Creating an effective and reliable Programmable Logic Controller (PLC) program requires careful attention to various critical aspects. An excellent PLC program should meet specific standards to ensure reliability, ease of maintenance, and safety. Here’s a detailed look at the essential characteristics that a high-quality PLC program should embody:

1. Reliability

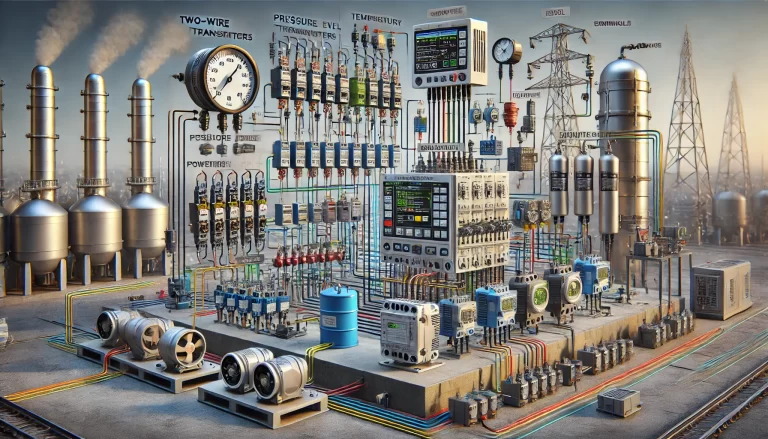

The core function of a PLC program is to control industrial processes, often in critical environments like manufacturing, utilities, and automated systems. Reliability is paramount as any downtime or malfunction can lead to significant losses. To ensure reliability:

- Code should be free of errors that could cause the program to crash or behave unpredictably.

- Contingency plans, such as error-handling routines, should be included to allow the program to handle unexpected situations gracefully.

- Regular testing under various operating conditions can help ensure the PLC program’s stability in real-world scenarios.

2. Readability

Readability is crucial, especially in industrial settings where different engineers and technicians may interact with the PLC code. Readable code makes maintenance, updates, and troubleshooting much more manageable. To improve readability:

- Use clear and descriptive names for variables, functions, and other elements within the program.

- Structure the code logically, breaking down complex processes into smaller, manageable functions or routines.

- Add comprehensive comments to explain what each section of the code does, why certain decisions were made, and the expected behavior of the program.

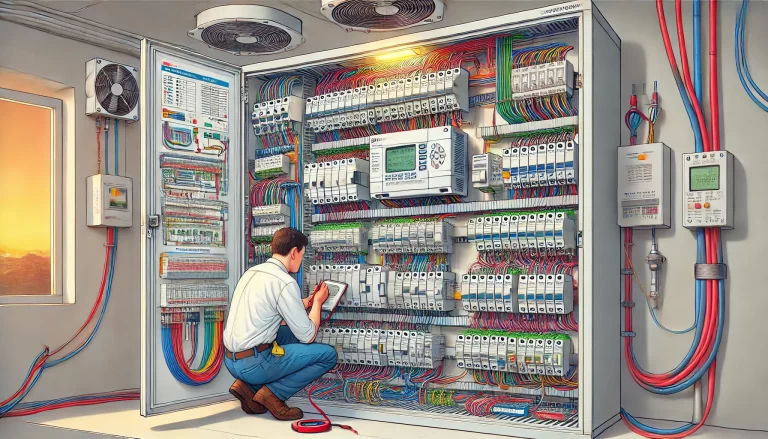

3. Maintainability

PLC programs often require updates and improvements over time. A maintainable PLC program makes these changes as simple and error-free as possible. To enhance maintainability:

- Apply a modular design approach, dividing the program into separate, independent modules that can be maintained or updated without affecting the entire system.

- Keep functions isolated and focused on specific tasks, allowing for individual testing and modification when needed.

- Create a version control system for tracking changes, which can be essential when multiple people work on the program over time.

4. Scalability

Industries frequently need to adapt and grow, adding new machinery, expanding operations, or modifying processes. A scalable PLC program is one that can easily accommodate such changes without requiring a complete rewrite. Tips for scalability include:

- Use flexible programming structures that allow new modules to be added without significant changes to existing code.

- Design interfaces between modules to accommodate additional inputs or outputs as the system expands.

- Avoid hard-coding specific values, which can limit flexibility; instead, use variables or configurable parameters where applicable.

5. Safety

Safety is a top priority in any industrial setting, especially when dealing with automated systems and machinery. A good PLC program must ensure safe operation, protecting both operators and equipment. Safety measures include:

- Implementing fail-safes and redundancies, such as checks for abnormal conditions that could trigger a safe shutdown if required.

- Including software interlocks to prevent equipment from operating in an unsafe state or sequence.

