1. Installation Location Selection

Choosing the appropriate installation location is crucial for ensuring the accuracy, stability, and longevity of temperature transmitters. Poor placement can lead to measurement errors, shortened lifespan, or even equipment failure. Below are key considerations:

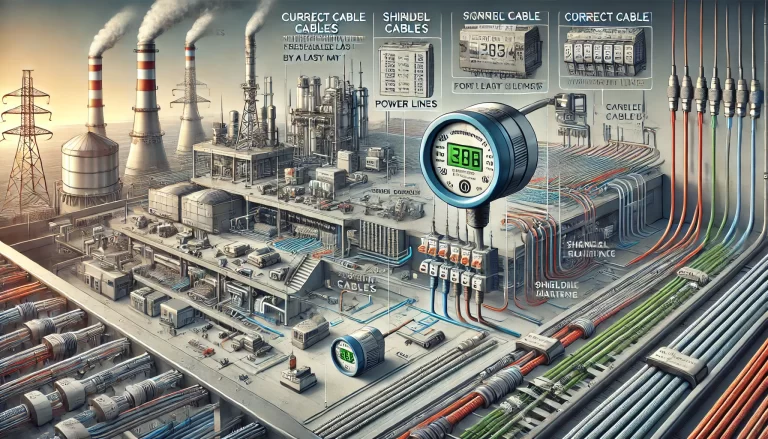

1.1 Avoid Electromagnetic Interference (EMI)

Temperature transmitters should be installed away from strong electromagnetic interference (EMI) sources such as large motors, transformers, and variable frequency drives (VFDs). These sources generate electromagnetic fields that can cause signal distortion or malfunction of the transmitter.

Best Practice: Maintain a minimum distance of 1 meter from EMI sources.

Example: A factory reported frequent erratic readings from a temperature transmitter installed near a high-power transformer. After relocating the transmitter 1.5 meters away and using a shielded cable, signal accuracy significantly improved.

1.2 Avoid High-Temperature Environments

Installing a temperature transmitter near high-temperature equipment such as boilers, furnaces, or heat exchangers can impact performance and reduce the device’s lifespan.

Best Practice: Keep a minimum distance of 1.5 meters from heat sources. If unavoidable, install thermal shields or heat-resistant enclosures.

Industry Standard: Follow IEC 60584-3 for temperature sensor installation in high-temperature environments.

1.3 Ensure Proper Ventilation

Poor ventilation can cause temperature transmitters to overheat, leading to performance degradation.

Best Practice: Install the transmitter in a well-ventilated area. If mounted inside an enclosure, ensure it has ventilation holes or an exhaust fan.

Case Study: A food processing plant faced issues with overheating transmitters inside a control cabinet. Installing a small cooling fan reduced the temperature by 10°C, stabilizing readings.

1.4 Prevent Vibration Damage

Excessive vibration from compressors, vibrating screens, or piping can loosen connections and damage internal components.

Best Practice: Use anti-vibration mounts, rubber shock absorbers, or install the transmitter on a vibration-isolated platform.

Case Study: A chemical plant had transmitters mounted on vibrating pipelines. Using flexible mounting brackets and damping pads reduced signal noise and extended equipment lifespan.

2. Protection Measures

To ensure the long-term reliability of temperature transmitters, various protection measures should be implemented based on the installation environment.

2.1 Waterproof and Moisture Protection

Moisture ingress can lead to short circuits, corrosion, and insulation failure, especially in outdoor or high-humidity environments.

Best Practice:

Use IP65 or IP67-rated enclosures for outdoor installations.

Apply waterproof sealant at cable entry points.

Conduct periodic inspections of sealing gaskets and replace damaged ones.

Industry Standard: Follow IEC 60529 for ingress protection ratings.

2.2 Dust and Corrosion Resistance

Dust accumulation can obstruct heat dissipation, and corrosive gases can degrade metal components.

Best Practice:

Use dust-proof covers in cement plants and dusty environments.

For corrosive environments (e.g., chemical plants), use stainless steel enclosures or special coatings.

Perform regular cleaning of sensors and housings.

Example: A chemical facility installed corrosion-resistant enclosures and reduced transmitter failures by 50%.

2.3 Lightning and Surge Protection

Outdoor transmitters are vulnerable to lightning strikes and power surges, which can cause severe damage.

Best Practice:

Install lightning rods and grounding systems.

Use surge protectors on power and signal lines.

Ensure proper grounding resistance (typically <4Ω).

Industry Standard: Refer to IEC 62305 for lightning protection design.

3. Wiring Best Practices

Proper wiring ensures accurate signal transmission and reduces noise interference.

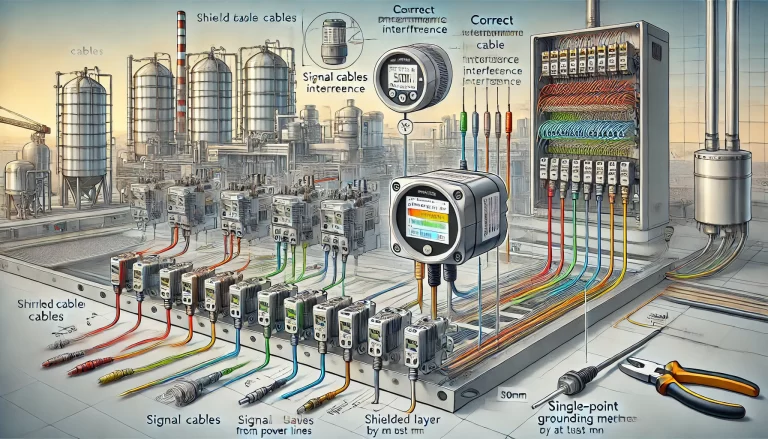

3.1 Use Shielded Cables

Electrical noise from nearby power lines or industrial equipment can interfere with signal integrity.

Best Practice: Use shielded twisted-pair cables, ensuring the shield is grounded at only one end to prevent ground loops.

Example: A pharmaceutical plant experienced fluctuating temperature readings due to unshielded cables near power lines. Replacing them with STP (Shielded Twisted Pair) cables eliminated noise issues.

3.2 Signal Cable Separation

Mixing power and signal cables increases electromagnetic interference.

Best Practice: Maintain a minimum separation of 30 cm between signal cables and power cables. When crossing is necessary, do so at a 90-degree angle.

Case Study: A factory reduced signal noise by rerouting cables into separate conduits.

3.3 Minimize Cable Length

Longer cables introduce resistance and signal degradation.

Best Practice: Keep cable lengths as short as possible. For long-distance transmission, use signal amplifiers or repeaters.

Example: A refinery experiencing signal loss over 200-meter-long cables successfully implemented 4-20mA current loops with amplifiers, ensuring signal integrity.

Conclusion

Optimizing the environment for temperature transmitters enhances measurement accuracy, reliability, and longevity. By carefully selecting installation locations, implementing protective measures, and following best wiring practices, industries can significantly reduce maintenance costs and operational risks. Incorporating these guidelines ensures efficient and trouble-free performance of temperature transmitters in various industrial applications.