1. Introduction

Steam temperature is one of the most critical parameters in thermal power plant operation. Compared with drum water level control, which has evolved into the classical three-element control system, steam temperature regulation remains highly complex. Multiple disturbance factors—ranging from load fluctuations to flue gas conditions and desuperheating water flow—can influence the dynamic behavior of steam temperature. These disturbances differ in magnitude, delay, and inertia, making their control challenging.

2. Major Disturbance Factors

2.1 Unit Load Fluctuation

When unit load increases, the boiler responds by increasing fuel supply, enhancing combustion, and raising flue gas temperature and velocity. Consequently, heat absorption by the boiler rises.

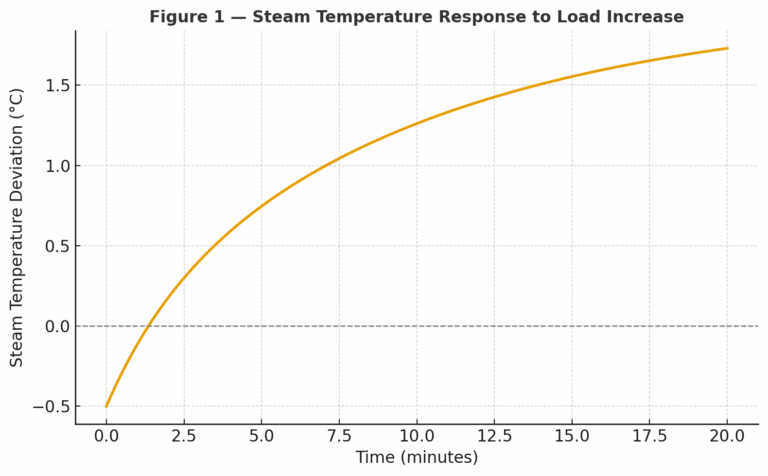

Radiant Section: Experiences temperature changes first, with small delay but large inertia.

Convective Section: Shows larger delay and inertia.

Dynamic effect: Steam temperature initially drops slightly (due to higher mass flow of steam) and then increases significantly as convective heat absorption dominates.

2.2 Flue Gas Heat Transfer Disturbance

The outlet temperature of the superheater depends on the balance between heat supply and heat absorption. Any factor that alters the flue gas temperature or velocity disturbs steam temperature.

Key contributors:

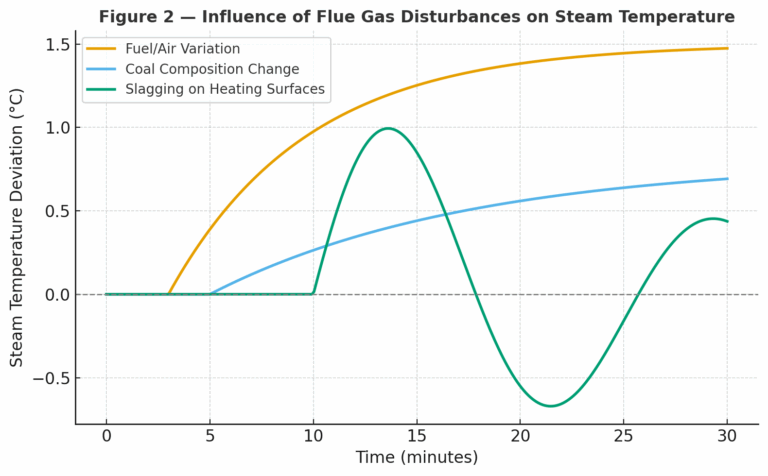

Variation in fuel feed and air supply.

Change in coal quality/composition.

Slagging or fouling of heating surfaces.

Shift of flame center position.

These factors, collectively termed heat transfer disturbances, are difficult to predict or compensate due to limited monitoring points inside the furnace.

2.3 Desuperheating Water Flow Disturbance

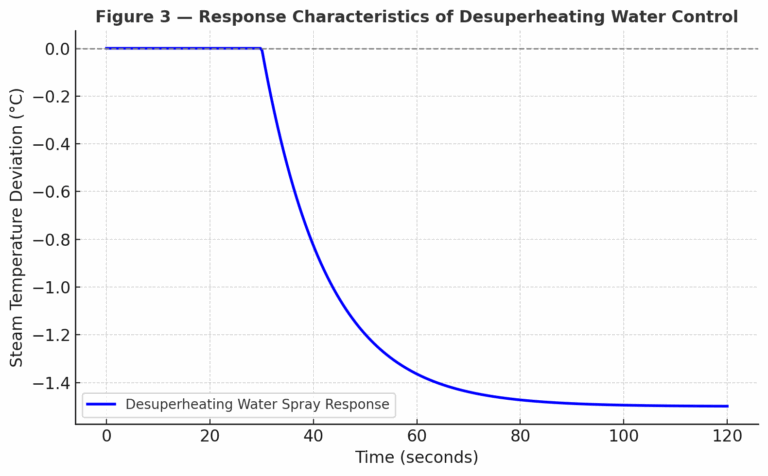

The most direct and widely applied control method is desuperheating water flow regulation.

