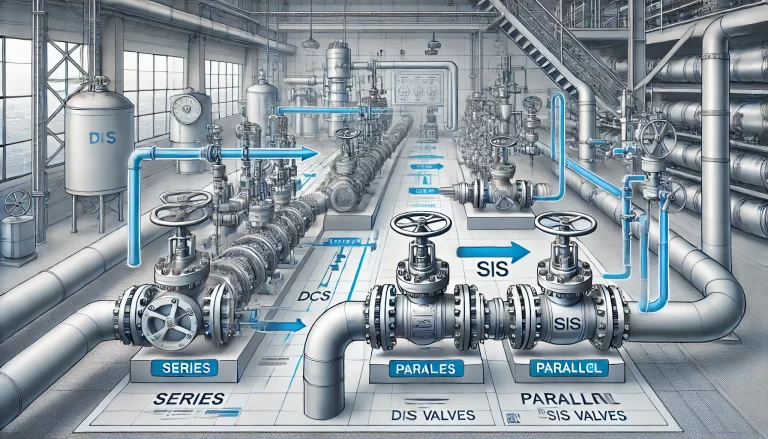

In process industries, Distributed Control System (DCS) valves and Safety Instrumented System (SIS) valves play critical roles in process control and safety, respectively. When designing these systems, engineers must decide whether to install these valves in series or parallel. Each configuration has its advantages and challenges that impact the system’s overall safety, reliability, and maintainability. Here’s an in-depth exploration of both configurations.

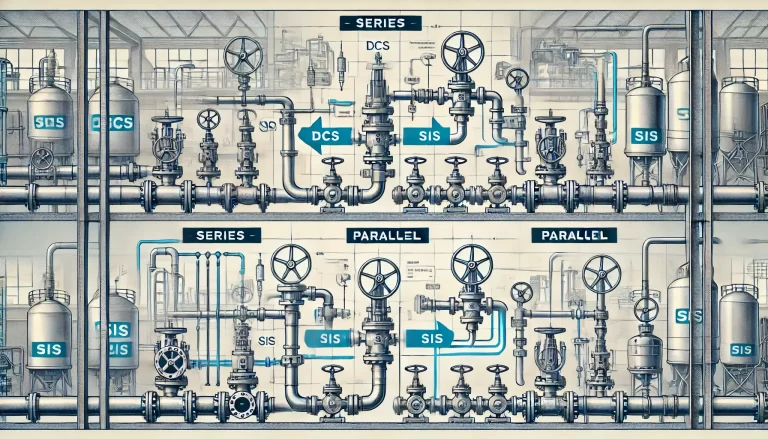

1. Series Installation

A series installation positions the DCS and SIS valves sequentially in the same pipeline. This means that the process media flows through the DCS valve first and then the SIS valve. This configuration is often favored for systems where safety is paramount and provides a layered approach to ensure system reliability.

Advantages of Series Installation

Enhanced Safety through Redundancy

- In a series configuration, both valves work in tandem to protect the system. The DCS valve manages normal process control functions like regulating flow and pressure. The SIS valve, typically a fail-safe device, acts as a last-resort safeguard that closes only in emergencies. If the DCS valve fails or malfunctions, the SIS valve still provides an additional layer of protection, ensuring that the system can shut down safely if needed.

2. Simplified Control Logic

- Since the media must pass through both valves sequentially, the control logic is generally more straightforward. The DCS valve is responsible for normal control, while the SIS valve is programmed to act only in emergencies. This arrangement simplifies the fault diagnosis process and helps operators and engineers understand and manage the valve operations with minimal complexity.

3. Reduced Risk of SIS Valve Overuse

- SIS valves are often designed to remain in a fixed position (usually closed) and only actuate in emergency conditions. By using a series setup, the SIS valve is only actuated when absolutely necessary, preventing wear from frequent operation and reducing the risk of inadvertent actuation. This setup prolongs the lifespan of the SIS valve, which is especially important in critical safety applications.

Disadvantages of Series Installation

Increased Pressure Drop

- With two valves in series, the system experiences a higher cumulative pressure drop. This can be a drawback for processes that are sensitive to pressure changes, especially when working with high-viscosity fluids or long pipeline systems. It may necessitate additional design considerations, such as more robust pumping systems, to compensate for the pressure loss.

