In industrial automation and instrumentation systems, ensuring reliable power delivery is critical to maintaining continuous operation. Two commonly used strategies to improve power system reliability are dual power supply and dual circuit power supply. Although these terms sound similar, they refer to distinct concepts. This article explains the differences and helps you understand which approach fits your application.

✅ What Is Dual Power Supply?

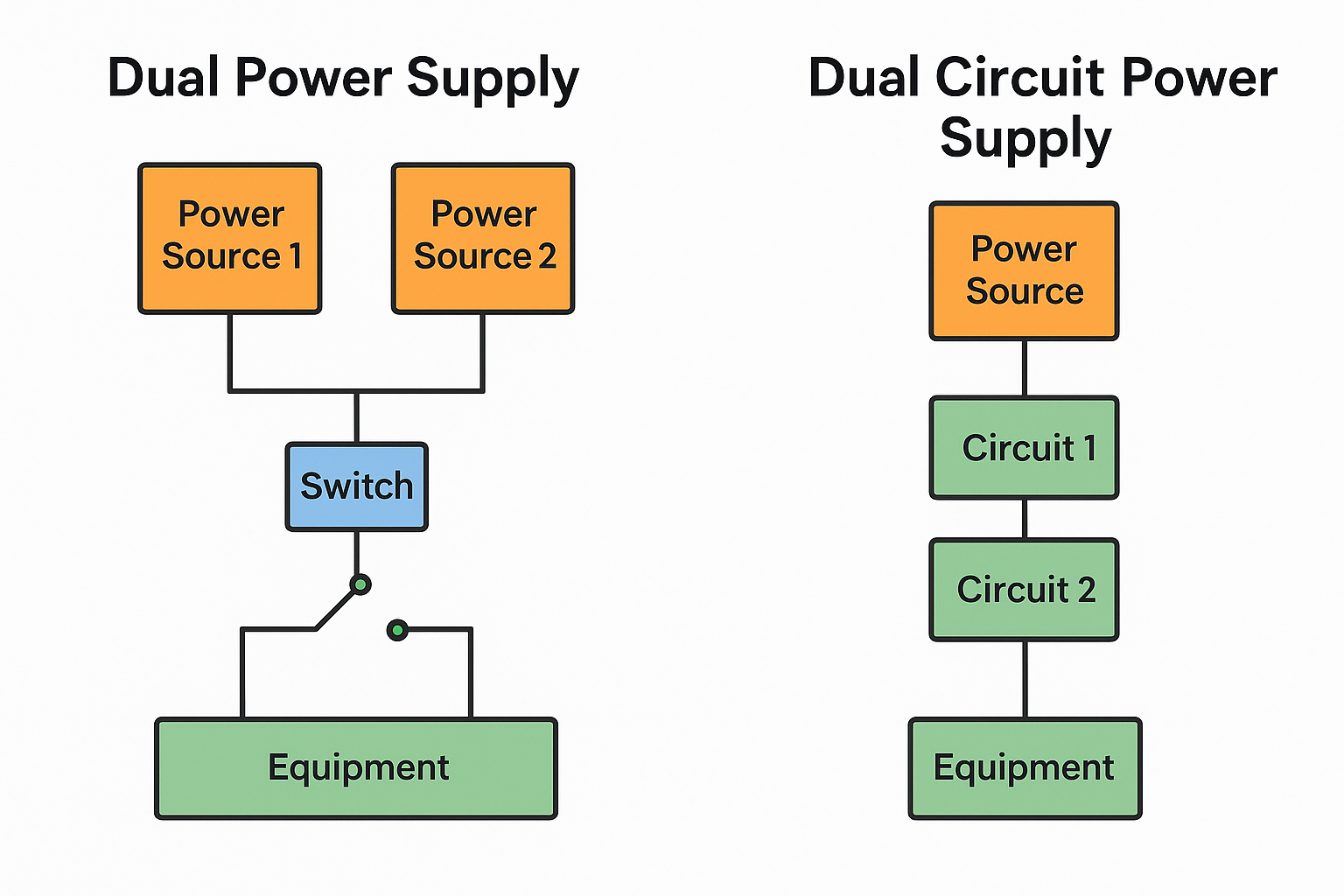

A dual power supply means a system is connected to two independent external power sources: a primary (main) power supply and a secondary (backup) power supply. When the primary source fails or is interrupted, the system automatically or manually switches to the backup source to maintain uninterrupted operation.

📌 Key Features:

Two external power sources (e.g., utility power + UPS or utility power + generator).

Requires an automatic transfer switch (ATS) or manual switching mechanism.

Designed to address external power failures.

Ensures critical equipment keeps running even during outages.

💡 Typical Applications:

Data centers (grid power + diesel generators).

Hospitals (utility + UPS for life-support systems).

Industrial control rooms (main + standby power).

✅ What Is Dual Circuit Power Supply?

A dual circuit power supply refers to a design where a system’s internal power delivery is divided into two independent supply circuits. Even if both circuits rely on the same external power source, this redundancy ensures that if one circuit fails internally, the other can continue supplying power to critical components.

📌 Key Features:

Single external power source but with two independent internal power circuits.

Reduces risk of internal single-point power failure.

Focuses on equipment-level reliability.

Often involves automatic internal switchover.

💡 Typical Applications:

Field instruments such as transmitters and gas detectors.

Critical communication systems.

Power modules inside PLCs or DCS controllers.

🔥 Dual Power vs. Dual Circuit: A Quick Comparison

| Aspect | Dual Power Supply | Dual Circuit Power Supply |

|---|---|---|

| Power Sources | Two independent external sources | One external source split into two circuits |

| Failure Protection | Protects against external power outages | Protects against internal power failures |

| Switching | Automatic or manual external switching | Internal automatic switchover |

| Cost | Higher (requires additional power sources) | Lower (internal design optimization) |

| Typical Use Cases | Hospitals, data centers, industrial plants | Instruments, controllers, embedded systems |

🌟 Combining Both for Ultimate Reliability

In mission-critical systems, dual power supply and dual circuit power supply are often used together. For example, a process plant may use dual power feeds (main grid + UPS) to its control room, while the DCS controllers inside feature dual internal circuits to ensure no single point of failure.

This layered approach helps achieve maximum uptime, even in harsh industrial environments.

📖 Conclusion

Dual power supply ensures your system has an alternative power source in case of external failures.

Dual circuit power supply ensures your system can still operate even if part of its internal power delivery fails.

For high-reliability applications, understanding and implementing both strategies where appropriate is key to minimizing downtime and avoiding costly interruptions.