The factory inspection of the transmitter is the last important step before delivery. Standardized factory inspection of the transmitter is the guarantee for every customer. The factory inspection of the transmitter should do the following:

1. Appearance inspection of the transmitter

First, the surface of the transmitter housing and parts should be smooth, intact, and free of rust and mildew. The transmitter label should be complete and clear and include: product name, model, measurement range, output, power supply and other main technical parameters.

Explosion-proof products should also have corresponding explosion-proof logos, and the high and low pressure ends of the differential pressure transmitter should also be clearly marked. Transmitters with displays need to be powered on to check whether the numbers are clearly displayed and whether there are any missing strokes.

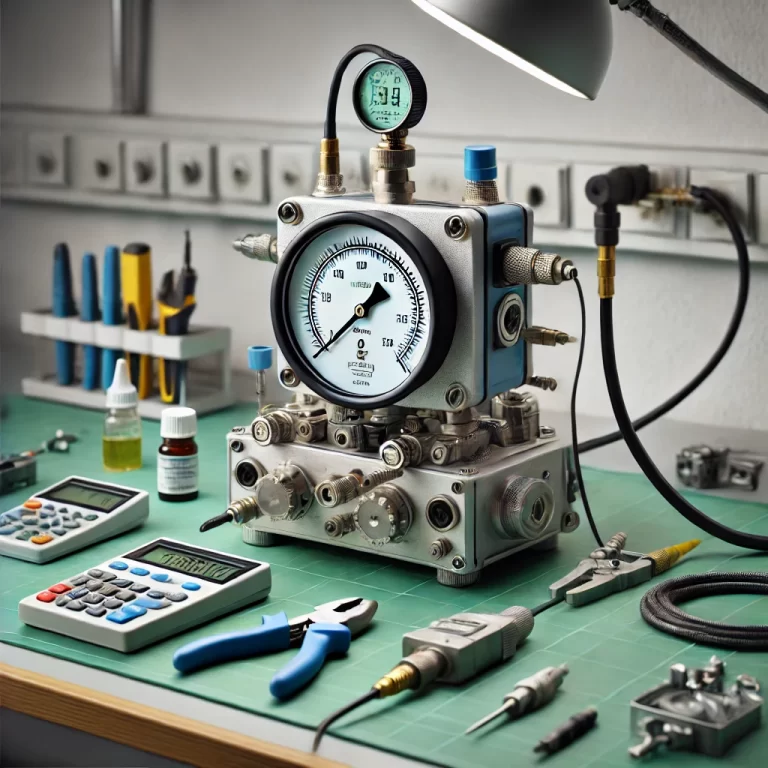

2. Transmitter tightness test

For example, for a pressure transmitter, the transmitter should be steadily pressurized during the tightness test so that the pressure transmitter measurement value reaches the upper limit, the pressure source is turned off, and the transmitter is sealed for 15 minutes.

There should be no leakage. When checking the tightness of a differential pressure transmitter, the high and low pressure ends should be simultaneously introduced with rated pressure for observation.

3. Transmitter insulation resistance detection

Disconnect the transmitter power supply and short-circuit the power terminal and the output terminal. Use an insulation resistance meter to measure the insulation resistance between the power terminal and the ground terminal (housing), the power terminal and the output terminal, and the output terminal and the ground terminal (housing).

When measuring, the reading should be stable for 5s. When the ambient temperature is 15℃~35℃ and the relative humidity is 45℃~75℃, the insulation resistance between each group of transmitter terminals (including the housing) should be no less than 20MΩ.

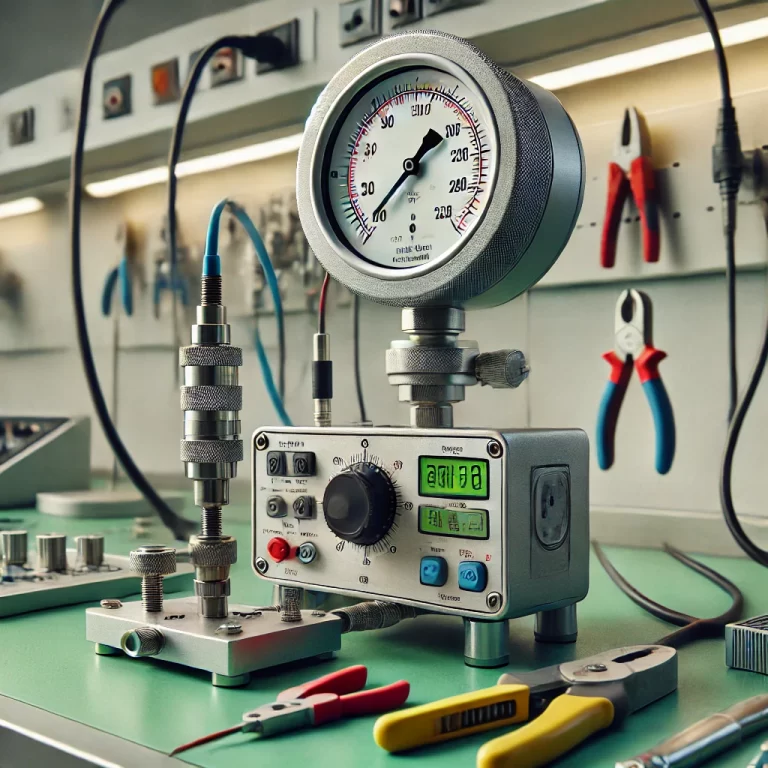

4. Detection of transmitter measurement performance

For example, for a differential pressure transmitter, connect its high and low pressure ends, input the rated working pressure, and measure the output lower limit. Then close the balancing valve to reduce the pressure at the low pressure end so that the pressure difference between the high and low pressure ends reaches the upper limit.

At the same time, measure the output upper limit and calculate the output range (the difference between the output upper and lower limits) under the rated working pressure. Compare it with the output range under the atmospheric pressure and calculate the range change.

Only transmitters that have passed the inspection according to the specification requirements can be issued with an identification certificate and shipped out of the factory.