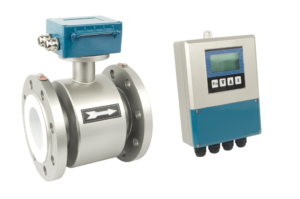

The electromagnetic flowmeter consists of a sensor and a converter. Due to the characteristics of the principle and structure, the sensor has the following main advantages:

(1) The structure is simple, there are no moving parts and disturbing parts or throttling parts that hinder the flow of the measured medium, and there will be no problems such as pipeline blockage and wear. Therefore, the electromagnetic flowmeter is particularly suitable for measuring liquid and solid two-phase media, such as conductive slurry with the suspended matter, solid particles, fibers, or high viscosity. It can be used to measure the flow of sewage, mud, mineral pulp, paper pulp, chemical fiber pulp, and other media. Because the measuring tube is a straight-through tube, there is no residual medium, and it is easy to clean and disinfect. Therefore, it is also particularly suitable for the food and pharmaceutical industries to measure the flow of special media such as corn steep liquor, fruit juice, wine, syrup, and blood.

Because there is no throttling part, when the measured medium flows in the sensor measuring tube, there is almost no pressure loss and only consumes 10-20W of electric power. Compared with the differential pressure flowmeter with throttling, its energy-saving effect is very prominent. Taking the pipe with diameter d=1m and flow qv=600m2/h as an example, when a venturi tube is used with a 40kPa differential pressure transmitter, its permanent pressure loss causes an additional consumption of about 10kW of pump power; When using an orifice flowmeter with a 40kPa differential pressure transmitter, the additional power consumption of the pump is about 32kW. As energy-saving requirements are becoming more and more urgent today, people pay attention to energy-saving, and energy-saving has become a major advantage in the development of electromagnetic flowmeters.

(2) Electromagnetic flowmeter is an instrument for measuring volume flow. Its measurement is not affected by fluid density, temperature, pressure, viscosity, Reynolds number, and changes in conductivity within a certain range. The electromagnetic flowmeter only needs to be calibrated with water as the test medium, without additional repairs and can be used to measure other conductive liquids. This is an advantage that other flow meters do not have.

(3) The electromagnetic flowmeter has a large measuring range. For the same caliber sensor, the full-scale flow rate can be set arbitrarily within the range of 0.3-15m/s, that is, the upper limit range (rangeability) is 50:1; each range can be measured linearly from 2%-100%, the range degree (tum down ) Is 50, and the total measurement range can reach 2500:1. The measurement range of electromagnetic flowmeters can cover two-speed distribution states of prime flow and laminar flow, which can not be compared with flowmeters such as differential pressure flowmeter, turbine type, and vortex flowmeter.

(4) The measurement principle is linear, and the measurement accuracy is high, up to ±0.2% to ±0.5% of the indicated value. Therefore, it can be used not only for industrial production process detection but also as a measuring instrument for trade settlement. Complete electrical signal output, fast measurement response speed, pulsating flow rate, and rapid accumulation total can be measured. With unified current, frequency signal, and digital communication signal output, it can be used for remote transmission, indication, recording, and control.

(5) Good corrosion resistance. Because the sensor is lined with materials such as rubber, fluoroplastics, or industrial ceramics, the other parts that are in contact with the measured medium are only electrodes and grounding rings. The use of different electrodes and grounding ring materials can facilitate the measurement of corrosive fluids.

(6) In principle, it is to measure the average flow velocity of the water section. The signal is divided according to the weight distribution area, and the requirement for the flow velocity distribution is relatively low. Therefore, the straight pipe sections before and after the sensor are required to be shorter than other flow meters. The installation of the sensor can be horizontal, vertical, or any angle (but the fluid is best to flow from bottom to top)

(7) It can measure the flowing fluid in positive and negative directions.

(8) Reliable use, convenient maintenance and long life.

However, the electromagnetic flowmeter cannot measure gas, steam, and liquids containing a lot of bubbles, and cannot measure liquids such as petroleum, petroleum products, and non-conductive organic solvents. Due to the temperature limitation of lining materials and electrical insulation materials, industrial electromagnetic flowmeters cannot measure high-temperature media at present.