Preface

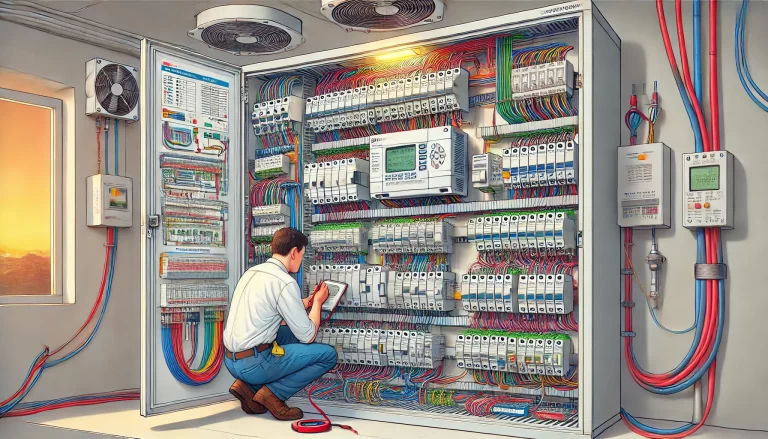

Programmable Logic Controllers (PLCs) play a critical role in industrial automation, being widely used across various production lines and control systems. As automation systems grow more complex and intelligent, the quality and reliability of PLC programming become paramount for ensuring system safety and efficiency.

This article delves into best practices for PLC programming while analyzing common errors, providing engineers with insights to optimize their programming processes and avoid frequent mistakes.

Best Practices in PLC Programming

1. Standardized Programming

Standardization enhances readability, maintainability, and scalability of the code. Below are key suggestions for achieving standardization:

Use comments and documentation: Each program block, function block, or critical logic decision should include clear comments. Documentation should outline the program’s design philosophy, the functionality of each module, and the definitions of inputs and outputs.

Modular programming: Divide complex programs into smaller, task-specific modules. This improves code reusability and makes maintenance more manageable.

2. Follow Naming Conventions

Descriptive and consistent naming conventions improve code clarity. Adopt the following principles:

Input and output points: Use intuitive names like

IN_ConveyorStartorOUT_ValveOpento indicate the variable’s purpose.Function blocks and subprograms: Ensure that each block’s name reflects its purpose, such as

MotorControlorPumpStartStop.

3. Combine Ladder Diagrams (LD) and Structured Text (ST)

While ladder diagrams are a staple in PLC programming, structured text offers efficiency for complex calculations and data processing. Use a hybrid approach where possible:

Implement control logic and interlocks in ladder diagrams for better visualization.

Use structured text for advanced computations or large-scale data manipulation to streamline code.

4. Proper Use of Timers and Counters

Timers and counters are essential but should be used judiciously:

Timers: Consolidate timer settings where possible. Use multiple timers only for distinctly separate timing requirements.

Counters: Avoid unconditional resets. Always design logical conditions to control when counters are reset to prevent erratic behavior.

5. Design for Fault Tolerance and Robustness

Anticipate hardware failures or sensor malfunctions and ensure the program can handle anomalies safely:

Error detection and alarms: Design mechanisms to detect out-of-range sensor inputs or monitor PLC health. Trigger alarms when abnormalities occur.

Redundancy: Use redundant PLCs or modules in critical systems. If one fails, the backup module should seamlessly take over.

6. Optimize Program Execution

Optimizing execution can improve responsiveness and reduce resource usage:

Simplify logic by eliminating redundant conditions.

Plan I/O update cycles thoughtfully to avoid unnecessary scans.

Minimize frequent data transfers by leveraging local calculations or caching.

Common Errors in PLC Programming

1. Unclear Naming of Variables and I/O

Inconsistent or vague names for variables and I/O points can complicate maintenance. Always ensure variable names are descriptive and adhere to established conventions to enhance collaboration.

2. Ignoring Real-Time Requirements

Failure to consider real-time constraints can cause issues like system lags or failures. Address this by:

Setting appropriate scan cycle times.

Prioritizing tasks based on their importance to system performance.

3. Misuse of Timers and Counters

Improperly configured timers (e.g., excessively short intervals) or counters with ambiguous reset conditions can disrupt operations. Ensure each timer and counter is clearly controlled within logical boundaries.

4. Overreliance on Hardware I/O

Heavy reliance on hardware I/O can overload the PLC’s resources. Optimize by:

Offloading non-critical tasks to software logic.

Reducing the number of I/O operations whenever possible.

5. Overly Complex Programs

Overly detailed code can be difficult to debug and prone to errors. Strive for simplicity without sacrificing necessary functionality.

6. Lack of Fault Detection and Recovery

Neglecting fault detection mechanisms can lead to prolonged downtime or accidents. Incorporate recovery logic to handle unexpected scenarios effectively.

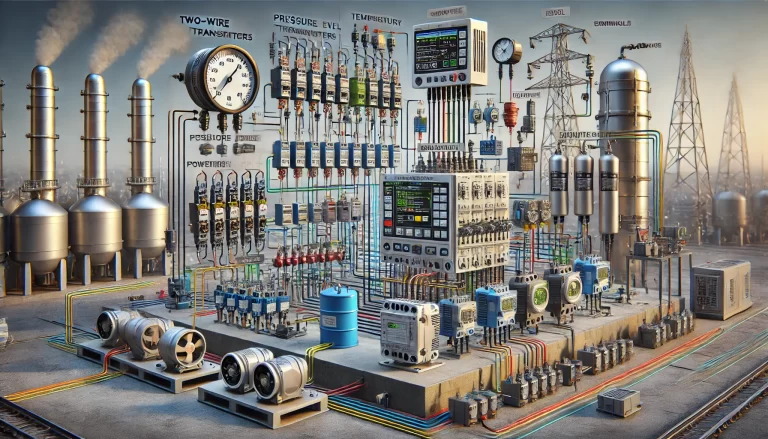

7. Ignoring Compatibility with Other Devices

PLC systems often need to communicate with external devices. Mismatched protocols or unstable connections can disrupt operations. Pay attention to:

Selecting appropriate communication protocols such as MODBUS or Ethernet/IP.

Ensuring consistent configuration across devices.

Conclusion

PLC programming requires precision, efficiency, and safety-conscious design. By adhering to best practices—such as standardized programming, thoughtful use of timers and counters, and robust fault-tolerance mechanisms—engineers can improve the reliability and performance of control systems.

Avoiding common pitfalls like unclear naming, neglecting real-time constraints, or overcomplicating programs is equally critical. Additionally, designing for compatibility and optimization ensures long-term system stability. Through careful planning and diligent execution, PLC programming can drive the success of industrial automation systems.