Does your industry have the need to measure the flow of liquids through a pipe?

If you said “Yes”, then ask yourself if these are semi-liquid/solid materials—like cement, food products, slurry, or a waste treatment stream?

Still answering “Yes?”

If the precise measurement of hard-to-measure materials is a part of your business, then the answer is simple: use an electromagnetic flowmeter.

Heavy industry and manufacturing often have the need to measure the flow of materials through pipes and processes. When the material is a free-flowing liquid, there are many means to do this. However, when the plant is pumping cement, pulp, or slurry, this measurement can become problematic. Many flowmeters depend on a sensor positioned within the inside diameter of the pipe. When dealing with solids suspended in a liquid, this configuration just does not work.

The Solution: electromagnetic flowmeters. These flowmeters are capable of measuring the exact flow of slurry and semi-solid material suspended in liquid with amazing accuracy.

- How do electromagnetic flowmeters work?

Without going into a lot of boring physics, electromagnetic flowmeters—or “mag meters” as they are known in the industry—rely on Faraday’s Law of Electromagnetic Flow Induction. In short, as fluid, cement, or slurry flow through a pipe in which there is a magnetic field, the conductive particles change the voltage in the field. The mag meter detects these changes and uses a microprocessor to compute the flow—with amazing accuracy. The important thing is not so much understanding how they work but trusting that they do work.

With a base in solid physics, electromagnetic flowmeters are industry-proven and are used in processes around the globe as a trusted device in the measurement of flow. This is particularly the case when hard-to-measure materials require precise measurement.

- What industries use electromagnetic flowmeters?

Any industry that requires accurate measurement of fluid flowing through a pipe can take advantage of mag meters. Industries, where they are the flowmeter of choice, include, but are not limited to, the following:

- Cement plants

- Paper mills

- Textile plants

- Oil and gas industry

- Chemical plants

- Food production facilities

- Waste treatment plants

- And many others

The beauty of electromagnetic flowmeters is they are adaptable to almost any situation where it is critical to accurately determine the correct flow through a pipe.

- What does an electromagnetic flowmeter consist of?

The simplicity of design is what makes electromagnetic flowmeters the flow-detection device of choice. Sensors on the pipe measure the flow and send the signal to a converter which relays the flow rate to operators. It really is that simple. Mag meters are extremely reliable and work consistently without the need for constant recalibration.

- What are the pros and cons of an electromagnetic flowmeter?

Pros

- The measuring technology is mature—electromagnetic flowmeters have been in service for years around the globe.

- They can be installed in very large pipes—up to 800mm.

- There is a wide range of flow measurements available: 15 liters/minute up to 40,700 m³/hour.

- Electromagnetic flowmeters are highly accurate and have a measuring accuracy of ± 0.2% of the reading.

- There is a high-reliability factor. The meter readings are tested to ± 0.1% accuracy for repeated readings of known flows.

- High-pressure models are available—up to 1450 psi (100 bar).

- Many models have self-cleaning electrodes/sensors (more about electrodes later).

- Most mag meters can measure bi-directional flow.

- The inlet velocity of materials can vary from 0.1 m/sec to 10 m/sec.

- The flow measurement is not affected by changes in:

- Fluid density

- Viscosity

- Temperature

- Pressure

- Conductivity

- There is no obstruction component in the pipe that can cause pressure/flow loss.

- There are no moving parts.

- Electromagnetic flowmeters are low maintenance.

- They are designed for superior corrosion and wear resistance.

- They can utilize a wide range of power supplies and have excellent Electromagnetic Interference (EMI) resistance.

- Mag meters use super-fast microprocessors (16 bits MCU) that can self-test and self-diagnose.

- Flow measurements range up to 1500:1.

Cons

While the benefits and features of an electromagnetic flowmeter are numerous, there are some situations where they are not the best choice for specific applications. To achieve the most efficiency and accuracy in flow measurement, it is important to understand their limitations.

