A differential pressure (DP) flow meter is a widely used flow measurement instrument across various industries, including oil and gas, chemical processing, and power generation. It is particularly effective for measuring the flow of gases and liquids, including corrosive gases, when designed with appropriate materials. This type of flow meter operates based on Bernoulli’s principle, which relates the velocity of fluid flow to the difference in pressure created by an obstruction within the flow path.

Working Principle

The differential pressure flow meter measures flow by introducing a constriction into the flow stream, causing a pressure drop. This pressure difference, known as the differential pressure, is proportional to the square of the flow rate. By measuring the pressure difference upstream and downstream of the obstruction, the flow rate can be calculated.

There are three common types of DP flow meter elements used to create this pressure differential:

- Orifice Plate: A thin plate with a hole in the center that restricts the flow.

- Venturi Tube: A tube with a gradually narrowing throat followed by a gradual expansion to minimize energy losses.

- Flow Nozzle: A shaped nozzle that accelerates the fluid and creates a pressure drop, commonly used for high-velocity flow.

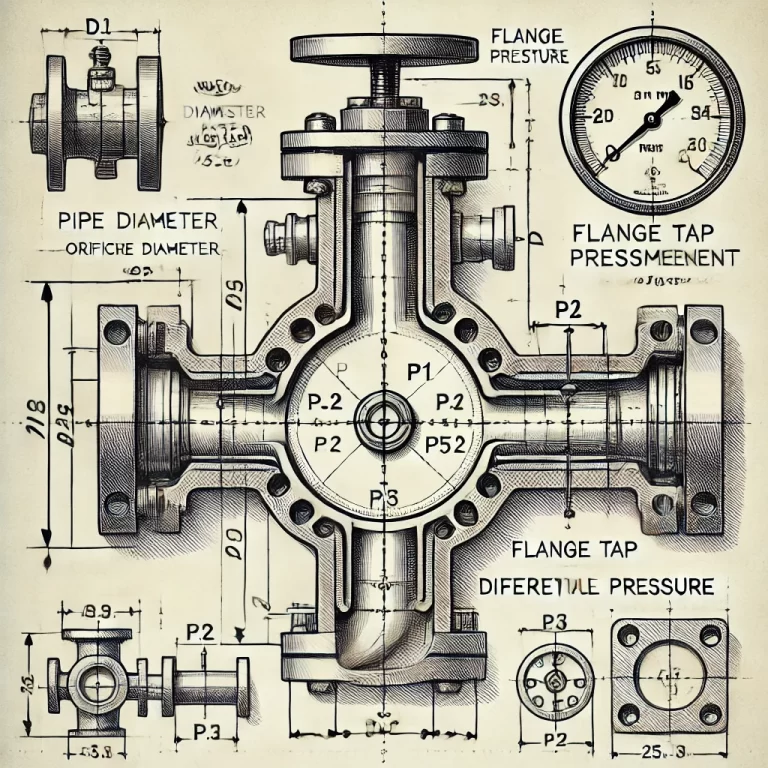

Components of a Differential Pressure Flow Meter

- Primary Element: The flow element that creates the differential pressure, such as an orifice plate, Venturi tube, or flow nozzle.

- Secondary Element: The component that measures the differential pressure and converts it into a flow rate. It includes pressure transmitters and differential pressure sensors.

- Impulse Piping: Small-bore piping that connects the pressure taps on the primary element to the differential pressure transmitter, ensuring accurate measurement.

- Differential Pressure Transmitter: The device that senses the difference in pressure between two points and converts this differential into a standardized signal for monitoring and control.

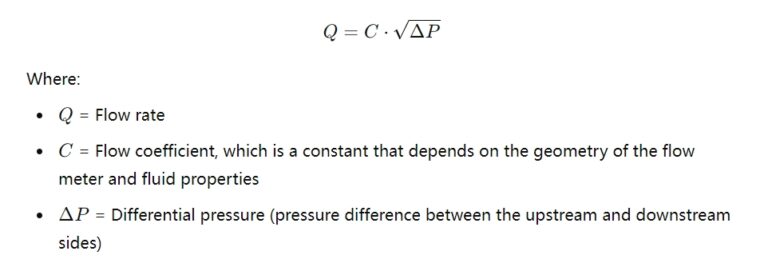

Mathematical Model

The flow rate (Q) in a differential pressure flow meter can be calculated using the following relationship:

This equation demonstrates that the flow rate is proportional to the square root of the differential pressure, making it necessary to have precise measurements of both pressure and flow conditions to ensure accuracy.

