1. Arrival Inspection

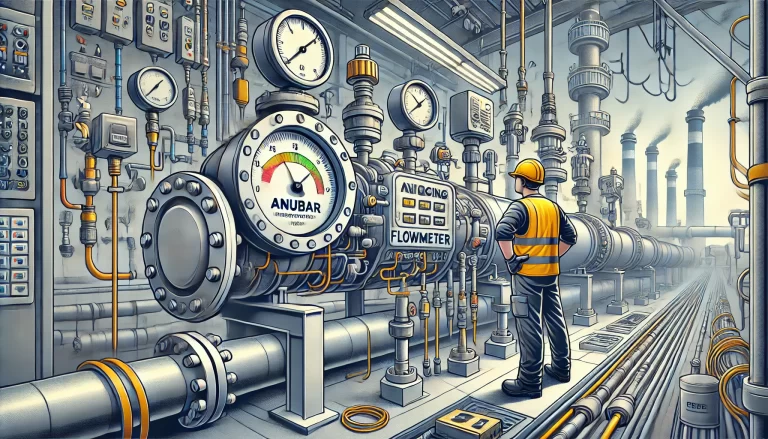

Quantity and Specification Verification: Carefully verify that the quantity, model, and specifications of the equipment match the procurement contract and design requirements.

Visual Inspection: Inspect the equipment for any physical damage, deformation, corrosion, or other visible defects. Document and photograph any discrepancies.

Nameplate Verification: Check the equipment nameplate for accurate information, including manufacturer, production date, serial number, and compliance certifications.

Packaging Check: Assess the integrity of the packaging. Any damage during transportation must be recorded and reported immediately.

2. Documentation Collection

Mandatory Documents: Collect and verify the completeness of essential documents such as operation manuals, certificates of conformity, quality inspection reports, calibration certificates, and safety instructions.

Supporting Documents: Ensure the preservation of packaging lists, transportation documents, and purchase agreements for future reference.

Digital Archiving: Scan and store all critical documents in an organized digital archive to facilitate traceability and easy access.

3. Storage and Inventory Management

Storage Conditions: Assign suitable storage locations based on equipment characteristics, ensuring dry, well-ventilated, and temperature-controlled environments. Implement protective measures to prevent damage.

Categorized Storage: Classify equipment by type and usage, apply proper labeling, and update inventory records accordingly.

Security Measures: Implement security protocols to prevent unauthorized access or handling of high-value or sensitive equipment.

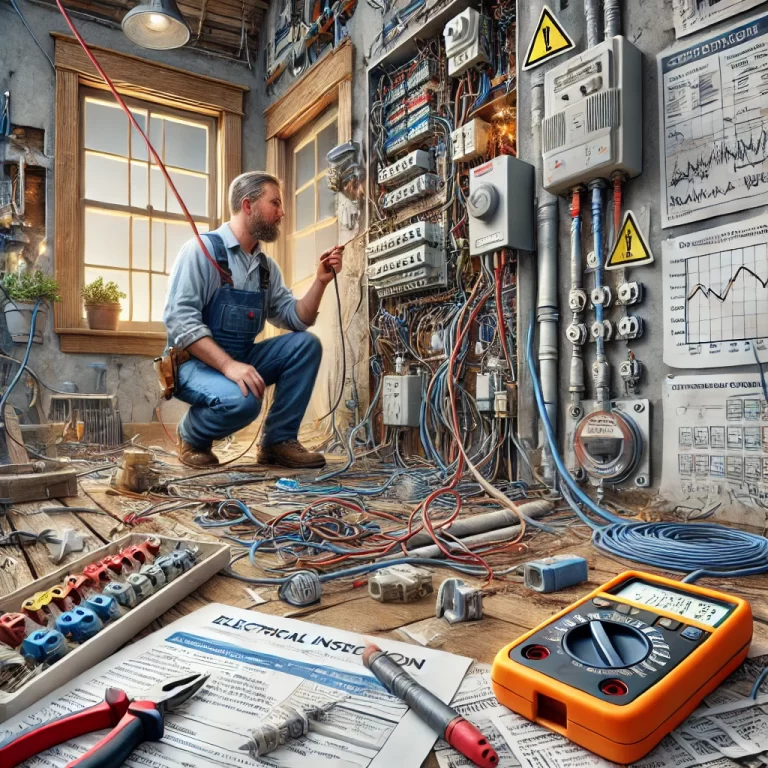

4. Equipment Inspection and Calibration

Calibration: For instruments requiring calibration, perform calibration according to the specified cycle and standards before use. Maintain calibration logs for future audits.

Functional Testing: Conduct comprehensive functionality and performance tests to ensure the equipment meets all technical requirements.

Third-Party Verification: Engage accredited third-party organizations for critical equipment testing when necessary.

5. Equipment Ledger Establishment

Detailed Recordkeeping: Create and maintain an equipment ledger detailing name, model, specification, serial number, storage/installation location, calibration dates, inspection results, and responsible personnel.

Tracking and Traceability: Implement a tracking system (e.g., barcodes or RFID) for real-time status updates and traceability.

6. Coordination with Project Schedule

Timely Utilization: Align equipment usage and installation with the project timeline to avoid delays and ensure efficient resource allocation.

Advance Planning: Coordinate with construction and installation teams to plan equipment deployment in line with project progress.

7. Issue Resolution and Communication

Defect Handling: Promptly report and document any equipment defects, shortages, or specification mismatches. Notify suppliers immediately and collaborate on corrective actions.

Dispute Resolution: Establish a clear process for dispute handling, including escalation procedures and timelines for issue resolution.

Continuous Feedback: Encourage regular feedback from installation teams and end-users to improve future procurement and acceptance processes.

8. Responsibility Assignment and Sign-off Process

Defined Responsibilities: Clearly define the responsibilities of each team member involved in the inspection and acceptance process.

Sign-off Protocol: Implement a formal sign-off procedure at each critical stage, ensuring accountability and traceability.

By implementing this comprehensive procedure, the organization can ensure that all incoming equipment meets quality, safety, and operational standards, contributing to project success and long-term asset reliability.