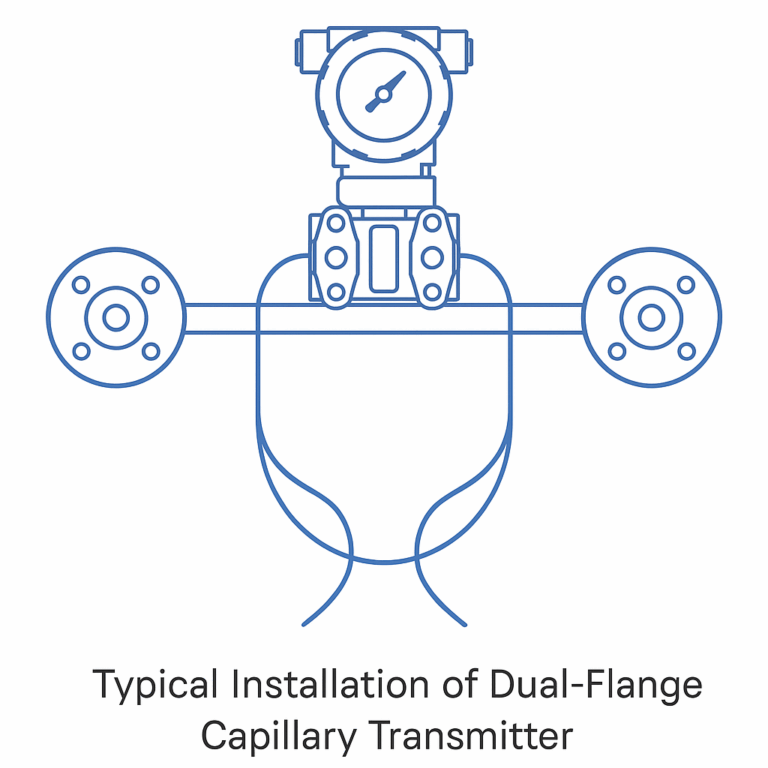

1. General Principle – Insulation Not Always Required

Under normal environmental conditions, the fill fluid inside the dual-flange capillary (commonly silicone oil) has sufficient temperature tolerance. It can adapt to routine ambient variations without additional thermal protection. In such cases, thermal insulation is not mandatory, reducing both cost and maintenance workload.

2. Situations Where Insulation Is Recommended

2.1 Low Ambient Temperature

When the ambient temperature drops below the freezing point of the fill fluid, the fluid may thicken or solidify. This restricts pressure transmission and compromises measurement accuracy. For example, silicone oil significantly increases in viscosity at low temperatures. In cold regions, without insulation or heating, the capillary fluid may stagnate, leading to erroneous differential pressure readings.

2.2 Large Temperature Fluctuations

Even if the ambient temperature is above the freezing point, wide daily temperature swings may cause density variation in the fill fluid. This results in static pressure changes, zero drift, and increased measurement errors. Outdoor installations in regions with large day–night temperature differences are typical cases where insulation is advised.

2.3 Special Installation Locations

Capillary tubes exposed to direct sunlight, hot pipelines, or cooling sources are subjected to strong temperature variations. Insulation minimizes these environmental effects and ensures stable measurement.

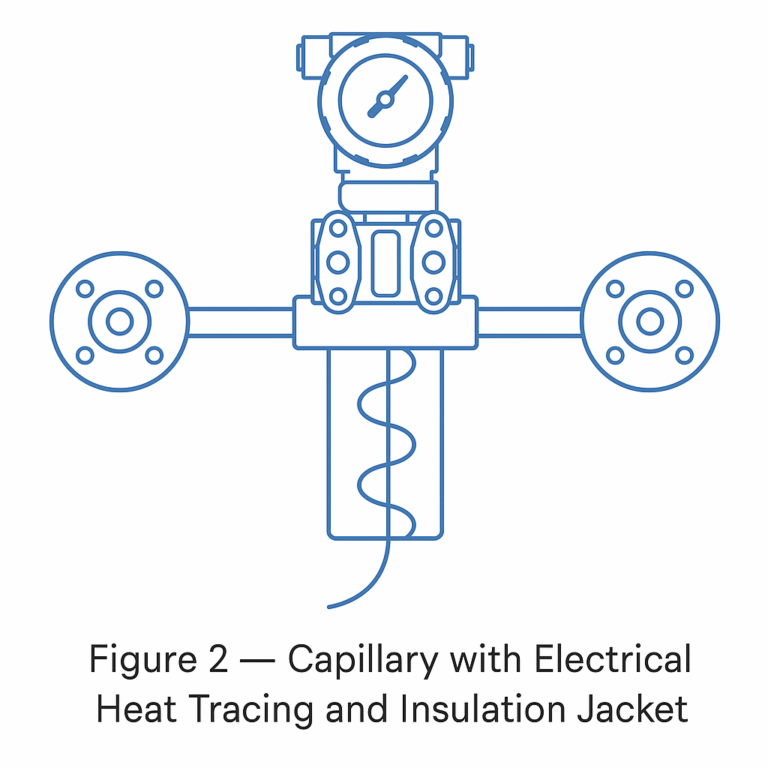

2.4 Risk of Overheating During Heat Tracing

When using electrical or steam tracing for freeze protection, excessive heating must be avoided. Overheating can vaporize the fill fluid and damage the transmitter. Controlled insulation is therefore critical.

