The management of spare parts for instrumentation in chemical plants is crucial for ensuring the stability of production processes, controlling maintenance costs, and maximizing economic efficiency. While maintaining a large inventory might tie up substantial funds and warehouse space, insufficient spare parts can lead to costly unplanned downtime, which can far exceed the value of the parts themselves.

To effectively manage spare parts for instrumentation, a systematic and scientific approach is needed. Below are the core strategies and specific steps for optimal spare parts management.

Core Principles: ABC Classification & Criticality Analysis

The foundation of effective spare parts management is prioritization. Not all parts should be treated equally, and a careful classification system should be in place.

ABC Classification (Based on Value)

A-class Spare Parts: High value, but fewer in quantity (about 10-20% of total parts). Examples include mass flow meters, vortex flowmeter sensors, radar level transmitter sets, core sensors for analyzers (e.g., pH electrodes, chromatographic columns), and smart valve positioners.

Strategy: Focused management, precise safety stock calculation, optimal order quantity to reduce capital occupation.

B-class Spare Parts: Moderate value, with a moderate number of items (about 20-30% of total parts). Examples include pressure/differential pressure transmitters, common solenoid valves, temperature transmitters, and I/P converters.

Strategy: Regular management, setting appropriate order points and inventory levels.

C-class Spare Parts: Low value, but numerous items (about 60-70% of total parts). Examples include gaskets, O-rings, fuses, indicator lights, ordinary buttons, and electrical cable connectors.

Strategy: Simplified management, use of quantity-based ordering or the two-bin system. Maintain high safety stock, as the risk of downtime due to stockouts far outweighs the cost of the items themselves.

Criticality Analysis (Based on Equipment Importance)

Critical Instruments: Failure of these parts can cause total production shutdowns, safety, or environmental accidents. Examples include temperature control points in reactors, pressure switches in interlock systems, and gas detectors for hazardous substances.

Strategy: These must be stocked, even considering a “one-for-one” or “one-for-two” backup. Prioritize A-class management.

Important Instruments: Failure may impact plant efficiency, product quality, or cause localized downtime.

Strategy: These should be stocked according to procurement cycles and failure rates, managed as B-class parts.

General Instruments: These instruments have little impact on safety or production, or they feature redundant designs.

Strategy: Limited or no stock is needed. Keep a small inventory of C-class consumables and order as needed.

By combining ABC classification with criticality analysis, companies can set storage priorities. For instance, a critical A-class part like a mass flow meter would receive top priority, whereas a non-critical C-class part like a local indicator for a pressure gauge might be stocked minimally or not at all.

Implementation Steps and Specific Measures

1. Establish an Instrumentation Register and Spare Parts List

This is the foundation for all spare parts management activities. The list should include information such as instrument ID, name, model, manufacturer, technical specifications, location, quantity, and whether the instrument is critical.

2. Perform Spare Parts Demand Analysis and Classification

Using the ABC and criticality analysis methods, classify all spare parts and determine their priority for storage. Additionally, review historical maintenance records to identify parts with high failure rates or those prone to damage (e.g., diaphragm seals, feedback rods, or batteries in flow meters).

3. Inventory Strategy and Safety Stock Calculation

Safety Stock: Calculated to cushion against uncertainties such as supplier delays or sudden demand surges.

Formula: Safety Stock = (Maximum Lead Time – Average Lead Time) × Average Daily Consumption

For critical parts, safety stock can be as simple as one unit, whereas general consumables might require a buffer of three months’ to six months’ worth of inventory.

Reorder Point: Set the point at which new orders should be placed.

Formula: Reorder Point = (Average Lead Time × Average Daily Consumption) + Safety Stock

Economic Order Quantity (EOQ): For A-class parts, calculate the most cost-effective order quantity to balance procurement costs and storage expenses.

4. Select Reliable Suppliers and Build Long-Term Relationships

Establish strong relationships with original manufacturers or authorized agents to ensure quality and timely delivery of spare parts. Consider having backup suppliers, preferably local or with a quick response time, for emergency procurement needs.

