Electrical and instrumentation engineering is critical to modern industrial automation and production systems. Proper installation and commissioning of electrical and instrumentation equipment ensure the safety, reliability, and efficiency of these systems. In this article, we will explore the key aspects of electrical equipment installation, instrumentation installation, and cable laying, along with the necessary checks and procedures to ensure optimal system performance.

Electrical Equipment Installation

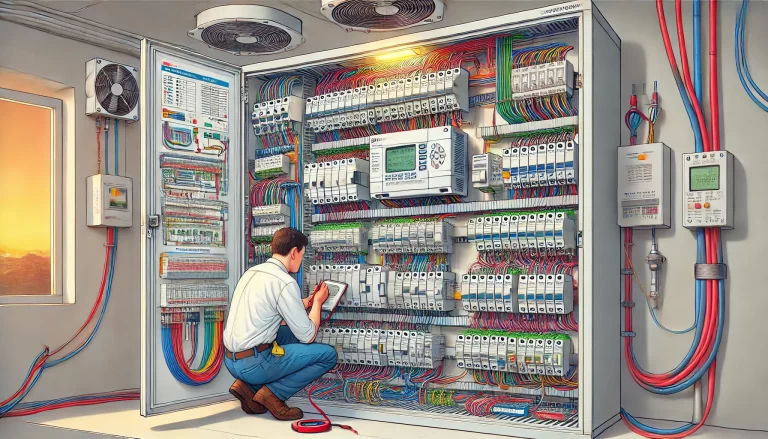

Electrical equipment forms the backbone of power systems and automation control. Ensuring the correct installation and functioning of this equipment is essential for the safe operation of industrial facilities. The following key points must be considered when installing electrical equipment:

1. Grounding Check

Grounding is a vital safety mechanism for electrical equipment, preventing electrical faults from causing damage to equipment and personnel. It provides a safe path for fault currents to dissipate into the ground. During installation, it is crucial to verify that the equipment is properly grounded and that the ground resistance meets design and safety standards. For most industrial systems, the grounding resistance is typically required to be below a specific value (e.g., less than 5 ohms), depending on local regulations and equipment specifications. A proper grounding system ensures that, in the event of a fault, the current will safely discharge into the earth, preventing dangerous voltage buildup that could cause electrical shocks or equipment failure.

2. Wiring and Insulation

Electrical equipment relies on correct and precise wiring for safe and effective operation. After installation, each connection must be thoroughly checked to ensure that wiring is accurate according to the design drawings and that no circuits are miswired. Improper wiring can result in system malfunctions or dangerous short circuits.

Additionally, the insulation quality of cables and wiring must be evaluated to avoid leaks or electrical shorts. Testing insulation resistance using a megohmmeter (or insulation resistance tester) helps ensure the insulation integrity of wiring systems, preventing breakdowns and ensuring operational safety.

3. Operational Status and Monitoring

Once the equipment is powered on, continuous monitoring of the equipment’s operational status is necessary. The equipment should function smoothly under normal operating conditions, without abnormal noises, overheating, or unusual vibrations. These symptoms might indicate mechanical or electrical issues that could lead to equipment damage or failure. Any abnormal heat generation could suggest an overloaded circuit, poor ventilation, or mechanical wear, which must be addressed immediately.