3. Thermal Insulation Methods

3.1 Electrical Heat Tracing with Insulation Jacket

Electrical heating tapes can be installed along the capillary and wrapped with insulation material. This ensures stable temperature control but requires careful monitoring to avoid overheating.

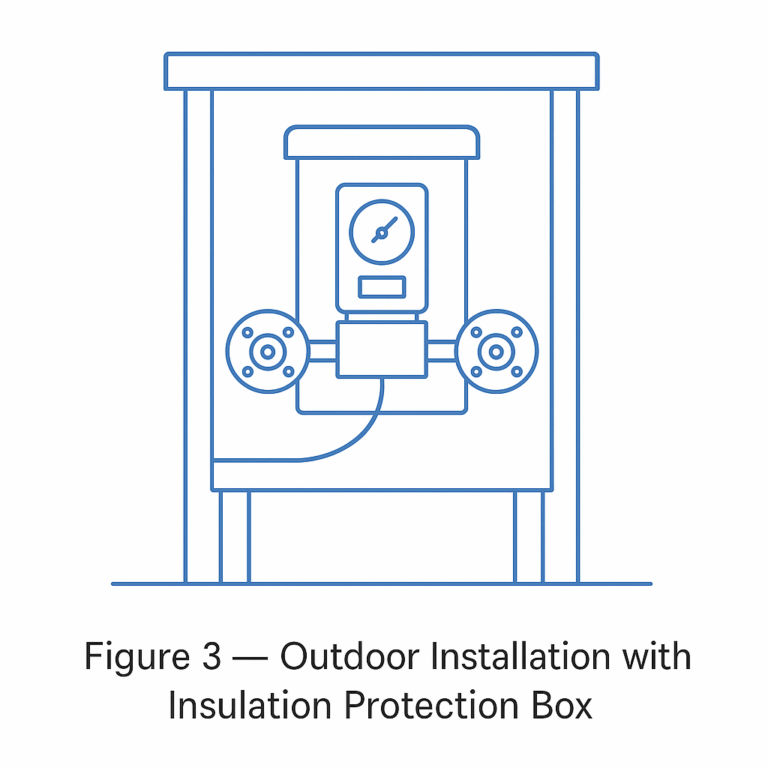

3.2 Instrument Protection/Insulation Boxes

Mounting the dual-flange transmitter in a thermal insulation box provides both environmental protection and temperature stability. It safeguards sensitive electronics (LCD display, PCB board) and offers partial insulation for the capillary lines.

3.3 Steam Tracing or Thermal Blankets (Optional)

In some chemical plants, low-pressure steam tracing or thermal blankets are applied for freeze protection. The heating intensity must be carefully adjusted to match the fill fluid’s operating range.

4. Applicable Standards and Guidelines

GB50264-2013 — Design Code for Industrial Equipment and Pipeline Insulation

Specifies when insulation is required, such as:Outer surface temperature > 50 °C with process need to reduce heat loss.

Outer surface temperature ≤ 50 °C but medium temperature must be maintained to prevent solidification.

For dual-flange capillaries, if fluid temperature variation threatens normal operation, insulation should follow these guidelines.

Manufacturer Specifications

Leading suppliers (e.g., Rosemount, Yokogawa EJA) specify temperature ranges for different fill fluids. If local ambient conditions exceed these limits, thermal insulation or tracing must be applied.

5. Practical Reference Table

| Condition | Insulation Requirement | Notes |

|---|---|---|

| Ambient ≥ fill fluid freezing point, stable temperature | Not required | Normal environments |

| Ambient < fill fluid freezing point | Required | Prevents solidification and blockages |

| Day–night temperature swing > 20 °C | Recommended | Reduces zero drift and error |

| Installed near heat/cooling source | Recommended | Minimizes thermal interference |

| Steam/electrical tracing applied | Carefully controlled | Avoid overheating and fluid vaporization |

6. Conclusion

The need for thermal insulation of dual-flange capillaries depends on ambient temperature, thermal stability of the fill fluid, and installation environment.

In mild climates, no insulation is needed.

In low-temperature, high-variation, or special installations, proper insulation is essential to maintain measurement accuracy and ensure reliable transmitter performance.