- Electromagnetic flowmeters can only measure materials that are conductive.

- Nonconductive materials—such as gas and water—cannot be accurately measured by a mag meter.

- The lining of an electromagnetic flowmeter may not be compatible with extremely high-temperature materials.

- If the material to be measured does not have consistent density, the flowmeter may give inconsistent readings.

- Mag meters are sensitive devices. They must be installed according to the manufacturer’s instructions. Components from different brands are not interchangeable.

- Wear and corrosion on the inner wall of the flowmeter can affect accuracy over time. Thinning of the interior wall of the device can cause erroneous readings.

- Equipment in close proximity to the flowmeter that produces electrical interference can affect the accuracy of the flowmeter.

- Areas of high vibration or where magnetic fields exist can negatively affect the performance of a mag meter.

- When used in the service of measuring very viscous materials, it is possible for a build-up to occur on electrodes and adversely affect the accuracy of the device.

- What are the products with which electromagnetic flowmeters can be used?

The beauty of electromagnetic flowmeters is that they can be used with almost any liquid, or better yet, with a variety of classifications of flammable/combustible liquids (Class I, II, & III), hazardous chemicals (strong acids and alkalis), and liquid-solid two-phase suspensions. Before purchase and installation, it is important to consult the manufacturer or dealer to ensure the installation is compliant with the flowmeter’s specific material compatibility.

- What are the types of electromagnetic flowmeters?

Electromagnetic flowmeters are designed for almost any application. Electromagnetic flowmeters can be hard-wired for direct power supply, or, be battery operated where hard wiring is not feasible. Battery-operated flowmeters are an excellent choice because lithium batteries can provide reliable power to the device for periods up to three (3) years and longer, depending on the battery specified.

Electromagnetic flowmeters can be read directly at the device, or remote reading options are available. Remote reading options include mag meters that are hard-wired to a read-out device in the operations room. When hard wiring is not feasible or too costly, electromagnetic flowmeters can be outfitted with a base-station type radio network system. This type of system can broadcast the flowmeter readings for distances up to 1000 meters to a central location where operators can monitor the flow without traveling to the device.

Base-Station Remote Reading Flowmeter Sanitary Flowmeter

Depending on the measuring service required, electromagnetic flowmeters can be specified for particular applications. In addition to measuring hazardous substances, mag meters for food substances or other “sanitary” materials are available when guarding against contamination is a priority.

Important Information

Once you have decided on an electromagnetic flowmeter, there are several important factors to be considered for safe and efficient operation. Always follow manufacturer instructions.

Basic safety factors when using any mag meter include:

- Use only compatible materials. Consult the product specifications to ensure that the materials to be measured are compatible with the flowmeter housing and components.

- Observe all safety precautions during installation, maintenance, and calibration of the flowmeter, particularly when the meter is installed in the service of measuring hazardous materials.

- When the flowmeter is installed in the service of measuring flammable and/or combustible liquids, observe all safety precautions to prevent fire or explosion. Establish a fire watch during installation, maintenance, and calibration of the device.

- When working in hazardous environments, observe all local safety procedures and precautions.

- Exercise caution when handling the flowmeter. Given the sensitivity of the device, even minor damage can affect the calibration and operation of the flowmeter.

- To ensure accurate operation, the flowmeter should be calibrated once a year.

- During purging operations, do not flow compressed air or nitrogen through the device.

- During removal of the flowmeter from active service, use all precautions to protect against spills and have measures in place for spill containment.

Installation of Electromagnetic Flowmeter

Before purchasing an electromagnetic flowmeter, it is important to consider its installation location and how it is installed. There are two (2) parts to this: mounting position and straight pipe run.

