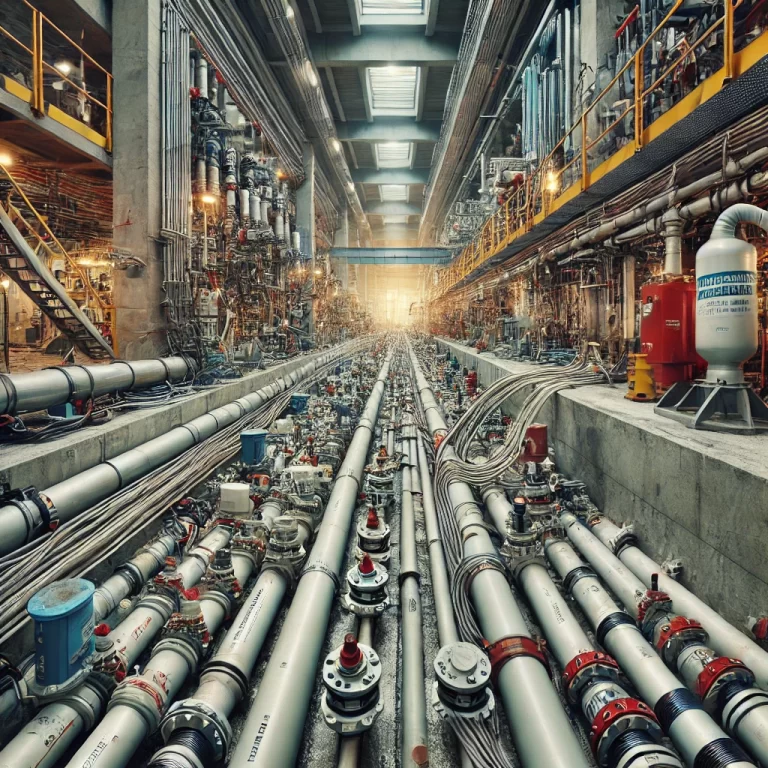

Instrument cable trenches are crucial elements in industrial facilities, particularly in hazardous environments such as chemical plants, power stations, and oil refineries. These trenches often house a multitude of electrical cables used for various instrumentation purposes. Ensuring that these cable trenches are properly sealed for fire and explosion safety is essential in preventing accidents and ensuring the integrity of operations. This article provides a comprehensive guide on how to effectively implement fire and explosion sealing in instrument cable trenches.

1. Selecting Appropriate Fire-Resistant and Explosion-Proof Materials

The first step in ensuring proper sealing of cable trenches is to choose the right fire-resistant and explosion-proof materials. These materials are specifically designed to resist extreme temperatures and contain fires in the event of an emergency.

Fire-resistant Sealant: Fire-resistant sealants such as intumescent fire-resistant caulks or foams are ideal. These materials expand when exposed to heat, filling gaps and blocking the spread of flames and smoke. Common products include fire-resistant putty, silicone-based fire-resistant sealants, and expanding fire sealants.

Explosion-proof Cable Sealing Systems: In environments where there is an explosion risk, explosion-proof sealing systems are necessary. Explosion-proof cable glands and boxes are designed to contain internal explosions without allowing them to spread. These systems are crucial in ensuring the safety of both the cables and the surrounding environment.

2. Proper Seal Design for the Cable Trenches

The layout and design of the sealing systems in cable trenches are critical to their effectiveness. It’s important to ensure that all potential entry points and gaps are sealed securely.

Cable Penetrations: The most vulnerable areas in the cable trench are the points where cables pass through walls or barriers. These penetrations must be sealed with fire-resistant and explosion-proof materials. Special cable sealing systems, such as fire-rated sleeves or grommets, should be used to seal the cables where they enter and exit the trench.

Multiple Cable Penetrations: When multiple cables are present in a trench, the spaces between cables can create gaps that allow fire and smoke to spread. To prevent this, fire-resistant foam or putty should be used to seal the gaps between cables. This ensures that the entire trench remains sealed.

Sealing Trench Joints and Gaps: Any joints, seams, or gaps between trench walls or floor plates should be sealed to prevent the passage of heat, flames, or smoke. Fire-resistant materials like intumescent mastic or fire-rated cementitious sealants should be used in these areas.

3. Installing Fire Barriers or Fireproof Barriers

A key aspect of protecting cable trenches is the installation of fire barriers or fireproof partitions. These barriers help to isolate fire and prevent it from spreading throughout the cable trench system.

Fireproof Barriers: Fireproof barriers can be installed inside cable trenches to provide additional protection in the event of a fire. These barriers are typically made from fire-resistant materials such as fire-rated boards, steel plates, or specially treated cement panels.

Compartmentalization: In larger cable trench systems, compartmentalizing the trench into smaller sections can prevent fire from spreading across the entire system. Fire-resistant bulkheads or fire doors can be used to create these compartments.

4. Ventilation and Heat Management

Cable trenches often contain a large number of cables, and the buildup of heat can be a serious concern. In the case of a fire or explosion, excessive heat can cause the cables to fail or the fire to spread more rapidly. Proper ventilation is essential to ensure that heat and smoke do not accumulate in the trench.

Ventilation Systems: Properly designed ventilation systems help to regulate temperature within the cable trench. This is particularly important in areas where high voltage or high-current cables are used. Ventilation helps to dissipate heat and reduces the risk of overheating and fire.

Temperature Control: In addition to ventilation, temperature control systems such as cooling fans or air conditioning units may be necessary in certain installations to maintain a safe temperature within the cable trench.

5. Routine Maintenance and Inspection

To ensure the continued effectiveness of fire and explosion seals, regular maintenance and inspection are required.

Inspection of Seals: Over time, the fire-resistant materials used to seal the cable trench may degrade or wear out. Regular inspections should be conducted to check for cracks, deterioration, or gaps in the seals. If any damage is found, the seals should be promptly repaired or replaced.

Inspection of Barriers: Similarly, fireproof barriers and fire barriers should be inspected periodically for signs of wear or damage. Any fireproofing material that is damaged should be replaced immediately to maintain the integrity of the fire protection system.

Testing of Systems: It’s important to periodically test fire-resistant and explosion-proof sealing systems to ensure they function as intended. This can involve testing the effectiveness of sealants and barriers under controlled conditions or using specialized fire tests.

6. Compliance with Industry Standards and Regulations

All fire and explosion protection measures for cable trenches should comply with relevant industry standards and regulations. These guidelines ensure that the safety measures implemented are effective and up to code.

National Standards: In many countries, standards for fire and explosion protection in industrial environments are set by organizations such as the National Fire Protection Association (NFPA) in the United States, or similar bodies in other regions. Adhering to these standards ensures that the fire and explosion protection systems meet the necessary safety requirements.

Local Codes and Regulations: In addition to national standards, local codes and regulations must also be followed. These rules may cover specific aspects of cable trench design, installation, and maintenance.

Conclusion

Proper fire and explosion protection in instrument cable trenches is essential to ensure the safety and reliability of industrial facilities. By using the right materials, designing effective sealing systems, incorporating fire barriers, ensuring proper ventilation, and conducting regular maintenance, you can significantly reduce the risk of fire or explosion in these critical infrastructure components. Compliance with relevant standards and regulations is also crucial for ensuring that all safety measures are up to par.

Implementing these best practices will not only safeguard the cable trench systems but also contribute to the overall safety of the facility, protecting both personnel and equipment from potential hazards.