1. Introduction

Pneumatic control valves rely on compressed air as the driving source. In case of air supply failure, the valve must move to a predefined safe position to prevent process upsets, equipment damage, or safety incidents. This pre-defined action is referred to as Fail Action, and typically includes three categories:

FC (Fail Close): Valve closes upon air supply failure.

FO (Fail Open): Valve opens upon air supply failure.

FL (Fail Locked): Valve remains at its last position when air supply is lost.

Selecting the correct fail-safe mode is a critical part of process design, ensuring compliance with safety integrity requirements (IEC 61508/61511, API, ISO, GB standards).

2. Fail Close (FC) – Fail-Safe to Closed Position

Typical Application Scenarios:

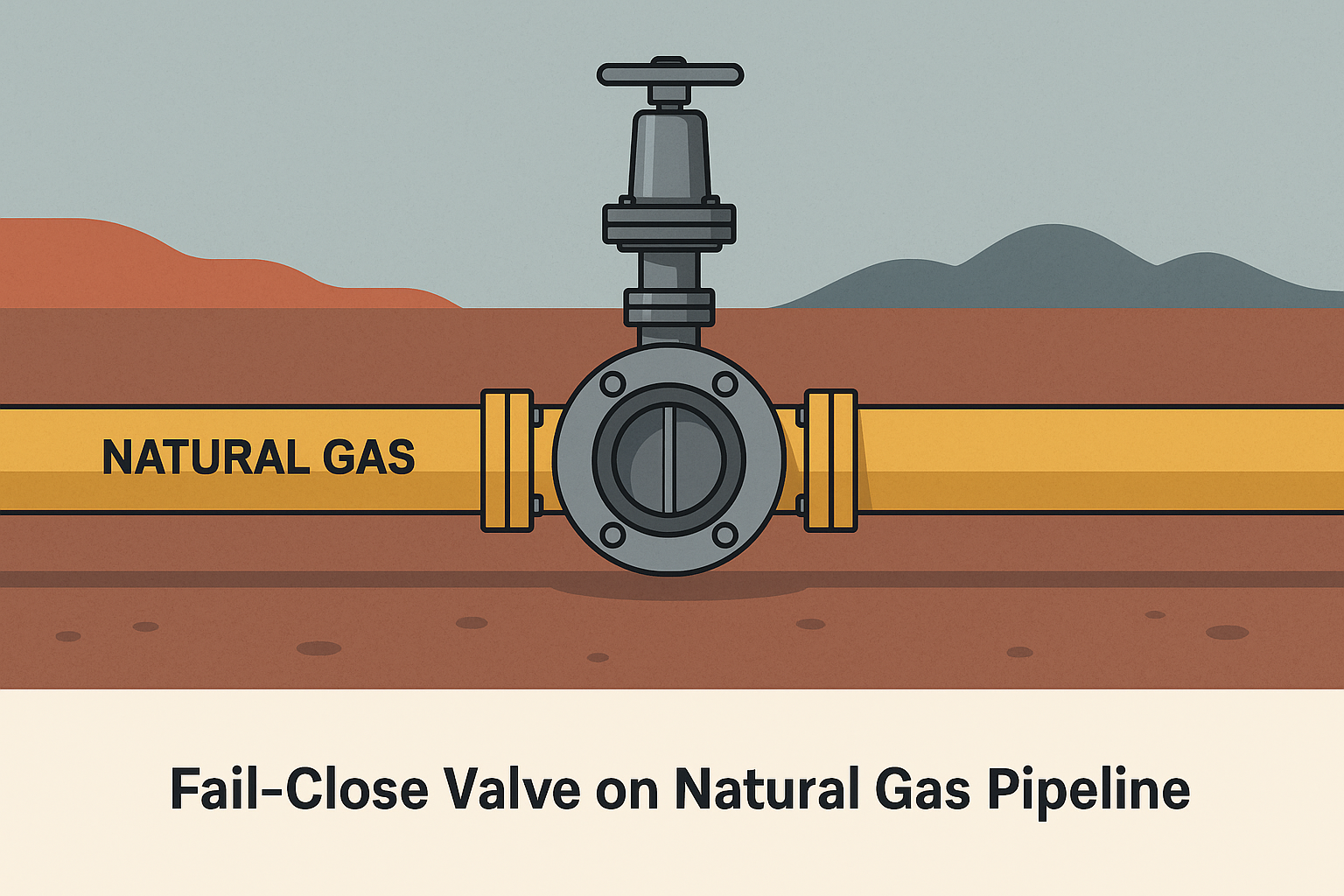

Flammable and explosive media:

In oil & gas pipelines transporting natural gas or petroleum products, fail-close valves prevent leaks and avoid explosion or fire hazards.

