1. Introduction

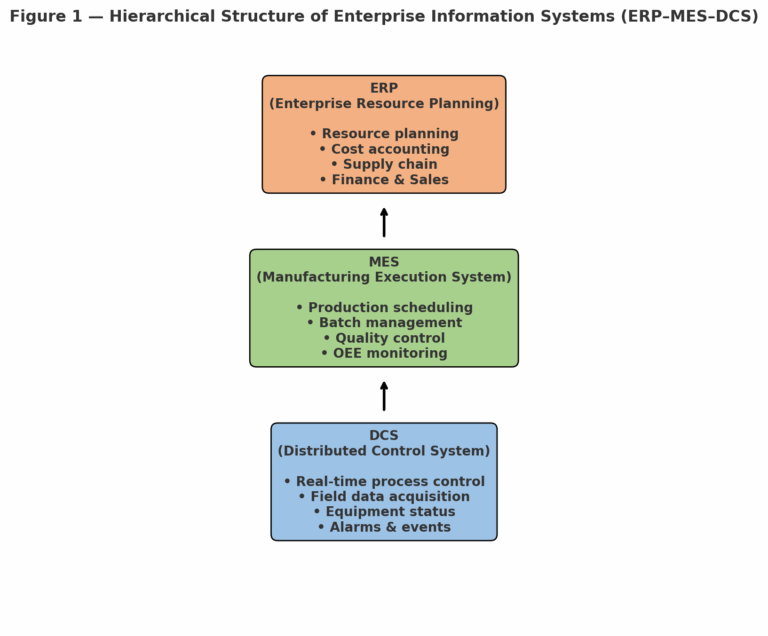

In modern manufacturing enterprises, the integration of Distributed Control Systems (DCS) and Enterprise Resource Planning (ERP) systems is a cornerstone for digitalization and smart manufacturing. While DCS focuses on real-time process monitoring and control at the plant floor, ERP emphasizes resource planning, scheduling, and cost management at the enterprise level.

Bridging these two systems enables seamless data flow, turning raw operational data into actionable business insights.

2. Why ERP Needs Data from DCS

Production Transparency – ERP requires real-time visibility of production progress to align scheduling plans with shop-floor execution.

Operational Optimization – Integrating field data allows ERP to optimize production schedules, improve equipment utilization, and identify bottlenecks.

Integrated Data Management – ERP combines material, production, and energy data for cost accounting, quality tracking, and carbon footprint management.

Eliminating Data Silos – Without integration, DCS data may remain isolated and underutilized, preventing enterprises from leveraging its full value.

3. Key Data Categories ERP Should Acquire from DCS

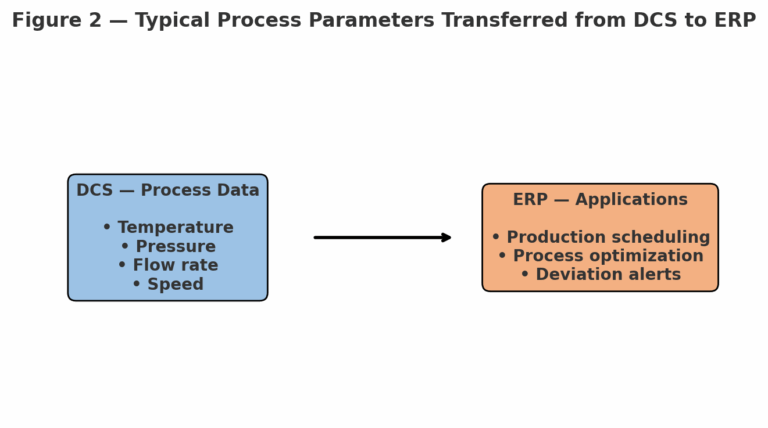

3.1 Real-time Process Data

Typical parameters: temperature, pressure, speed, and flow rate.

Application: production scheduling optimization, process deviation detection.

Example: variations in reboiler temperature can directly indicate abnormal unit operation.

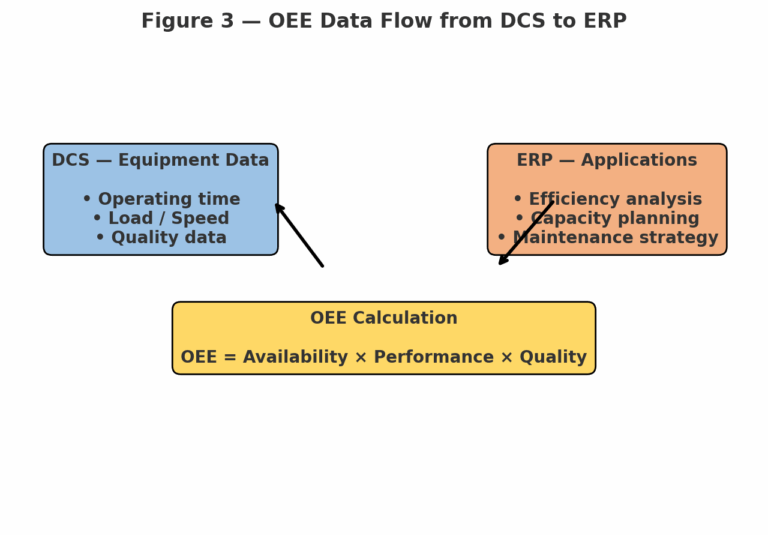

3.2 Equipment and Production Line Status

Information: machine start/stop, operating load, mode selection, fault alarms.

