Environmental sustainability and occupational safety are inseparable elements of modern process industries. Instrumentation plays a critical role in monitoring hazardous substances, controlling emissions, and ensuring compliance with environmental regulations. The following guidelines summarize best practices for instrumentation in environmentally sensitive applications.

1. Combustible and Toxic Gas Detection

1.1 Fixed Gas Detection

In locations where combustible or toxic gases may leak or accumulate, as well as at fresh air inlets of buildings, combustible and toxic gas transmitters must be installed.

Signals should be wired to a dedicated Gas Detection System (GDS) via AI (Analog Input) cards or racks.

The central control room should include an independent GDS operator workstation with real-time display and dedicated audiovisual alarm devices.

1.2 Portable Gas Detection

Based on the facility’s characteristics, portable multi-gas detectors (typically four-in-one units capable of monitoring oxygen, combustible gases, and two selected toxic gases) should be provided for field personnel. These enhance personal safety during maintenance, confined space entry, or emergency operations.

2. Toxic Substances

2.1 Sealed Instrumentation

For high-toxicity media, diaphragm-sealed instruments and bellows-sealed valves should be employed. This prevents leakage of hazardous process fluids and minimizes environmental and personnel exposure risks.

3. Noise Hazards

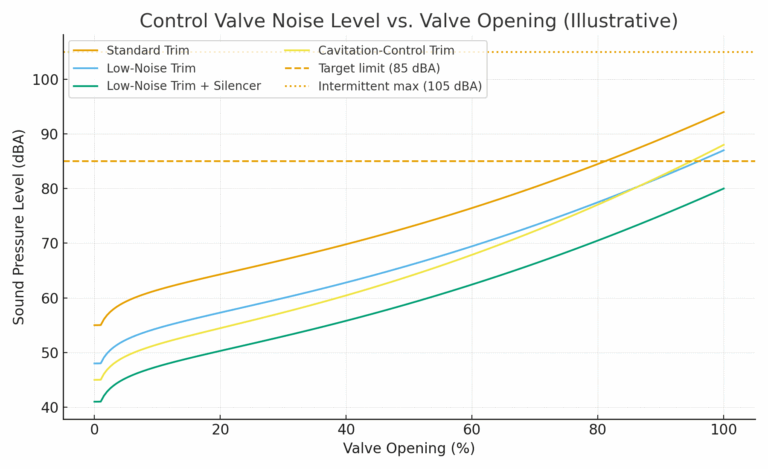

The noise level of control valves should be controlled below 85 dBA under normal operation.

For intermittent valves, the permissible limit is 105 dBA.

Engineering controls such as low-noise trim, silencers, and insulation should be considered to meet occupational safety standards.

4. Radiation Safety

4.1 Radioactive Instruments

Instruments containing radioactive sources (e.g., certain density or level gauges) must carry prominent hazard signage and comply with national standards (GBZ 114–2002 / GBZ 125–2002).

Continuous monitoring via CCTV systems is recommended.

The use of radioactive instruments should be minimized where alternative measurement technologies (e.g., ultrasonic or radar) are feasible.

5. Wastewater Monitoring

Effluent streams must be continuously monitored using appropriate analyzers (COD, ammonia, pH, conductivity, etc.) to ensure compliance with discharge permits.

Instrumentation provides real-time feedback to protect the environment and verify that treated wastewater meets national and local regulatory standards.

6. Flare Emissions

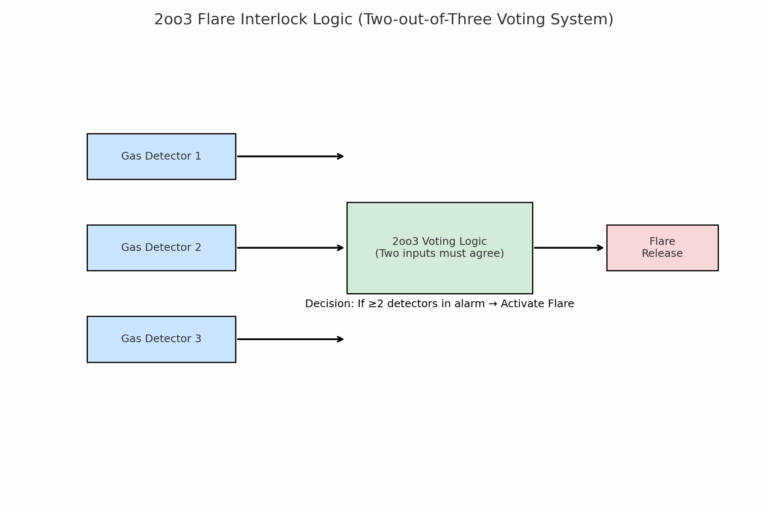

Flare systems should incorporate two-out-of-three (2oo3) voting interlocks to minimize unnecessary releases. This approach ensures reliability while preventing avoidable flaring, reducing both greenhouse gas emissions and visible pollution.

7. Furnace and Stack Emissions

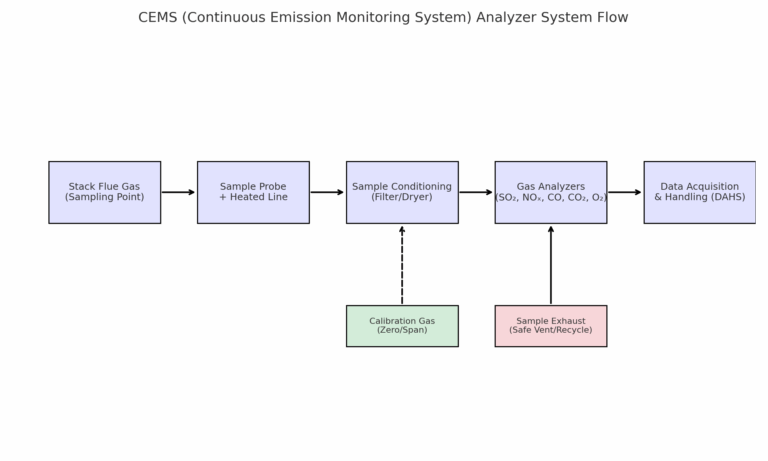

Furnace areas must be equipped with Continuous Emission Monitoring Systems (CEMS) to measure SO₂, NOₓ, CO, CO₂, O₂, and particulate matter.

Chromatographs and other process analyzers should include sample gas recovery systems to reduce vented emissions and protect the environment.

8. Analyzer House Venting

Analyzer shelters should be fitted with collection manifolds to capture and safely discharge sample gases, thereby reducing direct atmospheric emissions. Proper design includes vent routing to safe locations with dilution or scrubbing.

9. Radioactive Materials Management

The transport, storage, and installation of radioactive instruments must strictly follow national regulatory standards. Whenever possible, alternative technologies should be prioritized to avoid the use of radioactive sources, aligning with global trends toward safer, more sustainable instrumentation.

Conclusion

Environmental protection requirements are increasingly stringent across the industrial sector. Proper selection and configuration of instrumentation—ranging from gas detection systems and sealed instruments to emission monitoring analyzers—form the backbone of compliance and sustainable operations. By integrating these measures, plants not only safeguard human health and the environment but also ensure long-term operational reliability and regulatory adherence.