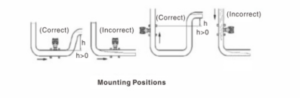

Mounting Position

The mounting position of the electromagnetic flowmeter is crucial. Incorrectly mounted flowmeters can, and often do, result in incorrect readings. To ensure the most accurate operation of the flowmeter, observe these simple instructions regarding mounting locations:

- In order for the flowmeter to read accurately, it is important that the pipes be fully filled with liquids at all times. Partially filled pipes may result in imprecise readings.

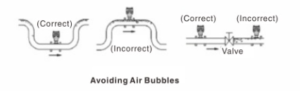

- Proper mounting is important to avoid the accumulation of air bubbles in the pipe. The presence of air bubbles may affect flowmeter accuracy and result in incorrect readings.

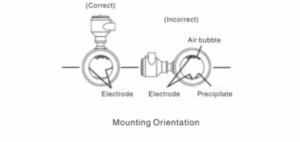

- It is critical that the flowmeter electrodes be mounted parallel to the ground. If electrodes are perpendicular to the ground, air bubbles at the top of the housing or precipitates accumulating at the bottom may cause errors in reading. It is also important to observe this mounting instruction to avoid the accumulation of water in the terminal box.

- Avoid mounting locations that do not have laminar (smooth/straight) flow. Pulsations in the flow—such as may exist in locations on the outlet side of a piston or diaphragm pump—can cause inaccurate readings.

- Avoid locations in close proximity to equipment producing electrical interference such as electric motors, transformers, and variable frequency devices.

- Install the flowmeter in locations where it is easily accessible for maintenance and calibration.

- The isolating liner (PTFE or rubber) of the flowmeter is NOT intended to be used as a gasket material. Standard gaskets, compatible with the material (not included), should be installed to ensure a hydraulic seal.

- During installation, it is important to properly center gaskets to avoid flow restriction or turbulence through the device.

- Do NOT use graphite or any electrically conductive sealing material to hold gaskets in place during installation. This may affect the accuracy of the measuring signal.

Straight Pipe Run

In addition to properly mounting the electromagnetic flowmeter with the appropriate orientation, establishing a sufficient amount of “straight pipe” before and after the flowmeter is vital. This is required to ensure the maximum in accuracy of flowmeter readings. Therefore, pre-planning the installation is crucial to achieving the maximum benefit from the flowmeter.

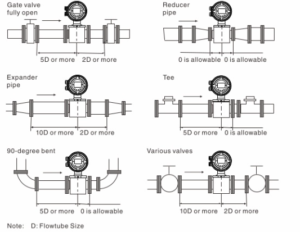

To attain the maximum accuracy in flowmeter performance, the installation should meet the following recommendations for straight pipe runs on both the inlet and outlet sides:

- An equivalent of three (3) inside diameters length of straight pipe on the inlet side

- An equivalent of two (2) inside diameters length of straight pipe on the outlet side

The below diagram illustrates various installations for straight pipe runs when reducers, tees, valves, expanders, or elbows are installed in proximity to the flowmeter.

Troubleshooting

Electromagnetic flowmeters require very little maintenance and only need calibrating once a year. When any malfunction does arise, it can usually be fixed by one of these simple solutions:

- If there is no display – ensure power is supplied, check fuses, and/or adjust the display contrast

- Empty pipe alarm – increase flow rate to fill the pipe, or clean the electrodes

- Flow rate is unstable – ensure proper grounding of the meter, ensure there are no air bubbles in the pipe, and/or ensure the meter is not located to sources of electrical interference.

Conclusion

When a process demands a high degree of precision and the product is not an ordinary liquid, an electromagnetic flowmeter is the device of choice to solve almost any flow measurement problem. The variety of applications and array of models ensures there is an electromagnetic flowmeter for virtually every need. Installations meeting simple parameters guarantee years of reliable service. With little maintenance requirements and the need to calibrate only once a year, electromagnetic flowmeters are easily the best choice when hard-to-measure liquid solutions/mixtures are involved.

For more information on electromagnetic flowmeters, click here.