Introduction

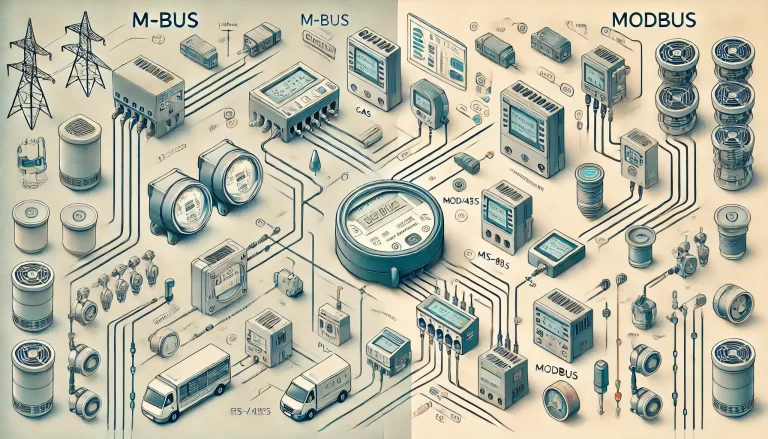

In modern industrial control and automation systems, efficient and reliable communication between devices is crucial. To ensure seamless interaction among various equipment, communication protocols play a fundamental role. One of the most widely adopted protocols in industrial automation is Modbus. First introduced in 1979 by Modicon (now a part of Schneider Electric), Modbus has evolved into a standardized communication protocol widely used in industrial environments.

This article explores the origin, core features, communication mechanisms, practical applications, challenges, and future prospects of the Modbus protocol, illustrating how it remains a cornerstone of industrial automation.

1. The Origins and History of Modbus

The Modbus protocol was originally designed by Modicon to enable communication between Programmable Logic Controllers (PLCs) and other industrial devices. Over time, its simplicity, efficiency, and open standard nature led to its widespread adoption across various industries, including manufacturing, energy, transportation, and process automation.

A key advantage of Modbus is that it operates at the application layer of the OSI model, meaning it is independent of the underlying physical communication medium. This flexibility allows Modbus to be implemented over different transport layers, such as RS-232, RS-485, and TCP/IP-based Ethernet networks.

Despite significant advancements in industrial communication technology, Modbus remains a reliable and cost-effective solution for many automation tasks today.

2. Core Features of Modbus

2.1 Master-Slave Architecture

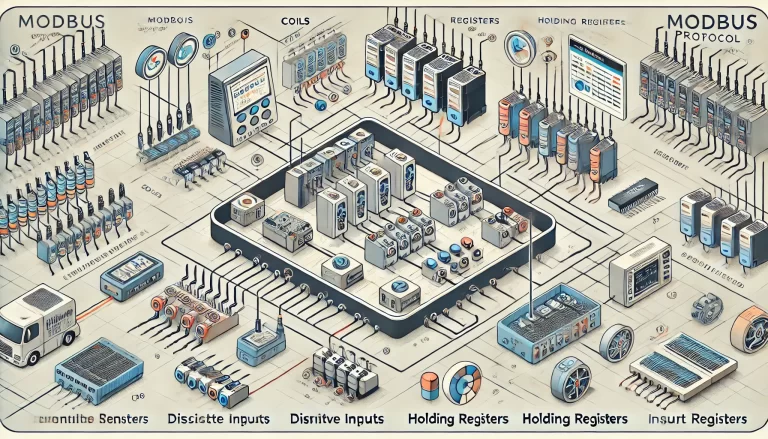

Modbus follows a master-slave communication model, where a master device (such as a PLC or computer) initiates communication with one or more slave devices (such as variable frequency drives, sensors, or actuators). The master sends commands, while the slave devices respond with requested data or perform the specified action.

This structured approach ensures an organized and efficient communication process, making it suitable for industrial environments where real-time control and data acquisition are critical.

