Do you need to measure the flow of liquids in your business but don’t know where to start? Do you need reliable flow measurements done regularly? If you answered yes to either of these questions, then you need to consider using an electromagnetic flow meter.

An electromagnetic flow meter, also known as mag meter, is a device that uses Faraday’s law of induction to know the flow rate of the electrically conductive water body. This type of flow meter is useful? Electromagnetic flowmeters may be the perfect solution for you! This blog post will discuss everything you need to know about electromagnetic flow meters.

It is important to note that several types of electromagnetic meters are available in the market today. They are used to measure linear, non-linear, volumetric flow, and the mass flow of fluid flowing through a channel but choosing the one right for you is another ball game entirely.

You must first be equipped with knowledge about this measuring instrument, and we will be helping by covering topics on how the electromagnetic flowmeters work, the different types available, and some of their common advantages.

By the end of this post, you should have a good understanding of whether this flow measurement is the right choice for you.

What is an Electromagnetic Flow Meter?

The electromagnetic flow meters or magnetic or volumetric flow meters are instruments that have the ability to measure circulation rates of heterogeneous solutions, like dirty liquids, oil and water mixture, water-based liquids like raw material water, wastewater, water from reservoirs, liquids containing waste fluids, and/or intake water with a lot of dirt or garbage in it.

Electromagnetic flow meters are devices used to measure flow, liquid velocity, and the rate of water moving through induced voltage. It is a flow meter with no moving parts or obstructions.

Fluids require different metering systems because they come in different properties. These mag meters are one of the most conventional measuring instruments available for measuring circulation rates because they use electromagnetic induction.

How Do Electromagnetic Flow Meters Work in Magnetic Field?

According to Faraday’s Law (Law of Electromagnetic Induction), the rate of conductive liquid passing through a pipeline is measured with electromagnetic flow meters with sensors. The magnetic field produces electrical signals in the conductor.

When material and magnetic field move in relative to each other, voltage is created. An electromotive force gives way for the electromagnetic induction produced through the electrical conductor in the magnetic field.

Simply put, electromagnetic meters work by using an electromagnetic field to measure the velocity of a liquid passing through a channel. This information is then used to calculate the flow rate of the liquid.

Faraday’s law proves that the fluid’s pressure is directly proportional to the voltage generated through the liquid’s flow. This simply means that the voltage generated will increase (increased induced voltage) when the flow rate/pressure of the fluid flow increases.

Application of Electromagnetic Flow Meters

The magnetic flow meter has an extensive range of applications, as they are used in the oil and gas sector, textile industry, mining and metallurgy industry, water supply, drainage and sewage treatment, wastewater solutions, chemical, paper, and sugar industry.

The Active and Passive Mag Meters

The active and passive mag meters are two main electromagnetic flow meters based on how flow meters are powered.

The Active Meter

The active meters are powered by a flow meter connected to an active output, i.e., the flow meter is internally powered to an output (transmitter).

The Passive Meter

Passive meters require the flow meter to be externally powered through a local display. The device model number is used to determine whether the output is active or passive.

Liquid Conductivity and Flow Measurement

As customers, your choice for quality electromagnetic meters will revolve around it working at high accuracy and conductivity and is not influenced by dirty liquids with high levels of suspended solids.

The mag meters work best with fluids that contain a certain conductivity, meaning the fluid is not greatly affected by dirt or garbage in it. The higher the content of these materials, the lower the accuracy of most flow meters. However, for electromagnetic flow meters, this is not as much cost-effective.

The accuracy and conductivity of the magnetic flow meter are highly dependent on the dimension of the pipe and not the size of the magnetic flow meter. Why? Because accuracy is based on the minimum flow velocity and a maximum flow rate, both determined by the pipe’s measurement but at the right temperature.

The size of the meter is not as important as meeting the minimum and maximum flow rates in order for it to be effective. So, if you have a dirty liquid with high levels of suspended solids, an electromagnetic flow meter would still be your best bet!

The Accuracy of Magnetic Flow Meter

The lack of moving parts (sensor parts) in the mag meter is a factor that decreases excessive pressure drop when a flow meter is installed.

A magnetic flow meter is suitable as long as the liquid being measured has a conductivity above 20 micro Siemens, a temperature of not more than 160 degrees Celsius with extreme acidity, is corrosive and abrasive

the circulation rate of seawater and food-grade materials (stainless steel SUS316 and Teflon) can be estimated with a magnetic meter.

Types of Electromagnetic Flow Meter

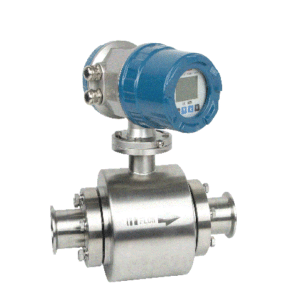

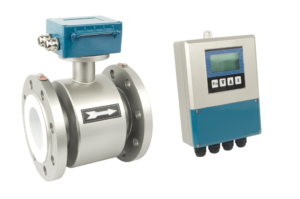

In-Line Model Magnetic Flow Meter

The In-Line Model is a sensor that generates a magnetic field in an electrode-like form. Electrodes are installed on opposite sides of the pipe and reinforced with electric coils.

It got the name “In-Line” because a flange or thread is installed in it during installation, during installation, and the meter is directly welded to the pipe. It can measure the accuracy of up to 0.2%

Insertion Model Magnetic Flow Meter

On the other hand, the insertion Model is installed by inserting electric coils into the pipe and an electrode at the end of the pipe, which measures the flow rate of the fluid. The pipe is perforated, and a magnetic sensor is fitted into the perforated hole.

This type of mag meter is best suited for medium to high pipe sizes and is more cost-effective when used on large pipe sizes. It has an accuracy level of 1 to 2%, and the very goal of using this type of mag meter is to reduce installation cost and time.

Faraday’s law proves that the insertion mag meter relies on electric induction due to current-voltage; this is the same for the in-line mag meter. They cannot be used to read particles with low or no conductivity.

The Advantages of Mag Meters

- The flow rate of suspended liquid-solid two-phase flow, corrosive flow, and sloping medium can be measured with electromagnetic meters because they have no obstructive flow component, although it has to be calibrated by water to measure other conductive liquids;

- Reliability is a key factor when choosing a mag meter; It is simpler to operate and install, and it functions under low power consumption; It is not susceptible to additional pressure loss because of its lack of moving parts;

- It can measure the flow rate of conductive liquids in both forward and reverse directions;

- This volume flow measuring instrument is not affected by viscosity, density, and temperature of the medium and the fluid to be measured;

- Under symmetric distribution, the electromagnetic flowmeter is not dependent on the laminar or turbulent state, and it has a range as wide as 100:1.

Disadvantages of the Mag Meter

- The magnetic flow meters cannot be used in measuring liquids with a large amount of gas and other gases;

- Magnetic flow meters cannot measure fluids with low or no conductivity like organic solvents or petroleum products;

- It cannot measure a medium with a high temperature.