Introduction

The sugar industry is a vital part of the global economy, and it is essential to ensure that the production process runs smoothly. One of the critical aspects of sugar production is the measurement of the main incoming raw juice flow rate. Accurate and reliable measurement is necessary to ensure that the production process is efficient and profitable. In recent years, sugar mills have adopted the use of electromagnetic flowmeters to measure the flow rate of raw juice. In this blog post, we will discuss electromagnetic flowmeters’ importance in sugar mills’ main incoming raw juice.

Benefits of Electromagnetic Flowmeters

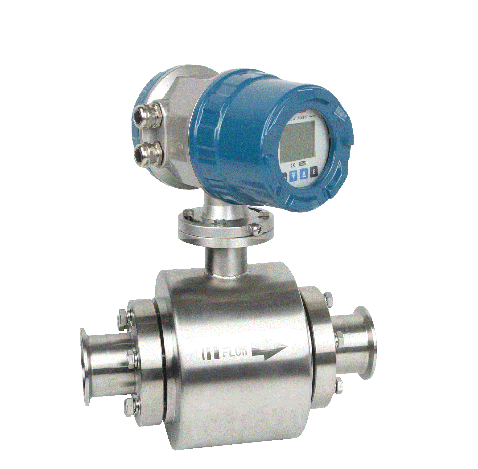

Electromagnetic flowmeters are a popular choice for sugar mills because of their accuracy and reliability. These devices use Faraday’s law of electromagnetic induction to measure the flow rate of the raw juice. The flowmeter consists of two electrodes and a magnetic field. When the raw juice flows through the meter, it produces a voltage that is proportional to the flow rate. The device then calculates the flow rate using the voltage signal.

One of the main benefits of electromagnetic flowmeters is that they can accurately measure the flow rate of the raw juice, regardless of the juice’s viscosity or temperature. Unlike other types of flowmeters, electromagnetic flowmeters do not have moving parts, which reduces wear and tear and increases their lifespan. Additionally, electromagnetic flowmeters are easy to install and maintain, which reduces downtime and improves efficiency.

Importance of Accurate Flow Measurement in Sugar Mills

Accurate flow measurement is essential in sugar mills because it affects the quality and quantity of sugar produced. The main incoming raw juice is used to produce sugar, and any inaccuracies in the flow rate measurement can result in inconsistencies in the sugar produced. Inaccurate measurements can also lead to overproduction or underproduction of sugar, resulting in losses for the mill.

Moreover, accurate flow measurement is necessary for the optimization of the sugar production process. By measuring the flow rate of the raw juice accurately, sugar mills can adjust the production process to ensure that it runs efficiently. This can result in significant cost savings and increased profits for the mill.

Conclusion

The use of electromagnetic flowmeters in sugar mills’ main incoming raw juice is a game-changer for the sugar industry. These devices provide accurate and reliable flow rate measurements, which are essential for the production process’s efficiency and profitability. Sugar mills that have not yet adopted electromagnetic flowmeters should consider doing so to improve their production process’s accuracy and efficiency.