2.2 Multiple Communication Modes

Modbus supports various communication mediums, including:

Serial Communication: RS-232, RS-485 (Modbus RTU and ASCII modes)

Ethernet-Based Communication: Modbus TCP/IP

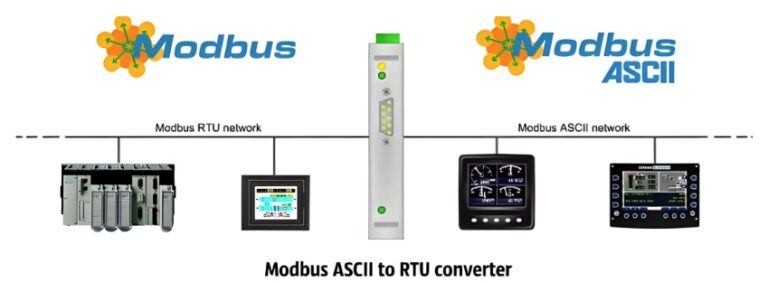

Among these, Modbus RTU is preferred for industrial environments due to its efficient data encoding and low communication overhead, while Modbus TCP/IP is commonly used in modern Industrial Internet of Things (IIoT) and SCADA systems for faster and more scalable networking.

2.3 Simple Command Structure

One of Modbus’s greatest strengths is its simple and intuitive command structure. Each Modbus request includes:

Device Address (Identifies the target slave device)

Function Code (Defines the operation, such as reading or writing data)

Data Field (Contains specific register addresses and values)

Error Check (Ensures data integrity)

The protocol supports reading and writing both discrete and analog values, making it ideal for industrial monitoring and control applications.

3. Modbus Data Transmission Mechanisms

3.1 ASCII vs. RTU Transmission Formats

Modbus supports two primary data encoding formats:

ASCII Mode: Transmits data as human-readable ASCII characters (useful for debugging and troubleshooting)

RTU Mode: Uses compact binary encoding, which improves efficiency and transmission speed, making it the preferred format in industrial environments.

3.2 Relative vs. Absolute Addressing

Modbus uses relative addressing, meaning that register addresses are defined as an offset from a base address rather than a fixed physical address. This allows greater flexibility and reduces conflicts when managing multiple devices within a network.

4. Real-World Applications of Modbus

4.1 Reducing Wiring Complexity and Costs

Traditional industrial communication systems often rely on extensive point-to-point wiring, leading to increased installation complexity and maintenance costs. Modbus enables multiple devices to be connected over a single communication bus, significantly reducing cabling requirements and improving maintainability.

4.2 Interoperability Between Devices from Different Manufacturers

One of Modbus’s key advantages is its vendor-neutral nature. Unlike proprietary protocols, Modbus allows devices from different manufacturers to communicate seamlessly, making it ideal for integrating various industrial equipment in a single automation network.

4.3 Large-Scale Device Management

Modbus can support up to 247 slave devices in a single RS-485 network. This makes it suitable for large-scale automation scenarios, such as:

Manufacturing plants (controlling multiple production machines)

Energy management systems (monitoring solar panels, wind turbines, or power grids)

Building automation (HVAC control, lighting systems, and security management)

5. Challenges and Future of Modbus

5.1 Challenges Facing Modbus

Despite its widespread adoption, Modbus has some limitations:

Limited speed: Modbus RTU operates at relatively low baud rates (typically up to 115.2 kbps), making it less suitable for high-speed applications.

Lack of built-in security: Traditional Modbus implementations do not include authentication or encryption, making them vulnerable to cyber threats in networked environments.

Scalability issues: While Modbus TCP improves scalability, it may still struggle with high-volume data exchanges compared to modern high-performance industrial protocols.

5.2 Comparing Modbus to Other Industrial Protocols

To address its limitations, alternative industrial communication protocols have emerged, including:

Profinet (Preferred for high-speed factory automation)

EtherCAT (Superior for real-time motion control)

CANopen (Common in automotive and embedded systems)

However, Modbus remains popular due to its simplicity, reliability, and wide industry support, particularly for legacy systems and cost-sensitive applications.

5.3 The Future of Modbus: Modbus TCP/IP and IIoT Integration

The evolution of Modbus TCP/IP has significantly expanded the protocol’s capabilities, enabling faster speeds, network-based scalability, and remote monitoring over Ethernet. Additionally, Modbus is being integrated with IIoT platforms and cloud-based industrial solutions, ensuring its relevance in next-generation automation.

6. Conclusion

Modbus remains one of the most widely used and fundamental communication protocols in industrial automation. Its simple architecture, cost-effectiveness, and broad compatibility have enabled it to withstand decades of technological advancements.

Although challenges such as limited speed and lack of security exist, ongoing improvements in Modbus TCP/IP and its integration with modern networking technologies ensure that Modbus will continue to play a crucial role in industrial communication for the foreseeable future.