(Example: Pneumatic shut-off valve on natural gas transmission pipelines)Toxic or hazardous media:

In chemical plants conveying chlorine, sulfuric acid, or other toxic fluids, fail-close action blocks accidental release and safeguards personnel and the environment.Backflow prevention:

On pump discharge lines or systems where reverse flow is unacceptable, fail-close ensures media does not return and protects equipment.

3. Fail Open (FO) – Fail-Safe to Open Position

Typical Application Scenarios:

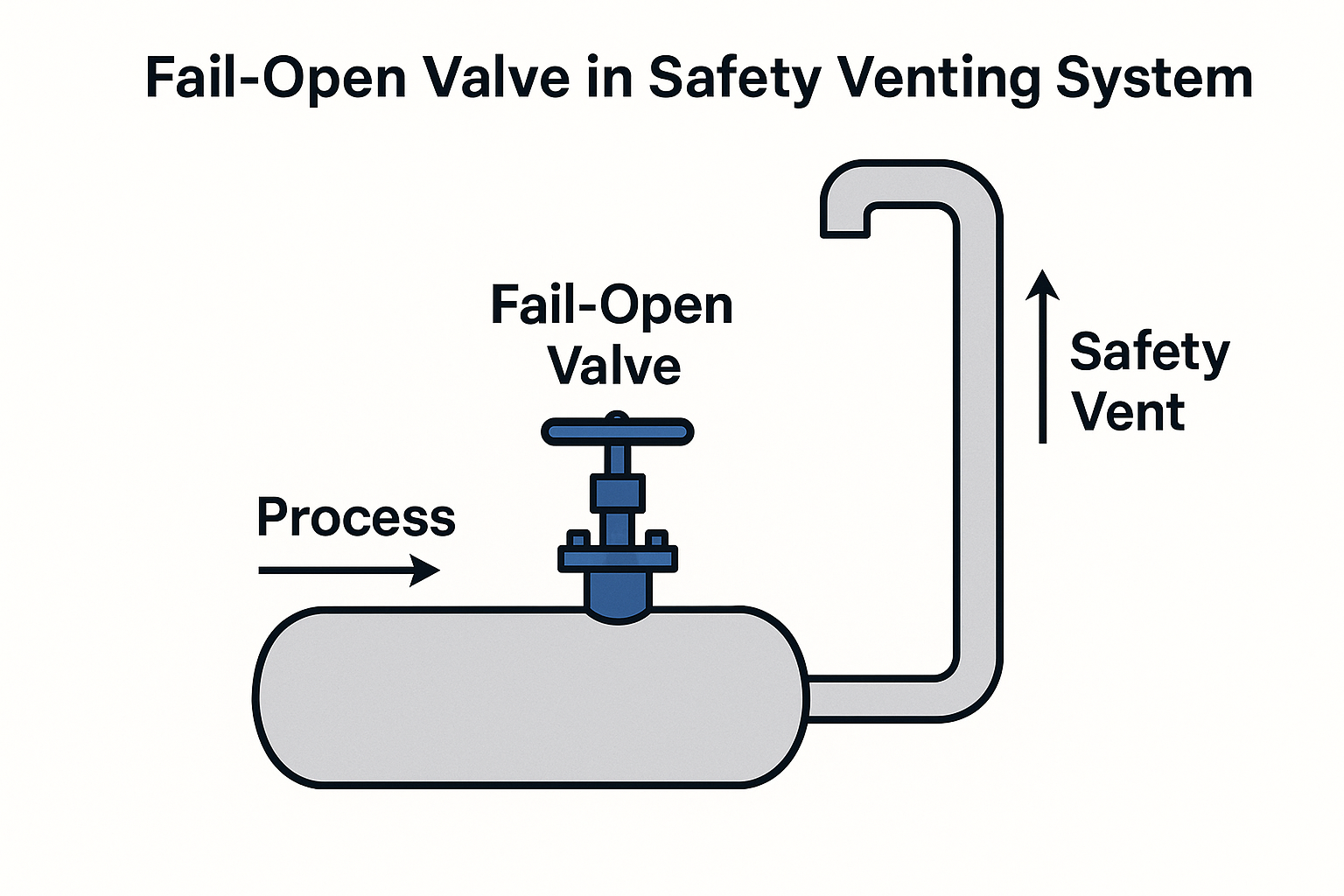

Safety venting systems:

For reactors, storage tanks, or pressure vessels, fail-open valves ensure rapid depressurization during emergencies, avoiding vessel rupture.Emergency discharge channels:

During fire or seismic events, fail-open valves secure flow of firefighting water or emergency gases.Water treatment systems:

In wastewater treatment facilities, fail-open valves maintain continuous flow from equalization tanks to downstream units, sustaining process stability.

