INTRODUCTION

Water, which is in abundance on planet Earth is the primary and most important sustenance of life on it, as it is an essential resource in human activities including human production and industrial works.

As human society developed and got more complex—especially with the radical improvements in technology—problems such as low availability of water (even though the planet is 70% covered by H2O) and severe pollution of water, its habitats, and the environment, have become very disturbing increasing variables. The complexity of the Earth’s ecosystem as a whole is one not fully understood by man, especially the water-based ecosystem which has a wide array of living creatures with more being discovered daily.

Also, in human industrial activities, a proper example is printing and dyeing which is rapidly developing, and a significantly large amount of industrial wastewater is produced during the production process. Ignoring the need to treat these waters poses serious threats to the ecological environment and human health in the long run.

To print and dye wastewater is simply the wastewater evacuated during the various segments of the printing process which includes mercerized wastewater, desizing wastewater, printing, and dyeing wastewater, printing and dyeing wastewater, and finishing water.

The high concentration of organic matter and salinity found in these wastewaters discharged by small and medium printing and dyeing plants to the environment is a threat as nature finds it difficult to degrade organic matter not to mention at high concentration levels.

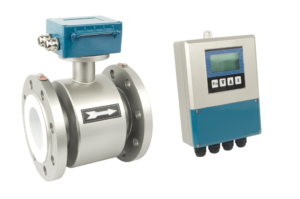

To curb this process, a solution in which the water has to be treated has been devised but there stood the problem of how to monitor the flow of the water and know when they are safe enough to be reintroduced into the ecology. That is when the electromagnetic flowmeter with its unique characteristics comes to the fore. One would wonder how a flowmeter would help in the correction of the wastewater, especially that coming from a printing and dyeing plant. Well, you have to look at the features and characteristics of the electromagnetic flowmeter, just to give a sneak peek, the flowmeter has the ability to survive the elements, especially at their extremes—in temperatures.

FEATURES OF AN ELECTROMAGNETIC FLOWMETER

The unique features or characteristics of an electromagnetic flowmeter generally set them apart from the rest of the competition chiefly because of its working principles and mechanism. These working principles have been the reason why the electromagnetic flowmeter is the most sort after by printing and dyeing plants globally. These features include;

- Having sensors that can be connected on a whim.

- Has multiple electrodes that detect the density, viscosity, and matter constituents of liquids

- Maintenance, installation, and cleanliness are easily achievable as dealing with wastewater requires the flowmeter to have a certain level of easy use.

- Debris accumulation within the tube is prevented thereby ensuring the electromagnetic flowmeter does not give false readings and doesn’t corrode.

- Its accuracy is almost error-free, which is a requirement when dealing with wastewater. Knowing the exact amount of wastewater to recycle and renew helps in determining the best decisions as regards the ecology and environment.

- It displays both negative and positive ranges.

- The properties of the wastewater from the printing and dyeing plants do not interfere with or corrode the flowmeter, be it acidic, alkaline, or at extreme temperatures, the electromagnetic flowmeter’s performance and structural integrity are maintained at optimum.

TYPES OF PRINTING AND DYEING WASTEWATER FLOWMETERS

As with all things, the technology behind the flowmeters continually improved, and wastewater flowmeters also joined the party and improved to meet standards set and required to be met by all printing and dyeing plants, industries, and organizations globally. There are various types of flowmeters adopted by a variety of printing and dyeing plants across the board such as;

- Inertion-type remote display magnetic meter

- Remote-type electromagnetic flowmeter

- Magnetic Flowmeter

- Liquid Turbine Flowmeter

- Handheld ultrasonic flowmeter

- Ultrasonic clamp-on flowmeter

- Thermal mass flowmeter

- Vortex flowmeter

- Mass flowmeter

SUMMARY

The world’s citizenry is constantly trying to make to world a safer place for all creatures big and small on the planet. And a major way to ensure the survival of all species is to improve the availability of clean drinkable water and maintain the purity of the same on the planet.

To this end, the majority of firms that need or deal with a large portion of the earth’s water resource have reverted to the electromagnetic flowmeter as the device provides a lot of solutions in the monitoring and evaluating of wastewater, amongst these industries are those involved in the printing and dyeing industry.

With the laser accuracy of the electromagnetic flowmeter’s readings and the ease of maintenance, the widespread adoption by those in the printing and dyeing industry should not come as a surprise to anyone.