Introduction The elbow flow meter is a specialized type of flow measurement device that utilizes the inertial centrifugal force generated when fluid flows through a curved pipe to create a differential pressure, which is then used to determine the flow rate.

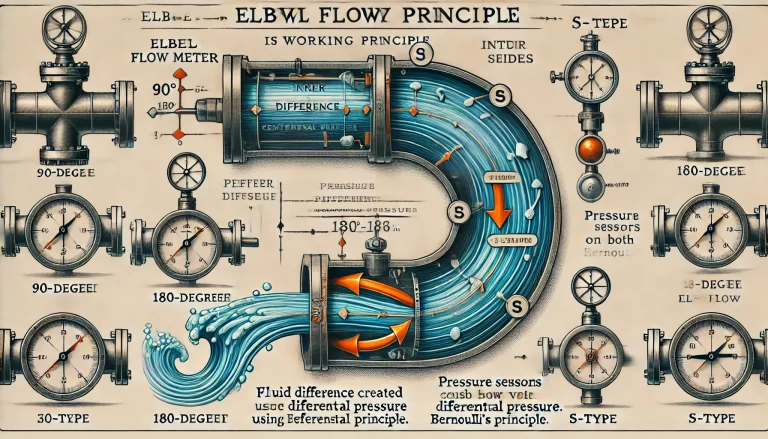

Working Principle of the Elbow Flow Meter The working principle of an elbow flow meter is primarily based on fluid inertia and Bernoulli’s principle. The detailed explanation is as follows:

Fluid Inertia Principle:

When fluid flows through a pipeline and encounters a bend, its direction changes due to the curvature of the pipe.

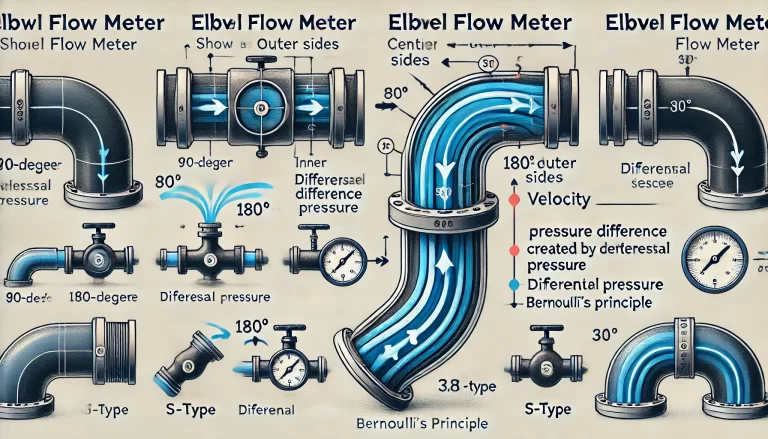

The constrained fluid experiences a circular motion similar to centripetal force, generating a pressure difference on the inner and outer sides of the bend.

The centrifugal force causes the fluid on the outer side of the elbow to exert outward pressure, leading to an increase in pressure, whereas the fluid on the inner side experiences centripetal force, resulting in lower pressure.

Centrifugal Force Effect:

As the fluid passes through the curved section, the curvature forces the fluid to move in a circular path, producing centrifugal force.

The magnitude of this force depends on factors such as fluid velocity, mass (density), and the radius of curvature of the elbow.

Bernoulli’s Principle:

According to Bernoulli’s principle, there is an inverse relationship between fluid velocity and pressure.

In the elbow flow meter, the differential pressure generated between the inner and outer sides of the bend can be used to calculate the fluid velocity, as the pressure difference is proportional to the square of the velocity.

Measurement Process

Differential Pressure Measurement:

Differential pressure sensors are installed on both the inner and outer sides of the elbow to measure the pressure variation.

Due to centrifugal force, the inner side experiences lower pressure, while the outer side experiences higher pressure, creating a measurable pressure difference.

Velocity Calculation:

Using Bernoulli’s equation, the fluid velocity (v) can be derived from the pressure difference (ΔP):

A coefficient dependent on fluid properties and the geometry of the elbow is used to refine this calculation.

Flow Rate Computation:

Once the velocity is determined, the volumetric flow rate (Q) can be calculated using the cross-sectional area (A) of the pipe:

Classification of Elbow Flow Meters Elbow flow meters can be classified based on two primary criteria:

By Measured Medium:

Gas Elbow Flow Meters: Used for measuring gases such as air, natural gas, and industrial gases (e.g., TLB series).

Liquid Elbow Flow Meters: Designed to measure liquids like water, wastewater, and industrial fluids (e.g., TLB-Y series).

By Elbow Angle:

90° Elbow Flow Meters: Commonly used in process pipelines requiring right-angle turns.

180° Elbow Flow Meters: Installed in straight pipelines where a stable differential pressure is needed.

135° Elbow Flow Meters: Used where the fluid path requires a 135-degree turn.

S-Type Elbow Flow Meters: Provides an extended flow path, improving sensitivity and accuracy.

Helical Elbow Flow Meters: Creates a stable helical flow, enhancing measurement precision.

Key Features of Elbow Flow Meters

Simple Structure:

The elbow flow meter consists of a hollow bent tube directly integrated into the pipeline, typically through welding, eliminating the need for additional fittings.

Energy Efficiency:

The absence of obstructions or throttling components minimizes pressure loss, reducing energy consumption in the system.

High Accuracy:

Measurement accuracy can reach levels of 1.5% to 5%, with a repeatability of up to 0.2%.

Fast Response:

The straightforward design allows for rapid response to flow changes, making it suitable for dynamic flow conditions.

Adaptability:

Can withstand high-pressure and high-temperature environments, making it versatile across various industries.

Low Maintenance:

With no moving parts, elbow flow meters require minimal maintenance, making them ideal for remote and hard-to-access locations.

Applications of Elbow Flow Meters Elbow flow meters are widely used across multiple industries due to their advantages in stability, accuracy, and adaptability. Common applications include:

Energy and Utilities: Measuring steam, hot water, and chilled water in power plants and HVAC systems.

Industrial Gases: Monitoring natural gas, compressed air, and process gases in refineries and chemical plants.

Water Treatment: Measuring wastewater, sewage, and industrial process water.

Petrochemical Industry: Used in pipelines transporting fuels and chemicals.

Food and Beverage: Monitoring flow rates in production processes.

Conclusion Elbow flow meters provide a unique solution for flow measurement with their simple structure, high accuracy, and low maintenance requirements. Their application across various industries highlights their versatility and effectiveness in process control and operational efficiency.