Emergency Stop Switches: Core Safety Logic and PLC Integration Guidelines

In industrial automation environments, the emergency stop (E-stop) button is a critical last line of defense for personnel and equipment. Standard E-stop designs predominantly adopt normally closed (NC) contacts. Under normal conditions, these contacts remain closed, allowing current to pass through the circuit. When pressed, the E-stop mechanically opens the contacts, interrupting the control loop and triggering an immediate shutdown.

This design aligns with the fail-safe principle — even in the event of a wiring fault or contact failure, the circuit will default to an open (safe) state, ensuring the emergency stop function remains effective.

1. Operating Mechanism and Safety-Oriented Structure

The actuation of an E-stop button relies on a mechanical linkage between the button and its base. When pressed, an internal cam or linkage rapidly separates the contact blocks. At the same time, a mechanical latching mechanism is activated, holding the contacts in the open position.

This hardware-first approach ensures that emergency shutdowns are not dependent on PLC software. Even in cases of PLC malfunction, the system can still be halted safely through the hardware circuit.

2. PLC Integration Standards for E-Stop Buttons

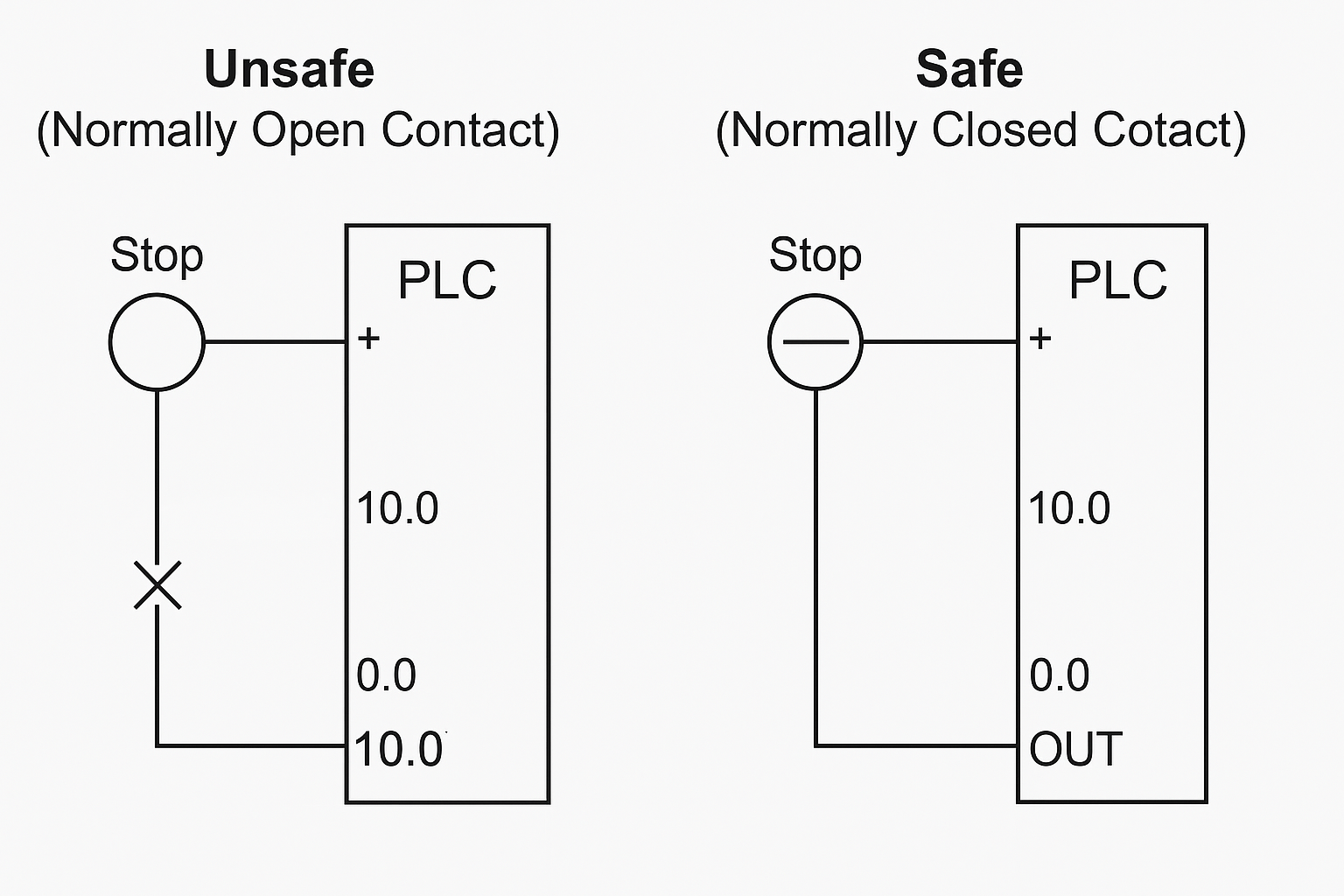

2.1 Using Normally Closed (NC) Contacts — Industry Best Practice

Recommended configuration: NC contact wired in series to a PLC safety input module.

Normal Operation: NC contact closed → PLC input receives HIGH signal (“1”) → equipment runs.

Emergency Pressed: Contact opens → input becomes LOW (“0”) → PLC triggers shutdown routine.

Example Logic:

E-Stop NC contact → [Normally Open instruction in PLC] → Trigger safety shutdown subroutine

Advantages:

Fail-safe operation: Wire disconnection or contact failure = signal loss = PLC interprets as E-stop triggered.

Ensures no blind spots in safety logic.

2.2 Using Normally Open (NO) Contacts — Potential Risks

If NO contacts are used, the logic must be inverted using instructions like LDN or XIO:

Normal: NO contact open → PLC input LOW (“0”) → equipment allowed to run.

Emergency: Contact closes → input HIGH (“1”) → trigger stop.

Drawback:

If the wiring is broken, the PLC continues to receive “0”, failing to detect an E-stop event. This creates a major safety vulnerability, and should only be used in systems with redundant circuits or certified safety PLCs.

3. Three Layers of Safety Enhancement

To improve safety reliability, modern systems often include:

✅ Hardware-Level Isolation

E-stop contacts are wired to a safety relay (e.g., Pilz PNOZ), which can directly cut power to actuators, bypassing the PLC.

✅ Dual-Channel Diagnostic Modules

Safety I/O modules from Siemens (F-series), Allen-Bradley GuardIO, etc., monitor both contact state and wiring integrity in real-time.

✅ Redundant Program Design

Multiple logic checks and independent shutdown subroutines are programmed in the PLC to avoid reliance on a single E-stop signal.

4. Why International Standards Prefer NC Contacts

Consistency: Aligns with most safety relays, field sensors, and shutdown logic.

Failure Tolerance: Wiring or contact failures result in safe-state shutdowns.

Compliance: Meets global safety standards such as ISO 13849, IEC 60204-1, and EN 60947-5-5, all of which emphasize fail-safe design.

🔍 Summary

The E-stop button is more than just a red mushroom switch — it reflects the “safety-first” philosophy of industrial design. By adopting NC contacts, hardware-first shutdown mechanisms, and robust PLC logic, chemical plants and other high-risk facilities can ensure millisecond-level emergency response capabilities.

Recommendation:

For any new construction or safety system upgrade, use NC-type E-stop contacts integrated with safety relays and certified PLC safety modules to meet both engineering best practices and regulatory compliance.