4. Fail Locked (FL) – Fail-Safe to Locked Position

Typical Application Scenarios:

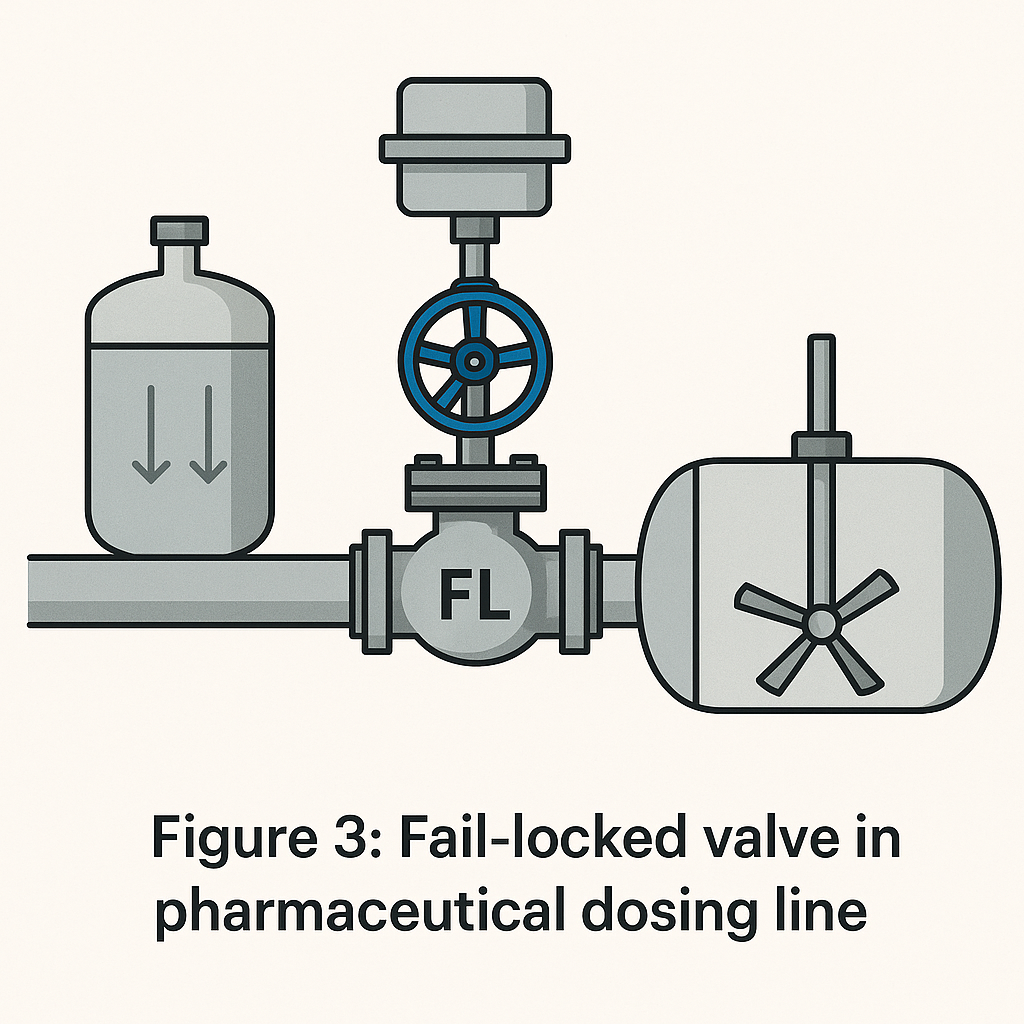

Precision-controlled processes:

In pharmaceutical batch reactors or specialty chemical dosing lines, fail-locked valves prevent sudden disturbances, ensuring product quality.High stability systems:

In power generation (steam or cooling water loops), fail-locked valves maintain steady operation, preventing system shocks caused by sudden valve movement.Intermediate position requirements:

In gas mixing systems requiring fixed blend ratios, fail-locked action freezes the valve at its current opening, maintaining temporary process stability until repairs are completed.

