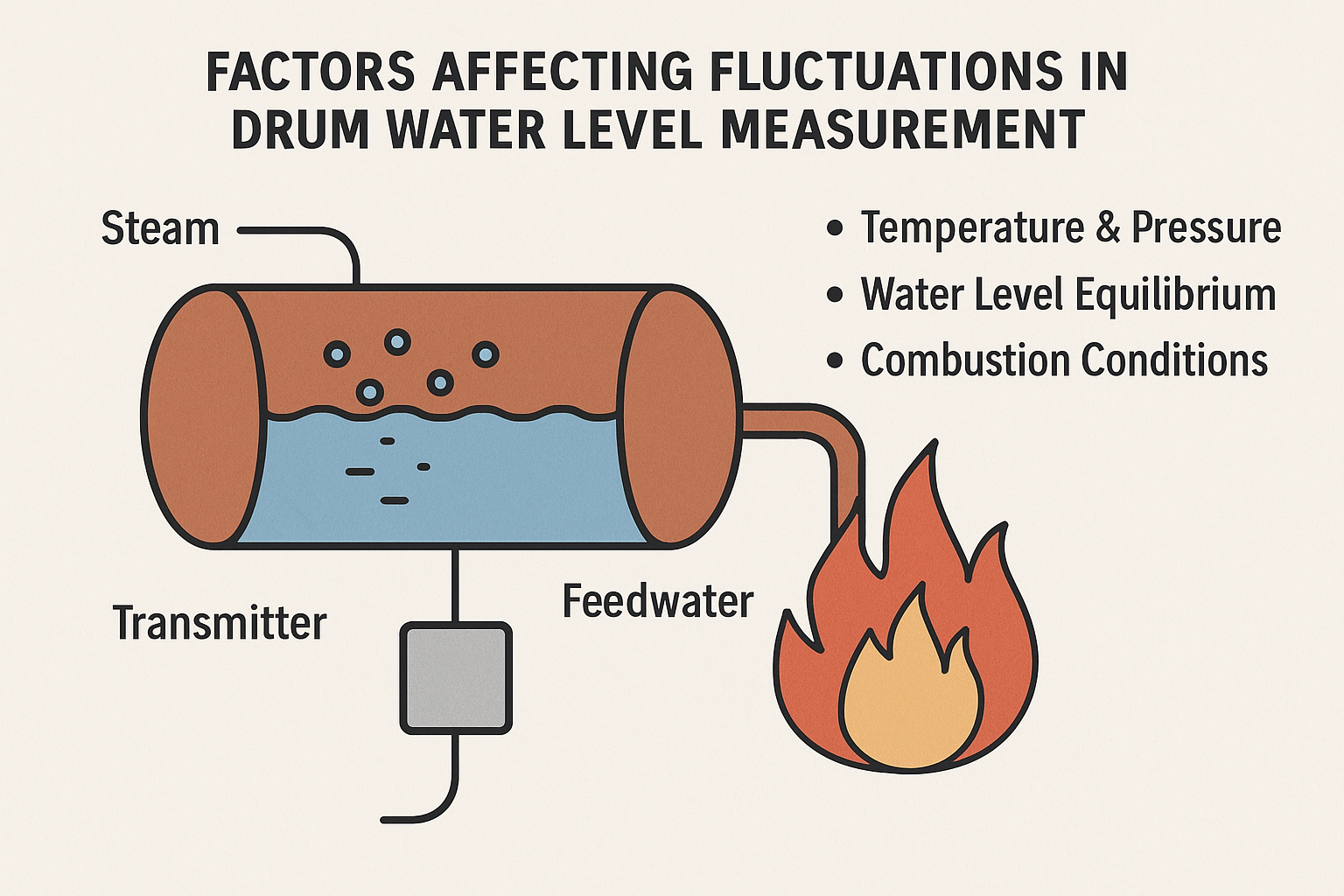

In the operation of thermal power boilers, the steam drum water level is a critical parameter for safety and efficiency. However, the water level measurement often experiences fluctuations due to both actual process dynamics and system-related errors. Understanding the causes of these fluctuations is essential for stable operation and precise control.