Key KPI: OEE (Overall Equipment Effectiveness) — time, performance, and quality.

ERP Use: core reference for equipment efficiency and availability management.

3.3 Alarm and Event Records

Data: trigger time, alarm severity, acknowledgment status.

ERP Use: root cause analysis, preventive maintenance planning, quality issue traceability.

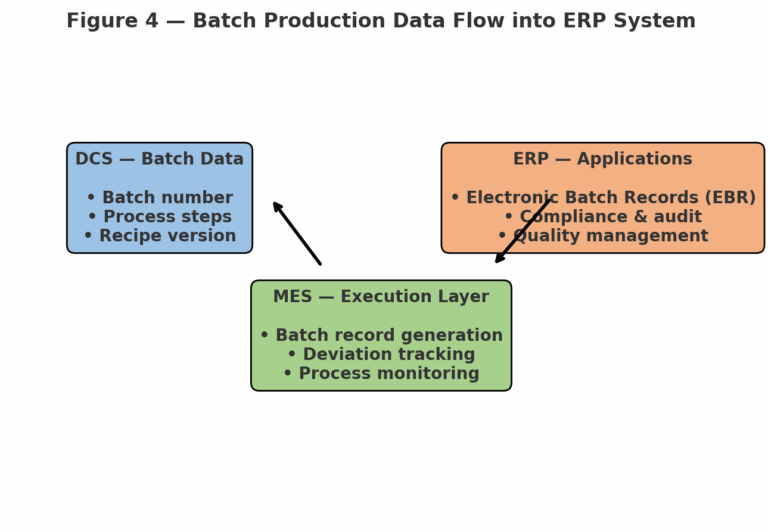

3.4 Batch and Recipe Information

Batch number, process steps, recipe version.

ERP Use: generation of Electronic Batch Records (EBR), process deviation control, full production traceability.

3.5 Production Output and Energy Consumption

Data: per-shift output, defective quantities, energy usage (electricity, water, steam).

ERP Use: production plan calibration, cost allocation, carbon footprint accounting.

3.6 Online Quality Monitoring Data

Parameters: pH value, viscosity, concentration, etc.

ERP Use: real-time support for quality management, enabling early detection and control of issues.

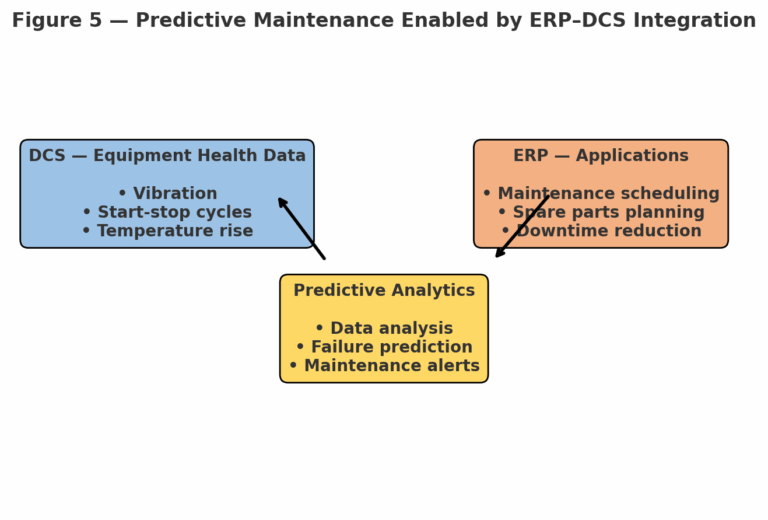

3.7 Equipment Health and Maintenance Data

Metrics: vibration, number of start-stops, temperature rise.

ERP Use: predictive maintenance, life-cycle extension, avoiding downtime losses.

4. Business Value of ERP–DCS Integration

Enhanced production transparency

Optimized resource allocation and cost reduction

Improved equipment reliability and predictive maintenance

Stronger quality assurance and traceability

Data-driven sustainability and carbon management

5. Future Outlook

As digital transformation deepens, the ERP–DCS interface will evolve from simple data transfer to intelligent analytics and decision support.

AI and machine learning will analyze DCS data in ERP for predictive scheduling and anomaly detection.

Industrial IoT platforms will further expand data connectivity across systems.

Carbon accounting and ESG compliance will increasingly rely on integrated production and energy data.

6. Conclusion

By connecting DCS with ERP, enterprises can transform “shop-floor data” into “business intelligence.” This integration empowers management decisions, drives efficiency, and paves the way for truly smart operations.