Dust explosion hazards are a significant concern in many industries, requiring a systematic approach to identify, classify, and inspect hazardous areas. This guide provides an in-depth overview of combustible dust classifications, the division of hazardous zones, and best practices for inspection and safety management.

1. Classification of Combustible Dusts

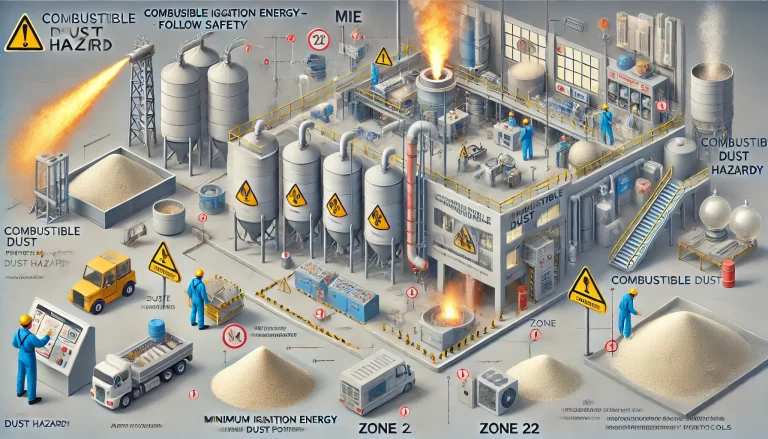

Combustible dusts are fine particles that can ignite or explode when suspended in the air under specific conditions. The classification of these dusts is critical for determining risk levels and implementing safety measures.

1.1 Metal Dusts

- Examples: Aluminum, magnesium, zinc, titanium.

- Hazards: Metal dusts are highly combustible and capable of causing violent explosions. They are often generated during grinding, sanding, or polishing processes.

- Special Considerations: Metal dusts may also react with water or oxidize spontaneously, adding to their hazard potential.

1.2 Non-Metal Dusts

- Examples: Coal dust, sulfur dust, plastic particles, starch.

- Hazards: Organic and synthetic materials can form explosive atmospheres when finely divided.

- Special Considerations: Non-metal dusts often require lower energy ignition sources compared to metals.

1.3 Fiber-Based Dusts

- Examples: Wood dust, cotton fibers, textile materials.

- Hazards: Fibrous dusts are lightweight, highly flammable, and tend to remain airborne for longer periods, increasing the likelihood of secondary explosions.

1.4 Hybrid Mixtures

- Definition: Combinations of different types of dust or dust with flammable gases/vapors.

- Hazards: Hybrid mixtures can exhibit more severe explosive properties than their individual components.

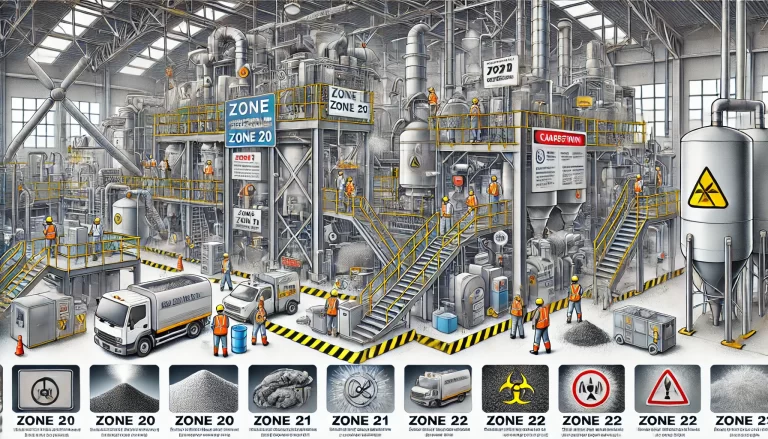

2. Hazardous Area Classification

To mitigate the risks of dust explosions, hazardous areas are divided into zones based on the likelihood and duration of the presence of combustible dust. These zones are defined in standards such as IEC 60079 and EN 50281, as well as guidelines in NFPA 654.

2.1 Zone 20

- Definition: Areas where combustible dust clouds are present continuously or for long periods during normal operation.

- Examples: Inside dust silos, hoppers, and mills.

- Precautions: Use certified explosion-proof equipment and regularly monitor dust accumulation.

2.2 Zone 21

- Definition: Areas where combustible dust clouds are likely to occur occasionally during normal operation.

