Conductive fluids

Metals are famously conductive materials for heat and electricity due to the presence of free electrons and ions. Similarly, some fluids are also conductive and possess free ions and electrons due to which it conducts electricity. This property of a fluid is referred to as conductivity which is measured in micro Siemens (µS). Water is a poor conductor of electricity; however, if a salt such as Sodium Chloride (NaCl) or Ammonium Chloride (NH4Cl) is added to it, the solution becomes conductive.

Their role in the industry

Conductive fluids are used in chemical processes to produce different products. For example, black liquor and bleach are used in paper, pulp, and textile industries; ethyl alcohol and isopropyl alcohol are diversely used in personal care products, pharmaceuticals, and the food industry.

Why their measurement is necessary?

Accurate flow measurement of fluid chemicals is necessary for every process to obtain a high yield. Volumetric flows are adjusted to maintain levels, concentrations, pressures, temperatures, and time in any production process. Moreover, such flows are assured through the selection of the right flow meters.

What options are available?

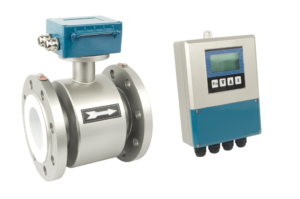

When conductive solutions and mixtures are being used in manufacturing processes, their flows are measured by Electromagnetic flow meters. These are also called magnetic flow meters or simply mag meters.

How do electromagnetic flowmeters work?

The conductivity of conductive fluids is exploited to measure flow. An electromagnetic flowmeter works on the same principle as being used in a dynamo to produce electricity. When a conductive fluid passes through the electromagnetic field, a voltage or electromotive force (emf) induces. This induced voltage or emf is directly proportional to the velocity of the fluid passing through the meter. The velocity of the fluid is then calculated into the volumetric flow rate.

Calibration

Electromagnetic flowmeters also require calibration for accurate measurement of the fluid flow. A signal generator is used to check the operation and the calibration of the meter. Different flow rate signals, according to the range of the meter, are provided by the calibrator to conduct a 5-point calibration process.

Standards

International Organization for Standardization (ISO) also provides guidance on the use of industrial electromagnetic flowmeters for conductive fluids. The document is named ISO 20456:2017 which deals with the electromagnetic flowmeter of different types of field coils and power supplies.

Similarly, American Water Works Association (AWWA) has also prepared a standard named ANSI/AWWA C751-19. This standard explains the minimum requirements for the use of electromagnetic flowmeters; however, it does not describe specifications for the meters. This standard is also approved by American National Standards Institute.

Installation

These flowmeters require special attention during installation and commission. These meters should not be installed on the highest point in the pipeline or in a downward direction. A valve should be installed downstream of the meter when the fluid drop is more than 5 meters. Further, these meters require 10D of pipe length upstream and 5D of pipe length downstream. And pump should always be installed upstream of the meter not downstream.

Operational Troubles

While operating the flowmeter, there could certain problems that can be resolved by considering the best operational practices suggested by the manufactures. For example, when the measurement of a calibrated flowmeter is not accurate, there could be wrong parameters inserted in the software of the meter or the pipeline is not completely filled. Sometimes it happens that the reading of the flowmeter is not stable, it is possibly due to the presence of air in the pipeline, grounding cable may be detached, or electromagnetic interference is nearby which is affecting the reading.

Conclusion

The best choice for conductive fluids is an electromagnetic flow meter or mag meters. These meters are accurate, reliable, standardized, require no mechanical maintenance, and are available in a large range.