1. Background and Rationale

Under the principle of “No Work Without a Permit,” field instrumentation personnel often face a dilemma in emergency scenarios:

Should they strictly wait for the completion of permit approval before starting work, or

Take immediate action to mitigate the risk and potentially violate the rules?

Since the introduction of the Work Permit Management Policy last year, compliance has been strengthened and workplace safety has improved significantly. However, in practice, conflicts arise between system compliance and emergency response needs.

For example:

Instrument leaks or sudden abnormal parameter drops may demand immediate intervention.

Delays caused by waiting for permits can result in production interruptions, product quality issues, environmental impacts, or even uncontrolled safety incidents.

To address this, a “Operate First, Ticket Later” mechanism is introduced to ensure both rapid response and compliance with safety management requirements.

2. Definition of Emergency Situations and Special Permit Mode

Emergency Situation

An event where instrumentation equipment failure or abnormality:

Directly affects production continuity, product quality, or environmental safety.

Requires immediate intervention to prevent escalation.

Is confirmed by the production unit and approved by the dispatch center.

Operate First, Ticket Later

A special mode allowing authorized personnel to start work immediately without a pre-issued permit, provided that:

The event qualifies as an emergency, and

A permit is completed retrospectively within the required timeframe.

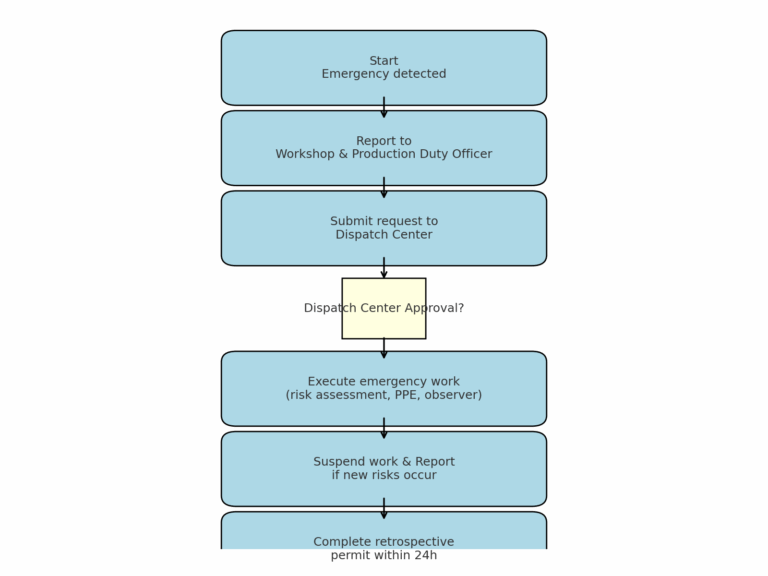

3. Emergency Response Workflow

Step 1 — Reporting

The duty operator in the instrumentation workshop immediately informs both the workshop duty officer and the local production unit duty officer.

Step 2 — Approval

Both duty officers submit a request to the dispatch center with a brief description of the failure, associated risks, and proposed measures.

Only after dispatch center approval may work commence.

Step 3 — Work Execution

Operators switch relevant control loops from automatic to manual mode, or isolate interlocks as needed.

On-site personnel conduct risk assessment, assign a dedicated safety observer, and implement protective measures.

All workers must wear the required personal protective equipment (PPE).

If new risks arise, work must be suspended and reported immediately.

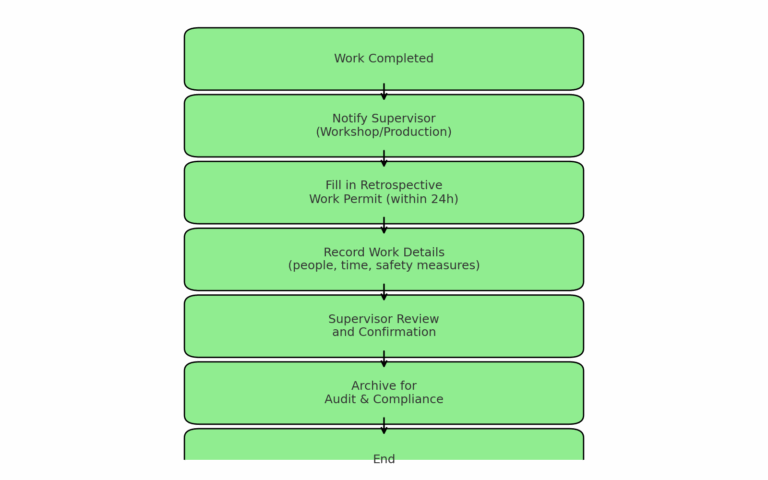

4. Post-Work Permit Completion

Within 24 hours after task completion, the instrumentation personnel must contact the responsible supervisor to finalize the corresponding work permit.

The retrospective permit must include:

Details of the work performed

Personnel involved

Start and finish times

Implemented safety measures

Confirmation of compliance

5. Supervision and Accountability

The instrumentation workshop shall conduct regular audits of emergency work cases. Non-compliance will be subject to disciplinary measures in line with company policy. Typical violations include:

Failure to conduct risk identification or appoint a safety observer.

Initiating work without reporting or approval.

Failure to complete retrospective permits within the required timeframe.

6. Key Benefits

Faster Response: Streamlined approval in urgent situations prevents escalation.

Controlled Risk: Clear responsibilities, safety protocols, and monitoring minimize hazards.

Compliance Assurance: Retrospective documentation ensures traceability and accountability.

System Improvement: Enhances both the safety culture and operational resilience of the enterprise.

7. Conclusion

This policy provides a balanced framework between compliance and emergency efficiency. By defining clear responsibilities, workflows, and safety measures, the enterprise ensures:

Rapid handling of emergencies,

Reliable prevention of uncontrolled risks, and

Continuous alignment with national safety regulations and corporate standards.

Ultimately, this approach strengthens the company’s safety management system and builds a more robust defense line for sustainable development.