5. Standardize Warehouse Management and Use Digital Tools

Dedicated Spare Parts Warehouse: Spare parts should be stored in a clean, dry, and corrosion-free environment. For parts requiring specific temperature or humidity controls (e.g., analyzer components), use temperature-controlled cabinets.

Label Management: Each part should have clear labels including its name, model, location, and entry date. Consider adopting QR or barcode systems for quick information retrieval.

FIFO System: Implement a “First In, First Out” policy to ensure older parts are used first, reducing the risk of aging or expiring parts.

Inventory Management Software: Utilize tools such as ERP (Enterprise Resource Planning) or EAM (Enterprise Asset Management) systems to track inventory levels, generate purchase orders, and record usage history. This ensures more efficient and refined management of spare parts.

6. Regular Evaluation and Dynamic Adjustment

Periodic Inventory Audits: Perform monthly or quarterly stock checks to ensure physical counts align with records.

Regular Review: Conduct bi-annual or annual reviews of spare parts strategies, considering changes such as production line adjustments, new equipment, supplier or lead-time changes, and analysis of historical usage.

Addressing Obsolete Inventory: Parts that have not been used for extended periods should be assessed for obsolescence. If equipment is phased out, consider discarding or liquidating obsolete parts to free up inventory space and capital.

Special Strategies

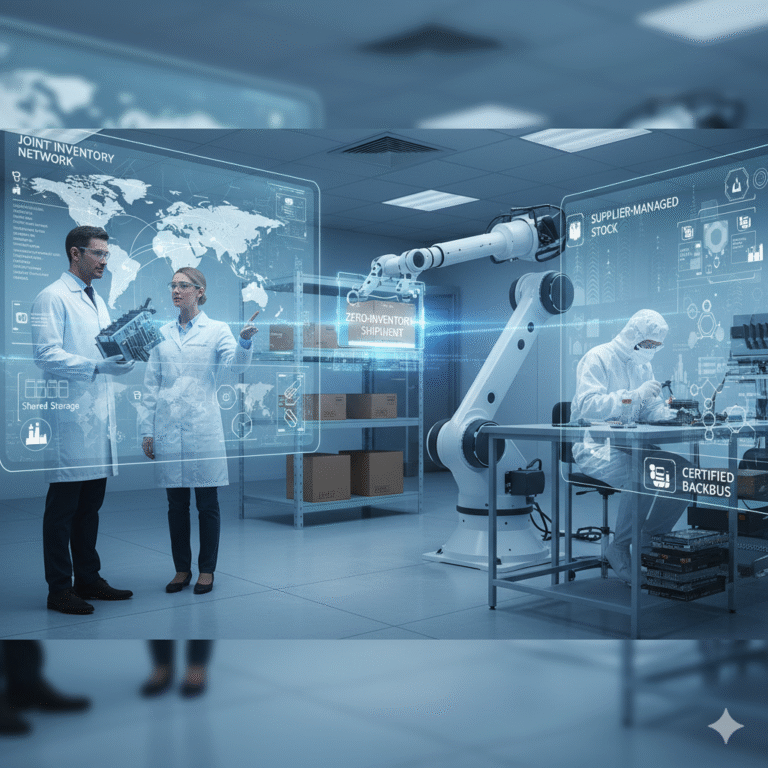

Joint Inventory or Shared Storage: For expensive or infrequently used spare parts (e.g., specialized analyzer modules), consider partnering with neighboring businesses for joint inventory management. This can reduce the cost burden and inventory pressure.

Supplier-Managed Inventory: Collaborate with suppliers to store certain spare parts in their warehouses, allowing for quick access when needed. This “zero-inventory” approach shifts the inventory burden to the supplier.

Repair and Reuse: Instead of discarding faulty items like circuit boards or coils, repair them and keep them as backups. This can significantly reduce the cost of purchasing new items.

Conclusion

The essence of effective spare parts management lies in classification, data-driven decisions, and dynamic optimization. Classification provides the guiding principles for prioritization, while data drives decision-making, ensuring that strategies are based on objective information. Dynamic optimization is an ongoing process, adapting strategies based on the changing realities of production.

The ultimate goal is to find a balance between ensuring production stability and minimizing inventory costs.