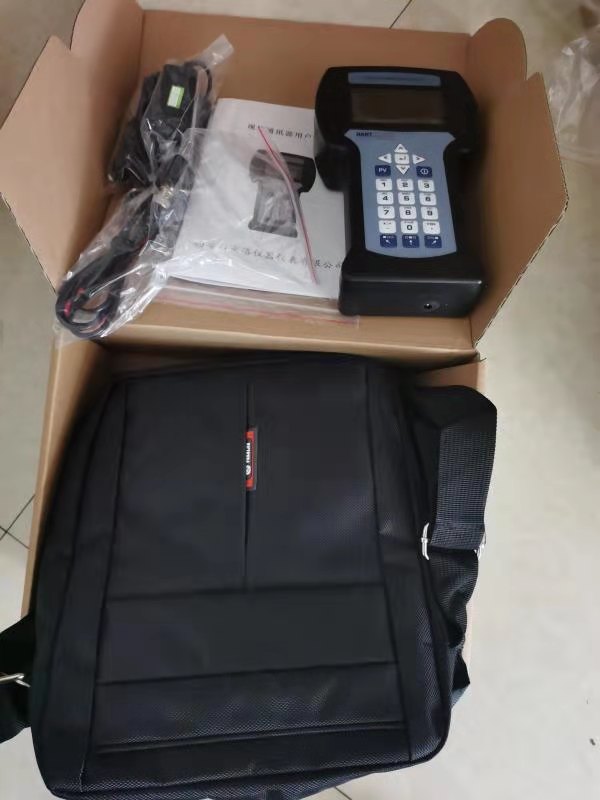

The HART (Highway Addressable Remote Transducer) smart pressure transmitter is a high-precision, high-stability intelligent instrument designed for real-time communication and pressure measurement. It allows users to manage, adjust, and monitor process variables remotely via HART communication, as well as perform on-site configuration using buttons, making it convenient to operate. However, there are several factors that can affect the communication functionality of the HART smart pressure transmitter during operation.

1. Low Power Supply Voltage

A common issue encountered when using HART smart pressure transmitters is the lack of communication, output errors, or flickering display on the transmitter’s indicator. This typically occurs when the power supply voltage is too low to support proper functioning. Insufficient voltage can prevent the transmitter from communicating properly and cause incorrect or erratic output readings.

Solution:

To resolve this issue, ensure the power supply provides the appropriate voltage within the transmitter’s specified range. Replacing or adjusting the power source should restore proper communication and output.

2. Excessive Cable Length

When communication issues arise, and the voltage at the measuring terminals is normal, one possible cause could be the length of the cable connecting the transmitter to the control system. If the cable is too long, it can lead to significant distortion in the communication waveform, which can disrupt or completely prevent proper communication.

Solution:

To minimize this issue, use cross-linked (XLPE) cables and shorten the length of the cable used for the transmitter connection. Shortening the cable helps maintain signal integrity and ensures reliable communication.

3. Electromagnetic Interference (EMI)

Electromagnetic interference is another common cause of communication problems with HART smart pressure transmitters. Despite proper power supply, cable lengths, and wiring, electromagnetic interference can lead to malfunctions such as inaccurate readings or complete failure to communicate. This is often seen in industrial environments where various electrical equipment generates high-frequency electromagnetic fields.

Solution:

To reduce electromagnetic interference, several strategies can be employed:

- Twisted and Shielded Cables: Use twisted-pair cables to help cancel out electromagnetic noise. Additionally, shielded cables with proper grounding can further protect the signal from external interference.

- Distance and Layout: Increase the distance between the instrument’s signal wires and any power cables or sources of interference. When possible, avoid laying power and signal cables parallel to each other, as this can introduce more noise into the system.

- Magnetic Shielding: For particularly noisy environments, shielding the cables or equipment with magnetic shielding can help reduce the impact of EMI.

Conclusion

In summary, several factors can disrupt the communication of HART smart pressure transmitters, including low power supply voltage, excessive cable lengths, and electromagnetic interference. Ensuring that the power supply is within the correct voltage range, using appropriate cable lengths, and implementing effective shielding and grounding practices can significantly enhance the reliability of communication. By addressing these common issues, users can maximize the performance and accuracy of their HART smart pressure transmitters in the field.