Higher Installation and Maintenance Costs

- A series installation requires extra space to accommodate both valves. In facilities where space is limited, this can complicate design and installation, potentially increasing overall costs. Additionally, routine maintenance becomes more complex as technicians need to access both valves sequentially, potentially increasing downtime.

2. Parallel Installation

Parallel installation means that the DCS and SIS valves are set up on separate branches of the pipeline. Each valve independently manages a specific part of the system, allowing media to flow through either the DCS valve branch for regular control or the SIS valve branch for emergency shut-off.

Advantages of Parallel Installation

Greater Operational Flexibility

- With parallel installation, the DCS valve and SIS valve function independently, giving operators greater control over different operational states. The DCS valve can regulate process flow under normal conditions, while the SIS valve provides an emergency shutdown path without interfering with the main process line. This arrangement is beneficial for systems that require frequent changes in operating conditions.

2. Reduced Impact of Valve Failures

- In a parallel setup, a malfunction of one valve (e.g., the DCS valve) does not necessarily interrupt the entire system’s operation, as the other valve can still provide a pathway or safeguard. This isolation of control paths enhances system resilience and helps maintain operational continuity even when one valve requires maintenance or experiences a failure.

3. Easier Maintenance and Accessibility

- Since each valve is located on a separate branch, technicians can perform maintenance on one valve without interrupting the process flow on the other branch. This arrangement can reduce downtime and increase overall system availability, which is advantageous for facilities that require continuous operation.

Disadvantages of Parallel Installation

Increased Complexity in Control Logic

- The independence of the two branches introduces more complexity into the control logic. Both branches need to be carefully synchronized to ensure that the system does not allow media to flow inappropriately or become stuck in an unsafe state. This complexity can increase the likelihood of configuration errors and requires more robust testing and validation during design and commissioning.

Potential Reduction in Safety Integrity

- In a parallel configuration, if one valve fails to actuate (e.g., the SIS valve fails to close during an emergency), the system may face compromised safety. This configuration requires high reliability in the individual valves and the overall control system to detect failures and respond appropriately. In critical applications, extra sensors and fail-safe logic may be required to compensate for this potential limitation.

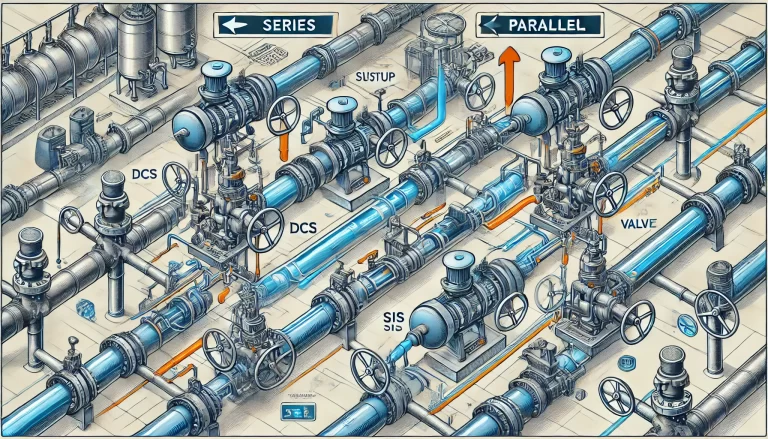

3. Summary and Application Recommendations

Selecting between a series and parallel configuration for DCS and SIS valves requires careful consideration of the specific process requirements, safety standards, and operational constraints. Below are some general guidelines to help determine the appropriate setup:

Series Installation: Best suited for applications where safety is paramount and simplicity in control logic is desired. It provides an added layer of protection, with both valves working together to prevent undesired flow during emergency shutdowns. Industries like oil and gas, petrochemicals, and certain chemical processing plants may favor this setup for its enhanced safety and redundancy benefits.

Parallel Installation: Ideal for systems that require flexibility and continuity of operations, even during valve maintenance or partial system failures. It is particularly suited for complex processes with multiple operating states and for facilities requiring high uptime. This configuration is often used in industries like power generation or water treatment, where operational flexibility is critical.

In conclusion, each configuration has its strengths and potential drawbacks. Series installation is typically favored for simplicity and redundancy, especially in systems where safety is critical. In contrast, parallel installation offers operational flexibility and easier maintenance but requires careful control logic design and may involve additional safety considerations. The final choice should always align with the plant’s overall safety, operational requirements, and maintenance practices.