The economic factors considered in the application of electromagnetic flowmeters should generally include instrument purchase costs, installation costs, maintenance cycles, and flow calibration costs. When applied to trade accounting, the losses caused by measurement errors should be compared.

1. Electromagnetic Meter purchase costs

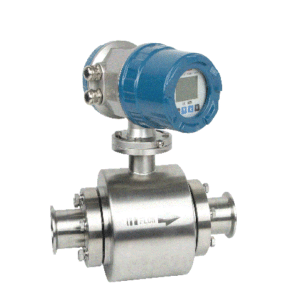

The price of electromagnetic flowmeters can be roughly divided into two categories. One is the high measurement accuracy and multiple functions. The other is the economical type with slightly lower measurement performance and simple functions.

2. Installation costs

Installation costs should include expansion and contraction and other accessories, special pipelines (such as easy to clean pipeline connections), flow rate cable protection sleeves, etc., and commissioning costs before putting them into the operation, etc.

3. Operating costs

There is no pumping energy consumption to overcome the pressure loss caused by the measurement in the operating cost of the pipe segment electromagnetic flowmeter, and the pressure loss of the plug-in electromagnetic flowmeter is also extremely small. The operating cost only includes the power consumption during work, and the cost of this item of contemporary meters is also very low.

4. Calibration costs

After the electromagnetic flowmeter exceeds the verification period of 3-5 years, it is generally necessary to unload the pipeline and re-calibrate the flowmeter on the standard device of the flowmeter. The flow standard device must be a device that is certified by the national reference device through all levels of measurement value transmission. The actual flow calibration cost is about 5%-10% of the electromagnetic flowmeter price.

In actual work, for large-diameter electromagnetic flowmeters, offline verification of the flow sensor is often impossible to remove the pipeline. Therefore, on-site on-site inspection of the flow sensor and on-site laboratory inspection of the converter is used to replace the actual flow verification of the whole machine.