5. Comparative Analysis

| Fail Action | Typical Applications | Advantages | Limitations |

|---|---|---|---|

| Fail Close (FC) | Flammable/toxic media pipelines, pump discharge lines | Prevents leakage, ensures safety | May cause pressure buildup in closed systems |

| Fail Open (FO) | Safety venting, emergency discharge, wastewater flow | Ensures flow continuity, prevents overpressure | May result in material loss or uncontrolled discharge |

| Fail Locked (FL) | Precision dosing, power plant systems, gas mixing | Maintains stability, avoids sudden disturbances | Risk of process stagnation if downtime is prolonged |

6. Conclusion

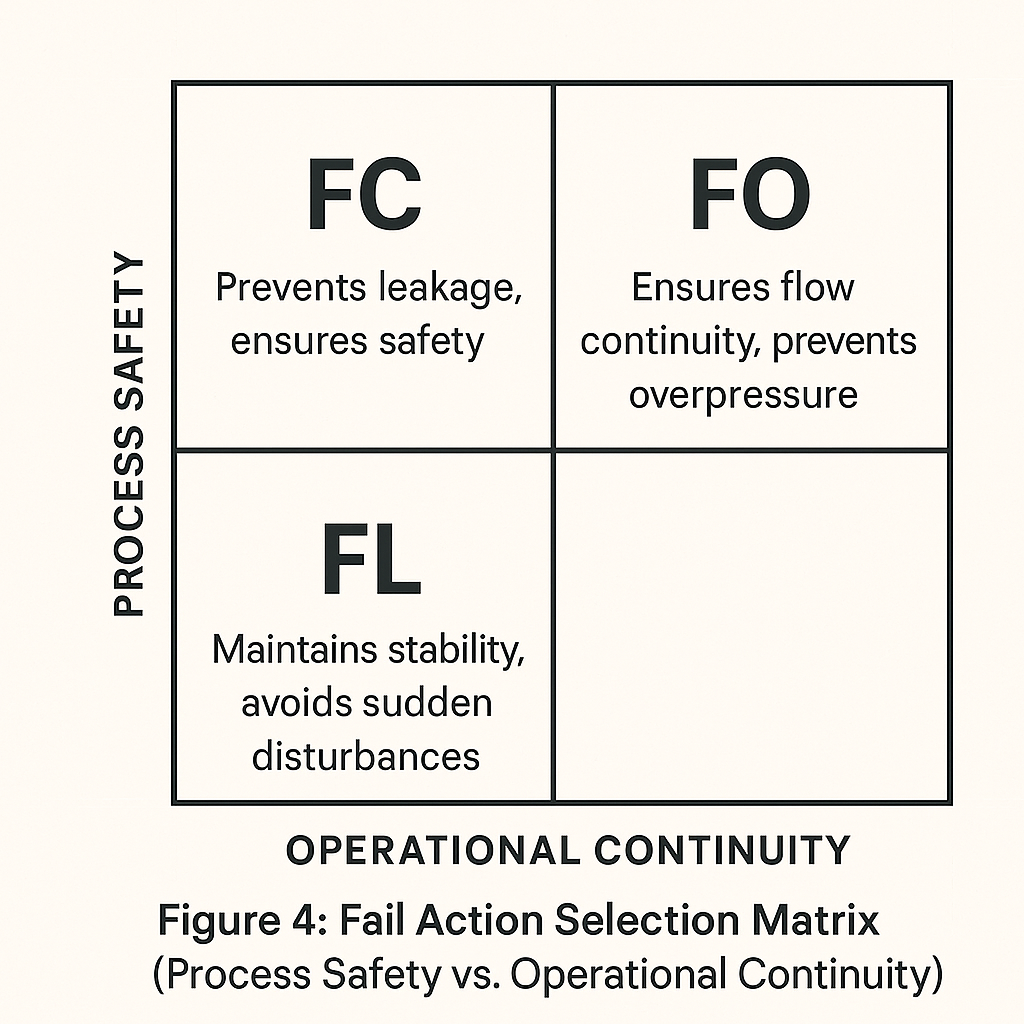

Choosing the correct fail-safe action (FC, FO, FL) depends on:

Process safety requirements (flammability, toxicity, SIL compliance).

Operational continuity (need for uninterrupted flow).

Product quality and stability (avoidance of sudden process disturbances).

By carefully evaluating process conditions, designers and engineers can ensure pneumatic valves respond appropriately to air supply failure, protecting people, environment, and assets.