When working with control valves and actuators, a common question arises:

Do smart valve positioners come in different types for linear and rotary motion?

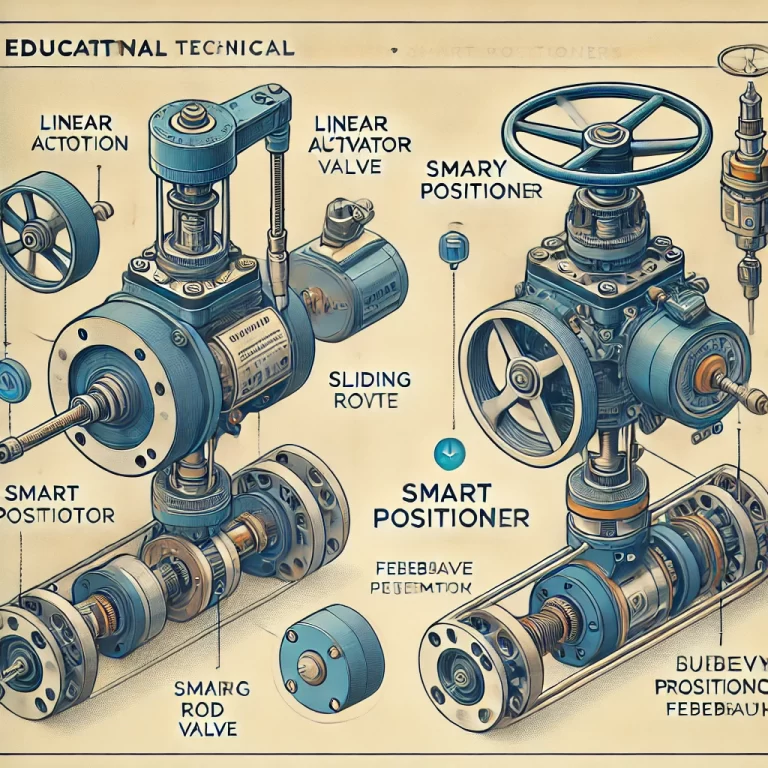

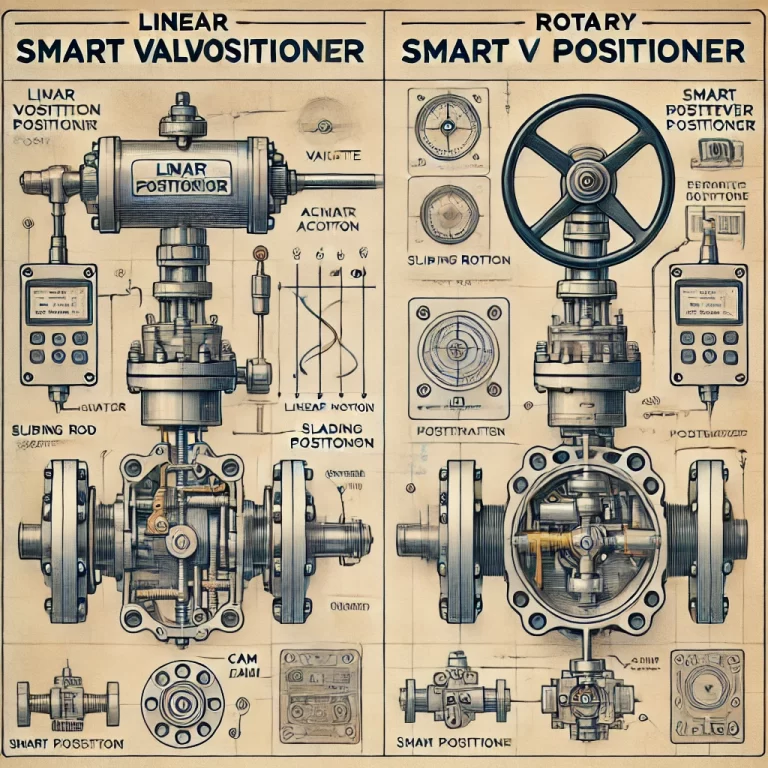

The answer is yes—while the internal control principles remain similar, smart positioners are specifically designed to suit linear and rotary actuators differently.

What is a Smart Positioner?

A smart positioner is a digital device mounted on a control valve to ensure the valve reaches the position dictated by a control signal (typically 4–20 mA). It continuously monitors the valve position through a feedback mechanism and adjusts the pneumatic signal to the actuator to correct any error.

Smart positioners improve control accuracy, enable diagnostics, and often support HART, Foundation Fieldbus, or Profibus protocols.

Key Differences: Linear vs Rotary Smart Positioners

| Feature | Linear Smart Positioner | Rotary Smart Positioner |

|---|---|---|

| Application | For linear motion actuators (e.g., globe valves) | For rotary motion actuators (e.g., ball or butterfly valves) |

| Feedback Mechanism | Typically uses a sliding rod or linear sensor | Uses a rotary shaft or cam linked to actuator movement |

| Mounting Interface | Designed to fit linear actuators’ layout | Designed to fit rotary actuators’ shaft/lever arrangement |

| Valve Stroke | Measures straight-line movement | Measures angular rotation |

| Typical Stroke Range | 0–100 mm or similar | 0–90° or 0–180° |

| Mechanical Linkage | Direct linear linkage to valve stem | Uses lever, shaft, or cam-based angular feedback |

Why the Distinction Matters

Even though both types serve the same control function, choosing the wrong version can lead to:

Improper installation

Inaccurate valve positioning

Mechanical mismatches

Loss of control precision

Examples of Brands and Models

Most major manufacturers provide both versions:

Siemens SIPART PS2: Available for both linear and rotary applications.

Emerson Fisher DVC6200: Versions for sliding-stem and rotary valves.

ABB TZIDC Series: Models tailored for linear and rotary actuators.

Yokogawa YT-3300 Series: Comes with different mounting kits for each application.

Azbil (Yamatake): Smart positioners with mechanical kits for specific motion types.

How to Choose the Correct Type

Identify Actuator Type: Is it linear (e.g., globe valve) or rotary (e.g., butterfly valve)?

Check Valve Stroke: Know whether the valve uses linear displacement or angular rotation.

Review Mounting Requirements: Ensure the positioner fits the actuator’s mounting interface.

Confirm Feedback Method: The positioner’s sensor must match the actuator’s movement style.

Consult the Datasheet: Manufacturers clearly specify motion types for each model.

Final Thoughts

While smart positioners share the same core function—ensuring precise valve positioning—they are not universal in terms of mechanical design. The distinction between linear and rotary applications is crucial for proper selection, installation, and long-term performance.

Always verify the type of actuator you’re working with and consult the manufacturer’s documentation to choose the correct version of a smart positioner.