- Setting up access controls to limit modifications and operational changes to authorized personnel only, preventing accidental or unauthorized alterations to the program.

6. Real-Time Responsiveness

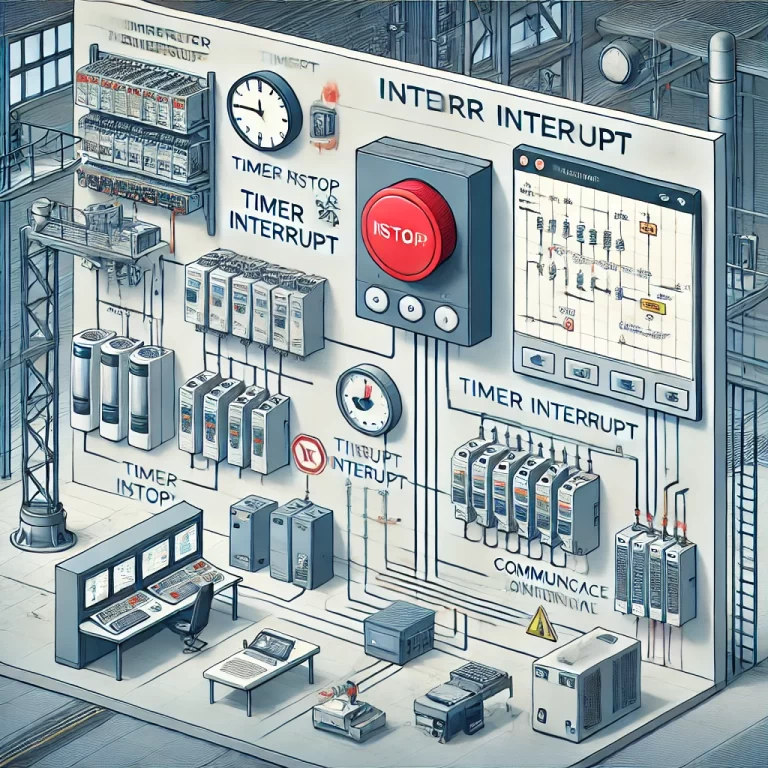

Many industrial processes require real-time control where quick responses to inputs are crucial. A high-quality PLC program must be able to respond instantly to sensor signals, user commands, and changes in system state. For real-time responsiveness:

- Optimize the program to reduce scan time, ensuring the PLC can process instructions quickly and meet the timing demands of the system.

- Use interrupt-based programming when necessary to prioritize critical operations that require immediate action.

- Test the program under conditions simulating real-time demands to validate responsiveness.

7. Ease of Debugging

Debugging and troubleshooting are inevitable, and a good PLC program should make this process as straightforward as possible. To facilitate debugging:

- Include diagnostic routines or status indicators that provide information on system states, sensor inputs, and output states.

- Add status flags or markers that help technicians understand the current operation sequence, making it easier to pinpoint issues.

- Document any assumptions and limitations within the program so that debugging does not lead to incorrect assumptions.

8. Resource Optimization

PLCs have limited memory and processing power, so resource optimization is essential. A well-optimized program ensures that the PLC operates efficiently without unnecessary resource consumption. To optimize resources:

- Minimize memory usage by only creating variables and data structures that are essential.

- Avoid repetitive calculations by storing results in variables if they’re used multiple times within the program cycle.

- Eliminate redundant code or processes that could slow down program execution.

9. Compatibility and Portability

A compatible PLC program can be easily transferred to different hardware platforms or PLC brands if necessary. While this can be challenging due to differences in PLC architectures, some best practices can help:

- Stick to widely used programming standards, such as IEC 61131-3, which provides guidelines for programming languages and structures in PLC programming.

- Avoid using proprietary functions specific to one brand, as these may not be compatible with other systems.

- Use standard data types and structures that are commonly supported across various PLC platforms.

10. Traceability and Logging

Logging and traceability allow maintenance personnel to trace issues back to their origins and understand the program’s history. A traceable PLC program has:

- Error logs or event logs that capture significant events, changes, and errors, providing a timeline of what has occurred within the program.

- Comments and documentation that detail the program’s development process, including major changes, which can be invaluable during troubleshooting.

- Version tracking to ensure that changes can be traced to specific engineers or technicians, providing accountability and insights into code modifications over time.

Conclusion

A high-quality PLC program is the backbone of any automated industrial system. By focusing on reliability, readability, maintainability, scalability, safety, real-time responsiveness, ease of debugging, resource optimization, compatibility, and traceability, engineers can develop robust, flexible, and future-proof PLC programs. These characteristics are essential to ensure that the program not only performs its intended functions but also adapts to the changing needs of industrial environments while maintaining safety and efficiency.