Instrumentation Equipment Installation

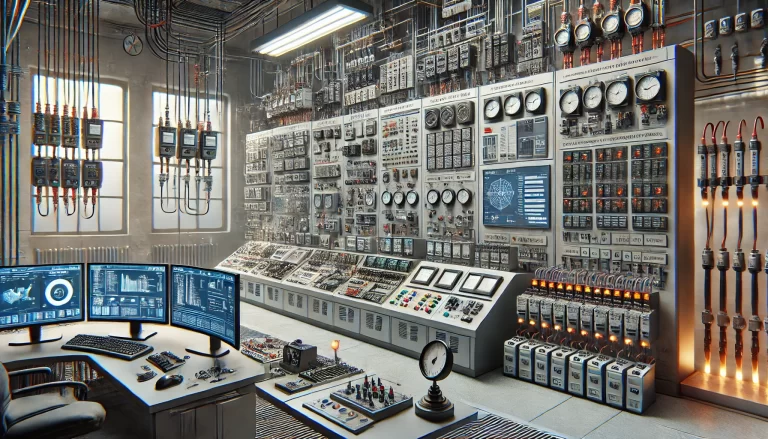

Instrumentation equipment is essential for process control, providing accurate measurements and data to ensure smooth operations. Proper installation of instrumentation devices is crucial for system performance, and attention to detail is required in several key areas:

1. Installation Location

The correct positioning of instrumentation devices, such as sensors, transmitters, and controllers, plays a critical role in their ability to measure and control process variables accurately. The installation location must be chosen to facilitate easy access for operation, maintenance, and calibration, while also adhering to the process requirements. For example, a temperature sensor must be installed where it can accurately measure the process temperature, avoiding areas with significant environmental interference (e.g., direct sunlight or drafts).

2. Wiring and Signal Transmission

Similar to electrical equipment, the wiring of instrumentation devices must be thoroughly checked to ensure accurate signal transmission between field instruments and control systems. Faulty or loose connections can result in erratic or unreliable readings, which may lead to incorrect control actions.

In addition, the signal wiring should be routed to minimize electrical interference from high-voltage power cables, reducing noise in analog signals. Proper shielding and grounding of signal cables are critical to maintaining signal integrity and avoiding disturbances from external sources.

3. Instrument Calibration and Accuracy

Instrumentation devices must meet the design accuracy requirements to ensure that the control system functions as intended. Before commissioning, each instrument must be calibrated to verify that it provides accurate measurements according to specifications. Calibration involves adjusting the instrument’s output to match a known reference, ensuring that the device provides correct readings within the required tolerance range. Regular recalibration is also essential to maintain accuracy over time.

Cable Laying

Cables serve as the physical connections between electrical and instrumentation devices, ensuring power and signal transmission across the system. Proper cable laying is essential for maintaining system reliability and preventing future operational problems.

1. Cable Route Planning

Cables should be laid along routes that are well-planned and free from unnecessary obstacles. The layout should avoid sharp bends, excessive tension, or crisscrossing of cables, as these can cause mechanical stress or damage to the cables. Proper cable management involves installing the cables on trays, ducts, or conduits that provide physical protection and prevent entanglement.

2. Cable Specifications and Insulation

Before installation, it is essential to verify that the cable specifications (e.g., gauge, voltage rating, and type) meet the design requirements. For instance, power cables must be rated to handle the voltage and current levels of the system, while signal cables must have the appropriate shielding to prevent electromagnetic interference (EMI). Additionally, the insulation of cables must be tested to ensure they can withstand operating conditions without degradation or failure.

3. Cable Identification and Documentation

Clear and accurate identification of cables is crucial for ongoing maintenance and troubleshooting. Each cable should be labeled with durable and legible tags, and these labels should correspond to the cable register (or cable schedule), a document that lists all the cables in the system along with their associated details. This register enables maintenance teams to quickly identify and trace cables when necessary, streamlining troubleshooting and repairs.

Conclusion

The installation and commissioning of electrical and instrumentation equipment in industrial systems require meticulous attention to detail to ensure safe and reliable operations. Grounding, wiring, insulation checks, and equipment monitoring are vital steps for electrical equipment installation. For instrumentation devices, proper installation positioning, signal integrity, and accurate calibration are key factors. Finally, cable laying should follow best practices for route planning, specification compliance, and labeling.

By following these guidelines and conducting thorough checks during installation and commissioning, industrial facilities can achieve optimal system performance, reduce downtime, and maintain a high level of safety for both personnel and equipment.