- Examples: Areas near conveyor transfer points, bagging operations, or around dust collection systems.

- Precautions: Ensure equipment is suitable for Zone 21 environments and implement cleaning schedules.

2.3 Zone 22

- Definition: Areas where dust clouds are likely to occur only under abnormal conditions and for short periods.

- Examples: Storage areas, equipment maintenance zones, or regions where dust may escape during cleaning or emergencies.

- Precautions: Focus on preventing abnormal dust release and ensuring prompt cleanup.

3. Key Inspection Areas

To maintain safety, comprehensive inspections should focus on specific aspects of the facility:

3.1 Equipment and Facilities

- Verify the correct selection and installation of explosion-proof electrical equipment.

- Inspect dust collection systems for wear, blockages, and proper grounding.

- Assess the condition of safety devices such as explosion vents, isolation valves, and spark arresters.

3.2 Dust Accumulation and Concentration

- Conduct regular dust concentration measurements to ensure levels remain below the Minimum Explosible Concentration (MEC).

- Inspect for dust accumulation on surfaces, especially flat or elevated areas.

3.3 Ignition Sources

- Monitor potential ignition sources, such as overheated machinery, sparks from electrical equipment, or static discharge.

- Test for effective grounding and bonding of conductive materials.

3.4 Ventilation and Dust Extraction Systems

- Check the integrity and efficiency of dust extraction systems.

- Ensure proper air circulation to prevent dust cloud formation.

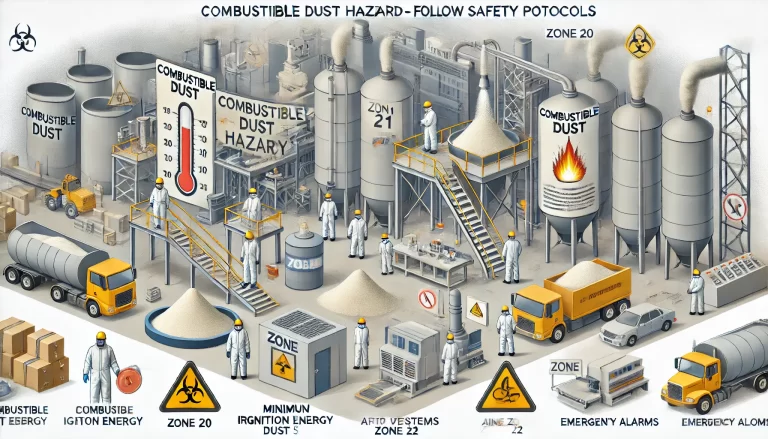

3.5 Emergency Preparedness

- Review the availability and condition of fire suppression systems.

- Verify that explosion relief panels are properly installed and unobstructed.

4. Risk Mitigation Strategies

Preventive measures should be prioritized to reduce the likelihood of a dust explosion. Key strategies include:

4.1 Dust Control

- Implement regular cleaning schedules to remove dust deposits from surfaces.

- Avoid methods that may re-suspend dust, such as dry sweeping or compressed air cleaning.

4.2 Process Design

- Use enclosed systems to minimize the release of dust into the workplace atmosphere.

- Install real-time monitoring devices to detect hazardous dust concentrations.

4.3 Ignition Source Control

- Equip facilities with intrinsically safe or explosion-proof electrical equipment.

- Regularly inspect and maintain all equipment to prevent overheating or sparking.

4.4 Employee Training

- Train personnel on the hazards of combustible dust, safe operating procedures, and emergency response protocols.

- Conduct regular safety drills to ensure employees are familiar with evacuation routes and emergency actions.

4.5 Compliance with Standards

- Adhere to international and local safety standards, such as NFPA 654 (Standard for the Prevention of Fire and Dust Explosions) and ISO/IEC 80079.

5. Critical Safety Standards

Refer to the following standards for detailed guidelines:

- NFPA 654: Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids.

- IEC 60079: Explosive Atmospheres Standards for Electrical Equipment.

- OSHA 29 CFR 1910.307: Hazardous Locations and Explosive Atmospheres.

- ISO/IEC 80079-36: Non-Electrical Equipment for Use in Explosive Atmospheres.

By understanding and applying these principles, industries can effectively manage the risks associated with combustible dust and maintain a safe working environment. For a detailed site-specific safety plan or technical guidance, consulting with certified explosion protection specialists is recommended.