In many industrial accidents, the root cause isn’t the equipment itself — it’s a lack of gas detection knowledge.

A worker enters a confined space without checking oxygen concentration and passes out due to hypoxia.

A chemical plant’s gas alarm goes off by mistake — because the operator confused “PPM” with “mg/m³”.

These are not rare mistakes. They are common and dangerous.

Understanding the difference between explosion limit, alarm threshold, and gas concentration units is essential for every safety engineer and field operator. This article reveals the three biggest traps in combustible gas detection — and how to avoid them.

1. Understanding Gas Concentration Units — Don’t Mix Them Up!

Misunderstanding gas concentration units is one of the most frequent causes of false alarms or failed warnings.

Let’s clarify the four most common units and their correct usage.

1. %LEL — Explosion Risk Indicator

Full name: Lower Explosive Limit (percentage)

Meaning: Used to indicate the explosion risk of flammable gases.

For example, methane has an explosion limit of 5%VOL.

So, 100%LEL = 5%VOL (if methane reaches this level, any spark can trigger an explosion).Alarm settings:

First-level alarm ≤ 25%LEL (warning)

Second-level alarm ≤ 50%LEL (emergency — shut down gas and start ventilation)

2. %VOL — Volume Percentage

Used for: Oxygen (O₂), Carbon dioxide (CO₂), Nitrogen (N₂), etc.

Meaning: Shows how much of a gas is present in the air.

Normal oxygen = 21%VOL

Below 19.5% → oxygen deficiency

Above 23.5% → supports combustion and increases fire risk

3. PPM — Trace Detection Unit

Full name: Parts Per Million

Meaning: For very low concentrations of toxic gases, such as CO or H₂S.

Even 50–100 PPM can be deadly.Conversion rule:

1%VOL = 10,000 PPM

Example: 2%VOL = 20,000 PPM; 500 PPM = 0.05%VOL

4. mg/m³ — Mass Concentration Unit

Used by: Environmental monitoring agencies.

Conversion formula (standard conditions, 25°C, 1 atm):

mg/m3≈(Molecular weight×PPM)/24.45For CO (molecular weight = 28):

50 PPM ≈ 57.2 mg/m³Example trap:

The occupational exposure limit (OEL) of CO is 20 mg/m³ ≈ 17 PPM.

If the alarm is set to 20 PPM while the device uses mg/m³, the detector won’t trigger until it’s already unsafe!

⚠️ Key takeaway: Unit confusion = silent danger. Always verify which unit your gas detector uses.

2. The Four-in-One Gas Detector — The First Line of Safety

In confined spaces such as tanks, wells, or fermentation pits, a four-in-one gas detector is your life-saving tool.

It measures four essential gases simultaneously:

1. Oxygen (O₂)

Safe range: 19.5%–23.5%VOL

<19.5% → suffocation risk

23.5% → high fire risk

2. Combustible gases (%LEL)

Measures explosion risk for methane, propane, etc.

100%LEL means the gas has reached its lower explosion limit — ignition will cause an explosion.

Set alarms: 25%LEL (level 1), 50%LEL (level 2)

3. Hydrogen sulfide (H₂S)

Rotten egg smell; extremely toxic.

Exposure above 100 PPM can cause instant collapse or death.

4. Carbon monoxide (CO)

Colorless, odorless, lethal.

Produced by incomplete combustion.

200 PPM → unconsciousness; higher → death.

Detection Procedure: “Ventilate → Detect → Work”

Ventilate first using an explosion-proof blower (never pure oxygen!).

Test in order: O₂ → Combustible → H₂S → CO.

Open areas: gas sensors ≤10 m from release source (flammable), ≤4 m (toxic).

Confined areas: ≤5 m (flammable), ≤2 m (toxic).

Start work only if readings are safe.

Wear the detector near the breathing zone (chest level) and leave immediately when alarm triggers.

Alarm and Interlock Logic

Combustible gas:

Level 1 (≤25%LEL): check site conditions

Level 2 (≤50%LEL): automatically cut gas supply and activate exhaust fans

Oxygen:

<19.5% or >23.5% → stop work, ventilate

Toxic gases:

Level 1: ≤100% OEL

Level 2: ≤200% OEL

(e.g., for CO: OEL = 17 PPM → alarms at 17 and 34 PPM)

According to GB/T 50493-2019:

Level 1 alarm ≤100% OEL

Level 2 alarm ≤200% OEL

If range is limited, use ≤5% IDLH (Immediately Dangerous to Life or Health)

Regular calibration is crucial — at least once every 6–12 months.

Sensors typically last 1–2 years and must be replaced to maintain accuracy.

3. Combustible Gas Categories — Knowing the Enemy

Not all gases are equally dangerous.

Understanding explosion limits and density helps you detect and prevent risks accurately.

(1) By Explosion Risk

Class I (Extremely flammable, LEL ≤10%)

Methane (5–15%)

Hydrogen (4–75%)

Acetylene (1.5–82%) → extremely explosive

Class II (Moderate, LEL >10%)

Ammonia (15–28%)

Carbon monoxide (12.5–74%)

(2) By Density (Heavier or Lighter Than Air)

Heavier gases (Propane, LPG) → sink into low areas → measure near the floor.

Lighter gases (Methane, Hydrogen) → rise upward → measure near ceilings or vents.

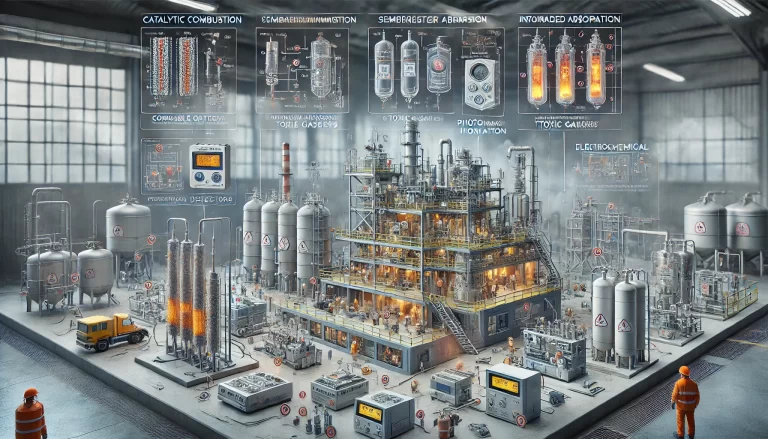

(3) Detection Technologies

| Sensor Type | Suitable for | Notes |

|---|---|---|

| Catalytic combustion | Hydrocarbons (CH₄, C₃H₈) | Needs oxygen; less accurate in low-O₂ areas |

| Infrared (NDIR) | CH₄, CO₂ | High stability, ideal for closed spaces |

| Electrochemical | CO, H₂S | Fast response; beware of cross-interference |

(4) Safety Measures

Add odorants (like tetrahydrothiophene) to natural gas for early leak detection.

Use explosion-proof equipment (IP68-rated).

Never perform hot work in flammable zones without testing (<25%LEL).

Regularly calibrate alarms with standard test gas (e.g., 50%LEL methane).

Conclusion: Gas Detection Is a Lifeline, Not a Formality

Gas detection is not just a routine check — it’s a life-saving barrier.

Remember these three principles:

✅ Understand and correctly apply %LEL, %VOL, PPM, and mg/m³.

✅ Always follow the “Ventilate → Detect → Work” sequence.

✅ Know your gases and their explosion limits to set the right alarms.

Each proper calibration, each correct reading, is another step toward saving lives.