Preface

Chemical instrumentation plays a crucial role in chemical engineering and process industries. These instruments are essential for measuring, controlling, monitoring, and recording various physical and chemical parameters in industrial production. They contribute significantly to enhancing production efficiency, ensuring product quality, and maintaining safety. With advancements in automation and digital technology, the scope of chemical instrumentation continues to expand, improving both performance and precision. This article provides an in-depth discussion on the definition, classification, functions, selection criteria, applications, and future trends of chemical instrumentation.

1. Definition and Role of Chemical Instrumentation

Chemical instruments are devices used for measuring, controlling, and recording various process parameters in chemical production. These parameters include pressure, temperature, flow rate, liquid level, concentration, pH value, density, and viscosity. Chemical instruments not only provide real-time monitoring of process parameters but also integrate with feedback control systems to automatically adjust process variables, ensuring operational stability and safety.

1.1 Key Functions of Chemical Instrumentation

Chemical instrumentation serves several essential functions:

Process Monitoring: Ensures that all process parameters remain within set limits, preventing fluctuations and anomalies.

Automation Control: Integrates with control systems to automate production processes, improving efficiency and reducing human error.

Safety Assurance: Detects hazardous gases, abnormal temperature, and pressure levels, triggering alarms or emergency shutdowns when necessary.

Data Recording and Analysis: Captures and logs real-time data, facilitating later analysis for optimization and reporting.

2. Classification of Chemical Instruments

Chemical instrumentation can be categorized based on measurement and control requirements. The major categories include measurement instruments, control instruments, and recording instruments.

2.1 Measurement Instruments

Measurement instruments detect physical and chemical variables and convert them into signals for monitoring and analysis. Common types include:

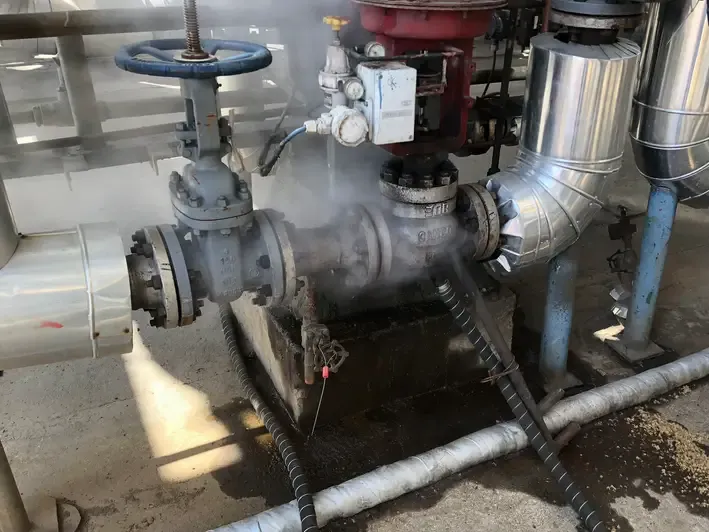

Pressure Instruments: Measure the pressure in pipelines and vessels (e.g., pressure transmitters, pressure switches, differential pressure transmitters).

Temperature Instruments: Monitor temperature changes (e.g., thermocouples, resistance temperature detectors (RTDs), infrared sensors).

Flow Meters: Measure liquid, gas, or steam flow rates (e.g., electromagnetic flow meters, turbine flow meters, ultrasonic flow meters).

Level Measurement Instruments: Detect liquid or solid material levels (e.g., float level switches, capacitance level meters, radar level meters).

Concentration Analyzers: Measure the concentration of substances in solutions (e.g., spectrometers, conductivity meters, pH meters).

2.2 Control Instruments

Control instruments receive signals from measurement devices and adjust process parameters according to predefined rules. Key examples include:

Control Valves: Regulate flow and pressure based on control signals.

PID Controllers: Implement proportional, integral, and derivative (PID) control strategies to regulate temperature, pressure, and flow.

Distributed Control Systems (DCS): Integrate multiple process control systems for centralized monitoring and automation.

2.3 Recording Instruments

Recording instruments store and display process data for operational analysis and optimization. Examples include:

Process Recorders: Log temperature, pressure, and flow rate data, displaying it in graphical or numerical form.

Data Acquisition Systems (DAQs): Aggregate data from various sensors for in-depth analysis and decision-making.

3. Selection Criteria for Chemical Instruments

Selecting appropriate chemical instrumentation is crucial for ensuring efficient and safe operations. The following factors should be considered:

3.1 Properties of the Measured Medium

Different chemical media impact instrument material selection, corrosion resistance, temperature tolerance, and pressure requirements. For instance, strong acids, bases, or flammable gases require corrosion-resistant and explosion-proof instruments.

3.2 Measurement Range and Accuracy

The required measurement range and accuracy depend on application needs. Precision processes demand high-accuracy instruments, while large-scale operations may allow for broader tolerance levels.

3.3 Environmental Conditions

Chemical production environments often involve extreme temperatures, humidity, vibrations, and contaminants. Instruments must be designed to withstand these conditions. For example, high-temperature applications may require specialized thermocouples or insulated sensors.

3.4 Maintenance and Calibration

Instruments should be easy to maintain and calibrate. Some instruments require regular cleaning or part replacements, so ease of access and servicing should be considered.

4. Applications of Chemical Instrumentation

Chemical instruments are used in various industrial processes to optimize efficiency, safety, and quality control. Below are key application areas:

4.1 Chemical Reaction Processes

Monitoring and controlling parameters such as temperature, pressure, and reactant concentration is crucial for optimizing reaction rates and product quality. PID controllers, temperature sensors, and flow meters work together to maintain stability.

4.2 Separation and Distillation Processes

Precise level, flow, and temperature measurements are essential for optimizing separation and distillation operations. Level meters, thermometers, and flow meters are widely used in these processes.

4.3 Storage and Transportation

Accurate monitoring of liquid levels, pressure, and flow rates ensures safe storage and transportation of raw materials and finished products. Instruments such as radar level meters and gas leak detectors play a crucial role in preventing leaks and ensuring safety.

4.4 Environmental Protection and Safety Monitoring

Chemical industries often release hazardous gases and wastewater. Environmental monitoring instruments such as gas analyzers, leak detectors, and pressure monitoring systems help prevent accidents and ensure regulatory compliance.

5. Future Trends in Chemical Instrumentation

With technological advancements, chemical instrumentation is evolving toward greater intelligence, automation, and precision. The following trends are shaping the future of the industry:

5.1 Smart Sensors and IoT Integration

The adoption of Internet of Things (IoT) technology allows for remote monitoring and predictive maintenance, reducing downtime and enhancing efficiency.

5.2 Artificial Intelligence and Big Data Analytics

AI-driven diagnostics and data analytics improve fault prediction, process optimization, and decision-making capabilities in industrial settings.

5.3 Wireless Instrumentation and 5G Connectivity

The development of wireless instruments using 5G and LoRaWAN enables real-time data transmission, reducing the need for complex wiring and enhancing system flexibility.

5.4 Energy Efficiency and Sustainability

Innovations in low-power sensors and energy-efficient control systems contribute to sustainable industrial practices, minimizing environmental impact.

6. Conclusion

Chemical instrumentation is a fundamental aspect of process industries, serving multiple roles in monitoring, control, and safety assurance. Selecting the right instruments is crucial for improving efficiency, product quality, and environmental compliance. As technology advances, the integration of smart sensors, IoT, AI, and wireless systems will drive the next wave of innovation in chemical instrumentation. These developments will not only enhance automation and precision but also contribute to sustainable and intelligent industrial operations.