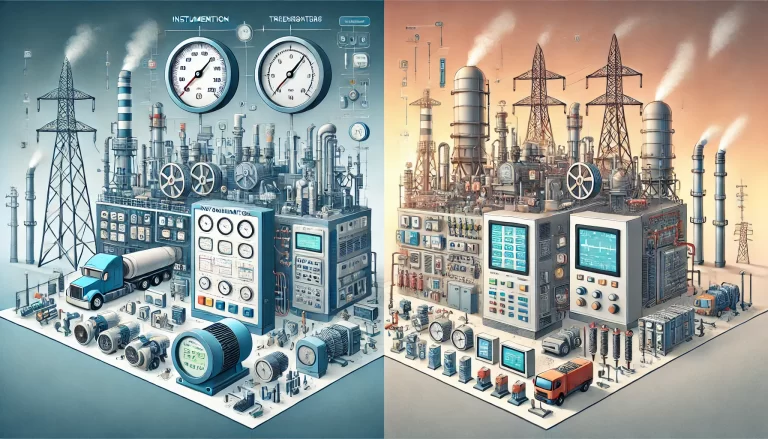

Instrumentation and electrical systems can be differentiated from the following aspects:

1. Definitions and Functions

Instrumentation:

- Definition: Refers to devices or systems used to measure, display, control, and record physical quantities such as temperature, pressure, flow, and liquid levels.

- Function: Primarily focused on the precise detection and monitoring of various physical quantities to provide accurate data support for production processes. This enables operators to make decisions and control operations. For example, a temperature instrument can measure real-time temperature changes in a production process and display the temperature values. If the temperature exceeds a set range, it can also issue an alarm signal.

Electrical Systems:

- Definition: Primarily involves the generation, transmission, distribution, and usage of electrical energy, as well as the associated technologies and equipment.

- Function: Encompasses power generation, power transformation, transmission, distribution, and control of electrical equipment. For example, a generator converts mechanical energy into electrical energy, a transformer adjusts voltage levels for efficient power transmission, and an electric motor converts electrical energy into mechanical energy to drive various machines.

2. Equipment and System Components

Instrumentation:

- Components: Typically composed of sensors, transmitters, displays, and controllers. Sensors detect physical quantities and convert them into electrical or other transmittable signals. Transmitters amplify, convert, or process these signals to meet standard output requirements. Displays present measurement results, and controllers perform automatic control or send control signals based on the measurements.

- System Characteristics: Instrumentation systems are generally complex and require highly accurate measurements and stable signal transmission. These systems are sensitive to environmental factors like temperature, humidity, and vibration. For instance, a pressure transmitter must accurately measure pressure changes in harsh industrial environments and transmit the signal stably to the control system.

Electrical Systems:

- Components: Includes generators, transformers, motors, switchgear, cables, etc. Generators are the source of electrical energy, transformers adjust voltages, motors are devices that use electrical energy, switchgear controls circuits, and cables transmit electrical energy.

- System Characteristics: Electrical systems usually involve high voltages and large currents, with stringent safety and reliability requirements. For instance, high-voltage transmission lines must withstand high voltages and currents while ensuring the safety of personnel and equipment.

3. Application Fields

Instrumentation:

- Industrial Applications: Widely used in chemical, petroleum, pharmaceutical, food, and environmental protection industries, as well as in laboratories and research institutions. In these fields, instrumentation is used to monitor and control various parameters during production, ensuring the safety, stability, and efficiency of the process. For example, in chemical production, various instruments control temperature, pressure, and flow to ensure smooth chemical reactions.

- Residential Applications: Instruments are also used in households, such as water meters, electricity meters, and gas meters, to measure and display energy consumption.

Electrical Systems:

- Industrial Applications: Primarily used in power systems, industrial production, transportation, and building construction. In power systems, electrical equipment is involved in every step from power generation to power consumption. In industrial production, electrical equipment such as motors and transformers are critical components. In transportation, electrical systems power trains, subways, and electric vehicles. In buildings, electrical systems control lighting, elevators, air conditioning, and other equipment.

4. Professional Knowledge and Skills

Instrumentation:

- Requires knowledge of physics, chemistry, electronics, and automatic control technologies. Professionals must understand the working principles of various sensors, signal processing technologies, and methods for calibrating and adjusting instruments. For example, an instrumentation engineer must know the properties of temperature sensors like thermocouples and thermistors, and have skills in installation, maintenance, and troubleshooting.

- Strong data analysis and processing skills are essential to analyze and judge measurement data, providing optimization suggestions for production processes. Communication and teamwork skills are also important for collaborating with process engineers and operators to solve production problems.

Electrical Systems:

- Requires knowledge of circuit theory, electromechanics, power electronics, and high-voltage technologies. Engineers must understand the working principles, operational characteristics, and maintenance methods of electrical equipment such as generators, transformers, and motors. For example, an electrical engineer must know how to start, speed control, and brake motors, as well as skills in installation, adjustment, and fault diagnosis.

- Electrical engineers need strong design and calculation skills to perform electrical system design, calculation, and equipment selection. Additionally, a high awareness of safety and compliance with operational standards are crucial to ensuring the safe operation of electrical equipment.

Summary: Distinctions Between Instrumentation and Electrical Systems

Instrumentation and electrical systems differ in several key aspects:

Definitions and Functions:

- Instrumentation focuses on measuring, monitoring, and controlling physical quantities such as temperature and pressure, providing data for operational decision-making.

- Electrical Systems involve generating, transmitting, and using electrical energy, including power generation, distribution, and driving mechanical equipment.

Components:

- Instrumentation includes sensors, transmitters, displays, and controllers, and is designed for accurate measurement and stable signal transmission.

- Electrical Systems consist of generators, transformers, motors, and cables, designed to handle high voltage and current, ensuring safety and reliability.

Applications:

- Instrumentation is widely used in industrial processes (e.g., chemical, pharmaceutical, and environmental sectors) and residential areas (e.g., water, electricity, and gas meters).

- Electrical Systems are critical in power systems, industrial production, transportation, and building infrastructure.

Knowledge and Skills:

- Instrumentation requires expertise in sensors, electronics, and data analysis, while collaboration with other engineers is essential.

- Electrical Systems demand knowledge of circuit theory, high-voltage technologies, and safety standards, with strong design and calculation abilities for system management.

Both fields are essential for industrial and residential functions but serve different purposes and require distinct technical expertise