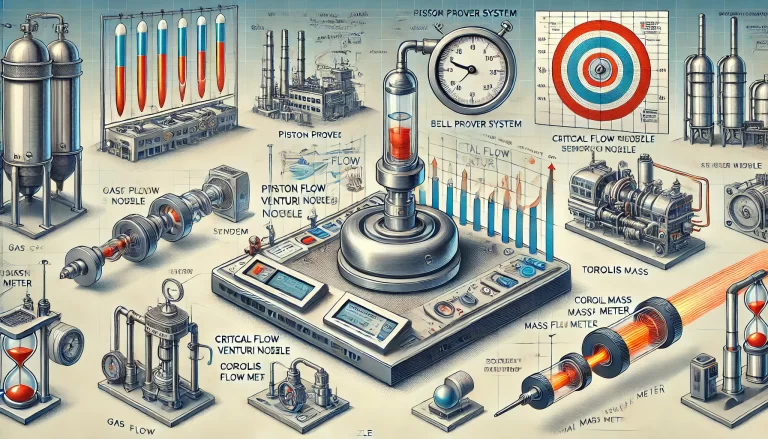

Types of Gas Flow Standard Devices

Gas flow standard devices are categorized based on their measurement principles and methods. The most commonly used types include:

1. Volumetric (Displacement) Method

This method uses a container of known volume to measure gas flow by monitoring the displacement over time. Key devices in this category include:

Piston Prover Flow Standard: Uses a precision piston-cylinder system to provide highly accurate gas flow measurements.

Bell Prover System: Employs a sealed bell structure that moves in response to gas flow, measuring displacement.

Drum-type Gas Meters: Used for low-flow applications, where gas fills and displaces drum chambers sequentially.

These devices are particularly suitable for low-flow and high-accuracy calibrations.

2. Critical Flow Venturi Nozzle (CFVN) Method

In this method, gas is passed through a venturi nozzle under controlled conditions, creating a critical flow state where the gas velocity reaches sonic speed. Since the mass flow rate in this state depends only on upstream pressure and nozzle characteristics, CFVN devices provide stable, repeatable, and high-precision gas flow measurements.

Advantages of CFVN systems include:

High measurement repeatability and accuracy.

Independence from downstream pressure variations.

Capability of handling high flow rates.

3. Mass Flow Measurement Method

This method measures the mass of gas flowing through a system rather than its volume, making it particularly effective for applications requiring precise gas consumption tracking. Key technologies include:

Coriolis Mass Flow Standards: Utilizes Coriolis force to determine mass flow, offering high accuracy and stability.

Thermal Mass Flow Standards: Measures gas flow based on heat transfer principles, ideal for low-flow and micro-flow applications.

4. Time-Mass Method

This method calculates flow by measuring the mass of gas collected over a known time period. A high-precision balance or gravimetric scale is typically used to weigh the collected gas, making this approach highly accurate for calibration purposes.

Applications of time-mass devices include:

Calibration of ultra-low flow gas meters.

Leakage testing in industrial and laboratory environments.

Precision flow measurements in pharmaceutical and semiconductor industries.

5. Bubble Flow Meters

This method is primarily used for micro-flow measurements, where gas is passed through a liquid, forming bubbles. The volume of the bubbles is measured to determine gas flow. Though simple, this method is effective for extremely low gas flow rates in laboratory settings.

Applications of Gas Flow Standard Devices

Gas flow standard devices are widely utilized across multiple industries, each requiring precise flow measurements for quality control, process optimization, and regulatory compliance. Major applications include:

Metrology and Calibration Laboratories: Ensuring traceability and accuracy of gas flow meters used in industrial and scientific applications.

Industrial Process Control: Monitoring and optimizing gas usage in chemical plants, oil refineries, and food processing.

Energy Sector: Gas distribution, pipeline flow measurement, and fuel consumption monitoring.

Environmental Monitoring: Measuring greenhouse gas emissions, air pollution monitoring, and ensuring compliance with environmental regulations.

Medical and Healthcare: Calibrating medical gas flow meters, respiratory devices, and anesthesia gas delivery systems.

Aerospace and Defense: Precise fuel flow measurement in jet propulsion systems and space exploration.

Key Technical Specifications of Gas Flow Standard Devices

Several factors influence the performance and selection of gas flow standard devices:

1. Flow Range

Ranges from nanoliters per minute (nL/min) for micro-flow applications to thousands of standard cubic meters per hour (Nm³/h) for large-scale industrial applications.

2. Measurement Accuracy

High-precision devices achieve uncertainties as low as 0.05% of the reading, while standard devices typically offer 0.1%–1% uncertainty.

3. Operating Pressure and Temperature

Designed to function under a broad range of pressure and temperature conditions, depending on the application (e.g., high-pressure pipeline gas flow measurement or low-temperature cryogenic applications).

4. Calibration and Traceability

Devices should be calibrated against national or international metrology standards (e.g., NIST, ISO, OIML) to ensure accuracy and traceability.

Future Trends and Developments

With advances in digital technology and automation, gas flow standard devices are evolving to become more sophisticated and efficient. Key trends include:

Integration with IoT and AI: Real-time data transmission and AI-driven analytics improve monitoring and diagnostics.

Miniaturization and Portability: Compact and mobile calibration systems enable on-site verification of flow meters.

Higher Accuracy and Lower Uncertainty: Continuous improvement in sensor technology enhances measurement reliability.

Sustainability and Energy Efficiency: Development of eco-friendly and energy-efficient flow measurement solutions.

Conclusion

Gas flow standard devices play a crucial role in ensuring accurate and reliable gas flow measurements across various industries. By understanding the different types, principles, and applications of these devices, industries can optimize their processes, comply with regulations, and improve operational efficiency. As technology advances, these devices will continue to evolve, further enhancing precision, automation, and real-time monitoring capabilities.