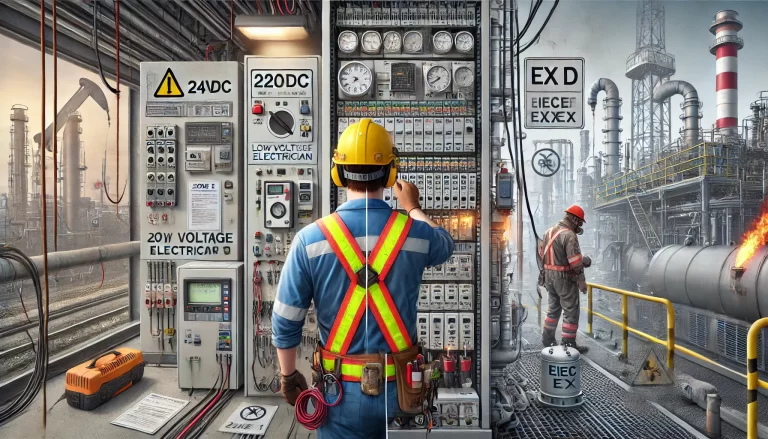

In industrial facilities, instrumentation technicians (also known as instrument fitters or instrument mechanics) play a vital role in maintaining measurement and control systems. Their responsibilities often overlap with electrical work, especially in process industries. This raises an important question: Should instrumentation technicians hold certifications for low-voltage electrical work and explosion-proof electrical installations?

This article explores the necessity of two key certifications: the Low Voltage Electrician Certificate and the Explosion-Proof Electrical Certificate, and outlines when and why each is required.

1. Low Voltage Electrician Certificate

✅ Is It Required? Yes, in most cases

🔍 Why It’s Important:

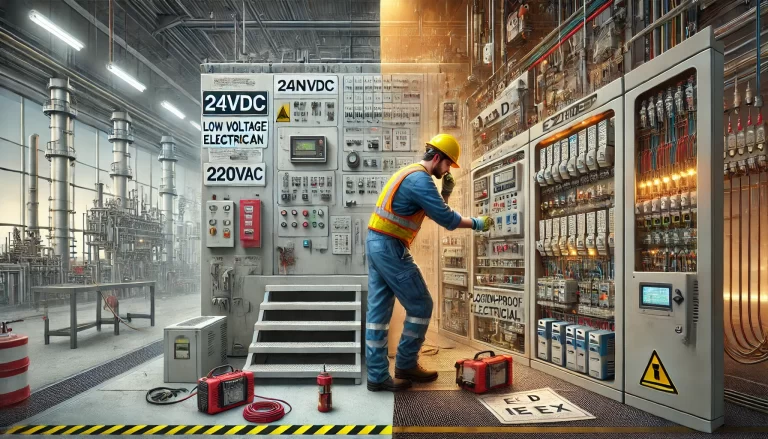

Instrumentation technicians frequently work with power supplies, signal wiring, and control loops that operate at voltages such as 24VDC, 220VAC, or even 380VAC. Tasks may include:

Wiring of instrument panels

Connecting signal cables to PLCs or DCS systems

Troubleshooting powered transmitters or controllers

Installing junction boxes or power supplies

In many jurisdictions, including China, these tasks fall under the scope of “special operations”, and according to safety regulations, any worker performing such tasks must hold a valid Low Voltage Electrical Operation Certificate, also known as a “Special Operator Certificate.”

🧾 Issuing Authority:

This certificate is usually issued by local safety supervision departments (e.g., China’s Emergency Management Bureau) after passing safety training and a qualification exam.

⚠️ Risks Without Certification:

Legal penalties for non-compliance

Increased risk of electrical accidents

Liability issues during safety inspections or incidents

2. Explosion-Proof Electrical Certificate

✅ Is It Required? Only for hazardous environments

🔍 Why It’s Important:

Many industrial facilities—especially in oil & gas, petrochemicals, pharmaceuticals, and mining—are classified as hazardous areas due to the presence of flammable gases, vapors, or dust. In such environments, equipment including:

Pressure and temperature transmitters

Field junction boxes

Control panels or enclosures

must meet explosion-proof standards (e.g., Ex d, Ex ia, Ex nR). Instrumentation technicians who install, maintain, or repair such devices must be trained and certified in explosion-proof electrical work to ensure compliance and safety.

🧾 Common Requirements:

Understanding of area classification (Zone 0, 1, 2)

Familiarity with IECEx/ATEX/GB standards

Knowledge of flameproof, intrinsic safety, and increased safety techniques

🧾 Certification Bodies:

In China, explosion-proof certification is typically issued by certified training organizations under the supervision of the National Safety Production Supervision Department.

3. Summary Table

| Certification Type | Required? | Applicable Situations |

|---|---|---|

| Low Voltage Electrician | ✅ Mandatory | All environments where voltage wiring and electrical connections are involved |

| Explosion-Proof Electrical | ✅ Conditional | Required only when working in hazardous (classified) areas |

4. Final Recommendation

If you are an instrumentation technician or hiring one, ensure the following:

Low voltage certification is a baseline requirement for any industrial work involving electrical connections.

Explosion-proof certification becomes essential when the work environment is classified as hazardous under applicable regulations.

Not only do these certifications ensure regulatory compliance, but they also significantly improve operational safety and reduce liability in case of incidents.