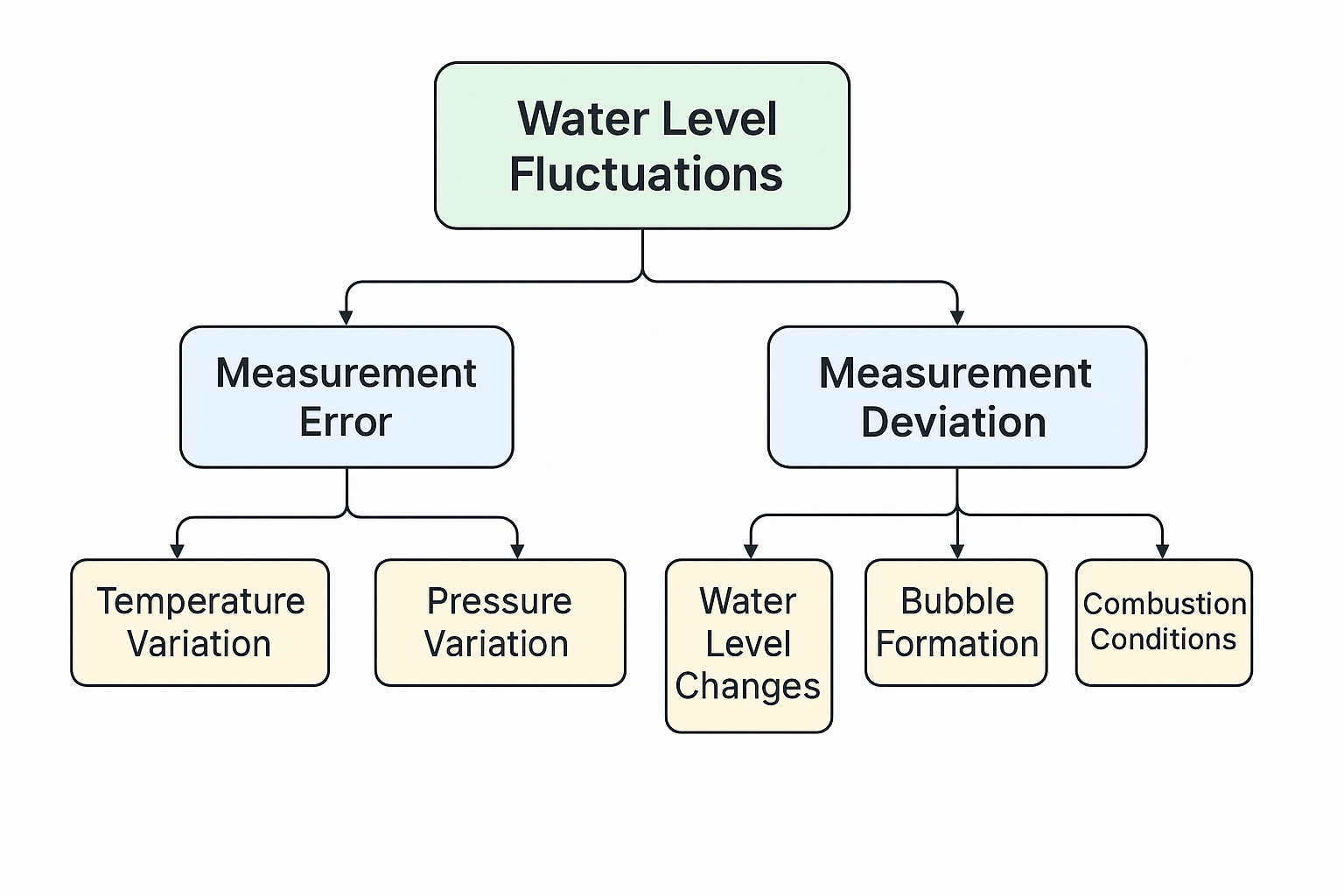

Understanding Measurement Error vs. Measurement Deviation

Before analyzing the causes, it’s important to distinguish between two key concepts:

| Type | Description | Source Location |

|---|---|---|

| Measurement Error | Errors occurring from the sample point to the display system (e.g., DCS). | Instrumentation system, including sensors and transmission. |

| Measurement Deviation | Apparent errors caused by inconsistent physical phenomena within the drum. | Process dynamics inside the steam drum. |

Key Influencing Factors

1. Temperature and Pressure Effects (Measurement Error)

One of the most significant sources of measurement error arises from changes in fluid density caused by temperature and pressure variations.

Although the density variations in the impulse lines may partially offset each other, the density in the high-pressure leg still differs from the actual water in the drum due to:

Temperature changes in the reference leg (filled with water),

Pressure fluctuations inside the steam drum.

Most modern DCS systems have built-in compensation formulas based on live pressure and temperature values. However, the density in the reference leg cannot be measured directly and must be calculated.

🔍 Conclusion: Temperature and pressure fluctuations primarily cause measurement error by influencing density and pressure differential readings.

2. Water Level Balance (Measurement Deviation)

The drum water level is a dynamic equilibrium affected by:

Evaporation rate at the bottom of the drum,

Feedwater replenishment through downcomers,

Bubble content below the water surface.

Factors affecting bubble quantity:

Drum Pressure:

Higher pressure reduces bubble formation, leading to lower transient water level.

Lower pressure increases bubble expansion, causing a sudden rise in water level (similar to opening a soda bottle).

Heat Absorption Rate:

Increased heat input promotes rapid bubble formation.

Sudden changes in load will cause transient water level shifts due to this bubble behavior.

🔍 Conclusion: These are sources of measurement deviation, caused by real physical changes in water volume within the drum.

3. Impact of Combustion Conditions on Water Level Measurement

Combustion conditions directly affect the heat absorption rate, influencing bubble generation and thereby altering transient water levels. Key influencing scenarios include:

Pulverizer Start/Stop: Affects fuel and air supply, shifts flame center, impacts heat absorption symmetry.

Air Flow Dynamics: Uneven primary/secondary air distribution causes flame deflection, resulting in asymmetric heat transfer.

Burner Swing Angles: Change in burner orientation shifts flame center.

Waterwall Slagging: Reduces effective heat absorption on one side of the furnace.

Sootblowing Operations: Sudden removal of deposits may cause abrupt heat absorption imbalance.

Flue Gas Damper Adjustments: Alters gas flow, indirectly affecting water level via heat distribution changes.

💡 These changes often cause:

False water level increases during heat spikes (bubble formation),

Temporary asymmetry between left and right drum level readings,

Control feedback that reduces feedwater when level spikes, creating further complexity.

Summary and Recommendations

| Influence Category | Examples | Impact Type | Control/Compensation |

|---|---|---|---|

| Temperature/Pressure | Reference leg temp/pressure fluctuations | Measurement Error | DCS Compensation |

| Bubble Content Dynamics | Heat absorption, pressure fluctuation | Measurement Deviation | Hard to control |

| Combustion Interference | Pulverizer events, flame shifts | Measurement Deviation | Requires diagnosis |

📌 Best Practices:

Implement reliable temperature/pressure compensation in the DCS.

Monitor burner behavior and air/fuel ratios to minimize heat asymmetry.

Regularly inspect and clean waterwalls to prevent slag-induced imbalance.

Understand that transient water level spikes are not always true volume changes—avoid over-adjusting based on short-term fluctuations.

By distinguishing between true process deviations and system measurement errors, engineers can better diagnose steam drum water level fluctuations and implement more effective control strategies.