Advantages: Quick response, intuitive control.

Disadvantages:

For primary superheater, effect is acceptable.

For reheater, excessive spray water reduces unit efficiency (pumped feedwater bypasses the turbine expansion).

Typical delay: 30–60 seconds, depending on boiler size and flue gas duct length.

Improper design often leads to:

Control valves always operating in very low range (<20%).

Valves fully opened yet failing to meet requirement.

Both indicate insufficient design margin, resulting in unstable operation.

3. Comparative Analysis of Disturbance Effects

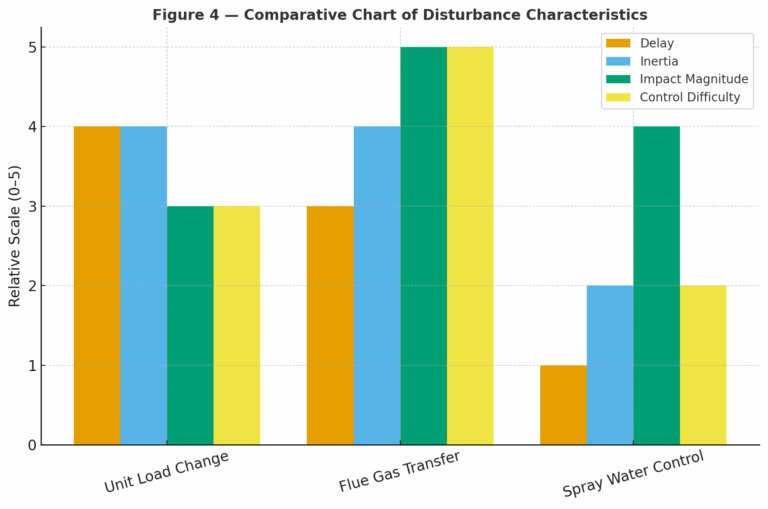

| Disturbance Source | Delay Characteristic | Inertia | Impact Magnitude | Control Difficulty |

|---|---|---|---|---|

| Unit Load Change | Large delay | Large | Medium to High | Medium |

| Flue Gas Heat Transfer | Medium to large delay | Large | High | High (uncertain) |

| Desuperheating Water Flow | Small delay | Medium | Direct & High | Low (but efficiency affected) |

4. Control Strategies

Feedforward + Cascade Control:

Load-related disturbances are better managed through feedforward compensation or cascade structures.Differential Action for Inertia:

For disturbances with large inertia, differential action in controllers can improve responsiveness.Coefficient Weighting:

Each disturbance should be scaled by a weighting coefficient to equalize their contribution in auxiliary control loops.

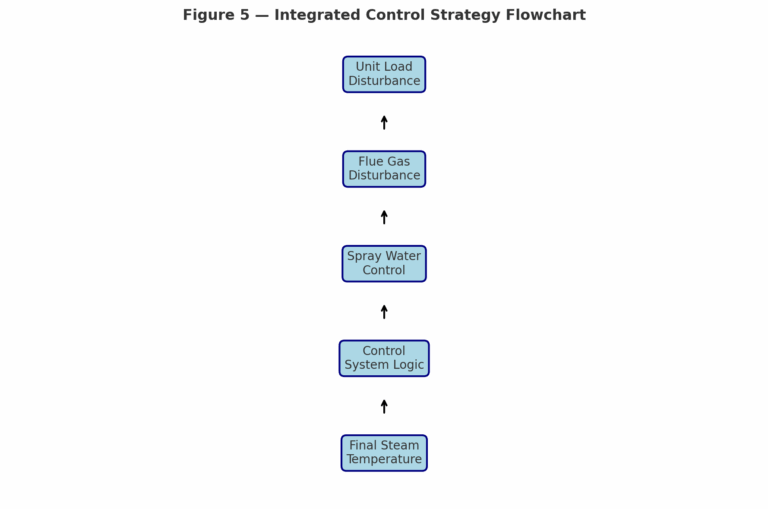

5. Conclusion

Steam temperature control is inherently complex due to the diverse and dynamic nature of disturbances. Among all, unit load fluctuation, flue gas heat transfer, and desuperheating water flow are the most influential.

Load changes introduce delayed but strong effects.

Flue gas disturbances are highly uncertain and the most challenging to handle.

Spray water adjustment provides fast correction but may compromise thermal efficiency.

An effective control system must therefore combine feedforward, cascade, and differential control, supported by proper design margins in desuperheating systems. With this integrated approach, stable steam temperature regulation and higher efficiency can be achieved.