Advantages of Differential Pressure Flow Meters

- Wide Applicability: DP flow meters can be used to measure the flow of a wide range of fluids, including gases, liquids, and steam, making them versatile for many applications.

- Proven Technology: DP flow meters are based on well-understood fluid dynamics principles and have been in use for over a century. They are widely accepted and standardized in many industries.

- No Moving Parts: Unlike some other types of flow meters, DP flow meters do not have any moving mechanical components, which enhances their durability and reliability.

- High Temperature and Pressure Capability: They can be designed to withstand extreme conditions, making them suitable for use in harsh environments, such as refineries, power plants, and chemical industries.

- Material Compatibility: For corrosive gases and liquids, DP flow meters can be constructed using corrosion-resistant materials, such as stainless steel, Hastelloy, or other specialty alloys, to ensure long-term performance without degradation.

Applications in Corrosive Gas Measurement

In industrial settings where corrosive gases such as chlorine, hydrogen sulfide, or sulfur dioxide need to be measured, a differential pressure flow meter is often chosen due to its ability to handle high-pressure and high-temperature environments. When dealing with such corrosive gases, the choice of materials is critical. For instance, the primary element can be constructed from Hastelloy or lined with PTFE (polytetrafluoroethylene) to resist chemical corrosion. Additionally, the impulse piping and pressure transmitters must also be made of or coated with corrosion-resistant materials to prevent deterioration.

In gas applications, a Venturi tube is often preferred over an orifice plate because it minimizes energy losses and reduces the wear caused by abrasive gases. Moreover, the Venturi design ensures less permanent pressure drop, making it more energy efficient in long-term operation.

Limitations and Challenges

While DP flow meters are versatile and widely used, they also have certain limitations:

- Accuracy Depends on Installation: Correct installation, including proper alignment and positioning of the primary element, is crucial for accurate measurements. Misalignment can cause errors in the flow rate readings.

- Pressure Loss: Even though a Venturi tube can minimize pressure losses, DP flow meters inherently cause a pressure drop across the primary element. This can lead to energy losses, especially in large systems.

- Susceptibility to Clogging: In applications where the fluid contains particulate matter, debris may accumulate in the orifice or nozzles, causing clogging and requiring regular maintenance.

- Nonlinear Relationship: Since the flow rate is proportional to the square root of the differential pressure, changes in flow can lead to significant variations in the pressure signal, which requires careful calibration and compensation.

- Temperature and Density Sensitivity: Changes in the gas temperature and density can affect the accuracy of the differential pressure measurement. Therefore, compensating for temperature and pressure variations is essential when dealing with gases.

Installation Considerations

For optimal performance, several factors should be considered when installing a differential pressure flow meter:

- Straight Pipe Requirements: The meter needs sufficient straight pipe upstream and downstream of the primary element to ensure a fully developed flow profile. This minimizes measurement errors due to turbulence or flow disturbances.

- Correct Sizing: Oversizing or undersizing the meter can lead to inaccurate measurements, so it’s crucial to select the appropriate size for the expected flow rate.

- Temperature Compensation: In gas flow measurements, temperature compensation is necessary to account for the changes in gas density, which can affect the flow rate calculation.

Conclusion

Differential pressure flow meters are reliable, versatile instruments that are widely used across multiple industries for measuring the flow of both liquids and gases, including corrosive gases. Their ability to withstand harsh environments and extreme conditions makes them an ideal choice for many applications. However, like any flow measurement technology, they require careful installation, material selection, and maintenance to ensure long-term accuracy and performance, especially in environments involving corrosive gases. With the right design considerations, DP flow meters can provide accurate and reliable flow measurements, even in the most challenging industrial environments.