Accurate and reliable flow measurement requires periodic calibration. However, calibration intervals vary significantly depending on the instrument type, process medium, operating conditions, and industry compliance requirements.

This document provides a comprehensive, instrument-specific overview of recommended calibration periods, key technical checkpoints, calibration methods, and adjustment rules widely adopted in water treatment, chemical, oil & gas, and industrial process applications.

1. Differential Pressure Flow Meters

(Orifice plates, Venturi, V-cone flow meters)

Recommended Calibration Interval

Normal service (clean media, stable temperature/pressure): 12–24 months

Harsh service (corrosive/dirty media, high temperature/pressure): 6–12 months

Custody transfer / safety-critical loops: Every 6 months (mandatory in many jurisdictions)

Key Calibration Parameters

DP–flow linearity

Zero drift

Span accuracy

Orifice/V-cone wear (edge erosion ≥0.1 mm requires replacement)

Calibration Methods

1) Field calibration

Parallel comparison with a certified DP device

Reference measurement using a portable ultrasonic flow meter

2) Laboratory calibration

Use a certified pressure calibrator (deadweight tester or piston gauge)

Inspect orifice edge, plate flatness, surface condition

Important Notes

Remove fouling, scaling, or deposits before testing

Ensure pipeline isolation and safe depressurization

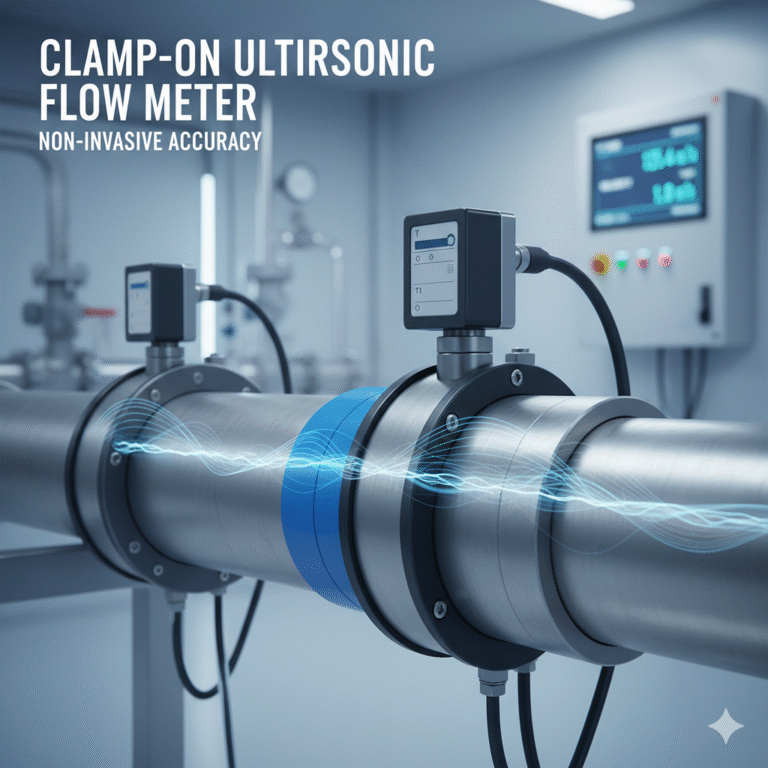

2. Ultrasonic Flow Meters

(Clamp-on, insertion, and inline types)

Recommended Calibration Interval

Clamp-on: 12–18 months (couplant aging affects transmission)

Insertion / Inline:

Clean liquids: 12–24 months

High solids/viscosity media (slurry, oils): 8–12 months

Key Calibration Parameters

Transit-time accuracy

Zero stability

Signal quality

Pipe diameter/material compensation (inline type)

Calibration Methods

1) Field calibration

Volumetric method (gravimetric/volumetric tank)

Master meter method using a certified electromagnetic or turbine meter

Reapply couplant and ensure good acoustic coupling for clamp-on units

2) Laboratory calibration

Calibration on accredited flow benches

Confirm influence of pipe thickness, roughness, and sensor positioning

Important Notes

Ensure no air bubbles in pipe

Clean outer pipe surface for clamp-on installation

3. Electromagnetic Flow Meters

Recommended Calibration Interval

Normal conductive media (water, acids, alkali): 18–24 months

Harsh media (slurry, pulp, magnetic particles): 12 months

Billing / environmental monitoring: 6–12 months (often legally required)

Key Calibration Parameters

Electrode insulation resistance

Excitation current stability

Full-scale accuracy (typically ±0.5% to ±1.0%)

Calibration Methods

1) Field calibration

Master meter comparison at multiple flow points (20%, 50%, 80%)

Offline verification by removing sensor and testing on accredited equipment

2) Operational checks

Run “zero-point verification” with no flow

If zero drift exceeds tolerance, recalibration is mandatory

Important Notes

Grounding resistance should be ≤4 Ω to avoid EMI

Clean electrode surface without scratching the liner (especially PTFE liners)

4. Turbine Flow Meters

Recommended Calibration Interval

Clean, low-viscosity liquids or gases: 12 months

Heavy oils / media with particulates: 6–8 months

Gas turbine meters: 12 months (check temp/pressure compensation)

Key Calibration Parameters

Rotor speed linearity

Bearing friction and wear

Pressure loss characteristics

K-factor stability (critical for accuracy)

Calibration Methods

1) Laboratory calibration

Liquid standard benches / sonic nozzle rigs

Recalculate K-factor; deviation > ±0.3% requires correction

2) Field inspection

Check for rotor damage, bearing looseness, fouling

Rotor must spin freely with no friction or abnormal noise

Important Notes

Verify upstream/downstream straight-run requirements (e.g., ≥10D / ≥5D)

Temperature and pressure compensation modules must be validated

5. Vortex Flow Meters

Recommended Calibration Interval

Gases/steam: 18–24 months

Liquids (clean media): 12–18 months

High-temperature steam (>300°C): 12 months

Key Calibration Parameters

Frequency–flow linearity

Sensor sensitivity and signal conditioning

Zero drift and noise filtering

Calibration Methods

1) Field calibration

Use a certified reference vortex or electromagnetic meter

For steam: record pressure & temperature to recalculate standard flow

2) Laboratory calibration

Test vortex shedding frequency under controlled flow conditions

Replace damaged piezoelectric sensors before calibration

Important Notes

Clean the bluff body to remove scale deposits

Avoid damaging the sharp edges of the vortex generator

6. Calibration Interval Adjustment Rules

1. Condition-based adjustment

If a flow meter experiences two or more failures within one cycle, shorten the interval by 50%.

2. Process change adjustment

If the medium or operating conditions change significantly (e.g., clean water → sludge), shorten interval by 30–50%.

3. Industry regulations

Chemical plants

Must comply with standards such as GB 50093-2013, limiting safety-loop instrument calibration to ≤12 months.Oil & gas / natural gas custody transfer

Follow JJG 1037-2008 and similar standards requiring calibration every 6 months.

Conclusion

Regular calibration is essential for ensuring stable, accurate, and compliant flow measurement in industrial applications. By following the recommended intervals and technical guidelines provided in this document, users can significantly reduce measurement uncertainty, extend instrument life, and comply with industry standards.

If you require calibration services, factory verification, or third-party traceable certificates, we are available to support your specific application.