1. Introduction

NAMUR (Normenarbeitsgemeinschaft für Mess- und Regeltechnik in der Chemischen Industrie) is a leading German user association that develops important guidelines for process automation. Among its many recommendations, NE 43 and NE 107 are particularly influential in device diagnostics and health monitoring.

Although both aim to improve reliability and safety in process industries, they focus on different layers of information:

NE 43 standardizes analog signal behavior (4–20 mA) to indicate failure conditions.

NE 107 defines a digital framework for communicating device health states.

2. Objectives and Background

NAMUR NE 43

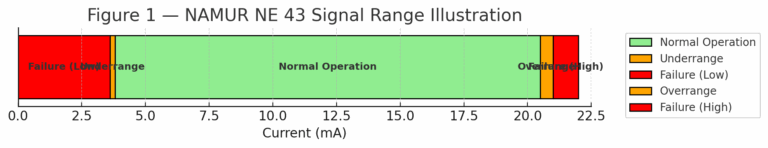

Scope: Specifies how field devices should use the 4–20 mA analog signal to represent operating and fault conditions.

Purpose: Ensure consistent fault indication via current values so that control systems can automatically detect failures and trigger alarms.

Typical Ranges:

Table 1 — NAMUR NE 43 Current Signal Ranges

| Current Range (mA) | Meaning | Typical Cause |

|---|---|---|

| 3.8 – 20.5 | Normal operating range | Valid measurement signal |

| < 3.6 | Fault – sensor failure / open loop | Broken wire, device fault |

| 20.0 – 20.5 | Normal over-range | Measurement beyond upper span |

| > 21.0 | Fault – overrange / short circuit | Shorted wiring, severe failure |

NAMUR NE 107

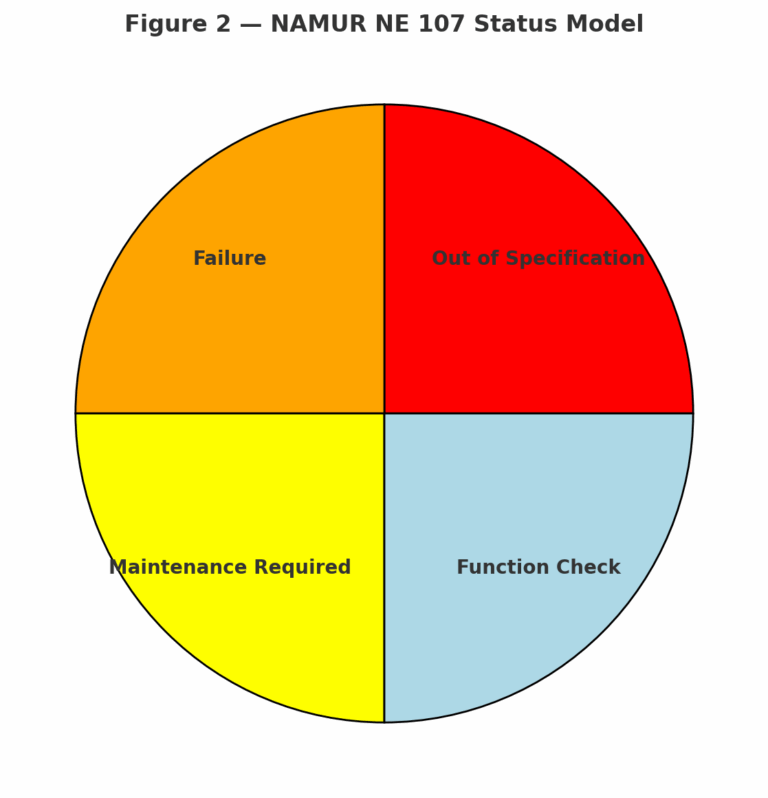

Scope: Defines a uniform model for device status signaling in digital communication (e.g., fieldbus, HART, Profibus, Foundation Fieldbus).

Purpose: Provide standardized diagnostic categories so operators can clearly understand device conditions.

Four Standard Status Signals:

Failure – Device is malfunctioning, measurement cannot be trusted.

Out of Specification – Process exceeds device’s design limits.

Maintenance Required – Device is still operating, but needs service soon.

Function Check – Device is under test or maintenance; signal should be temporarily ignored.

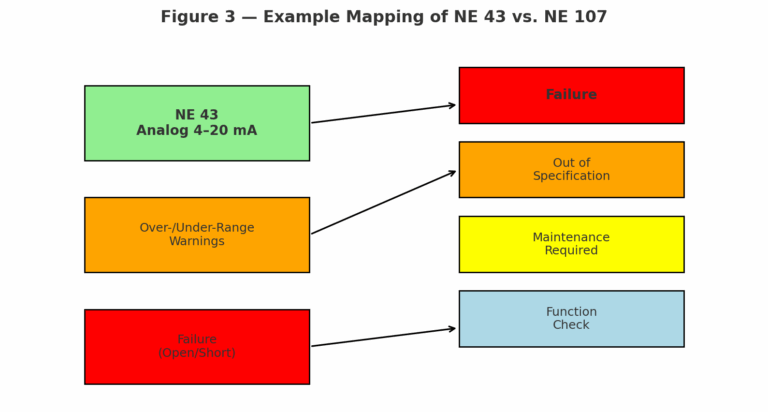

3. Comparison of NE 43 and NE 107

Table 2 — Comparison of NAMUR NE 43 vs. NE 107

| Aspect | NAMUR NE 43 | NAMUR NE 107 |

|---|---|---|

| Signal Type | Analog (4–20 mA) | Digital (fieldbus / HART / Profibus) |

| Information Depth | Basic fault indication (open/short) | Detailed diagnostics (4 categories) |

| Focus | Hardware failure detection | Device health & maintenance strategy |

| Typical Devices | Classic pressure, temperature, flow | Intelligent transmitters, smart valves |

| Application Domain | Legacy analog systems | Modern digital/asset management systems |

4. Application Examples

Pressure Transmitter (Analog)

Normal range: 4–20 mA proportional to 0–100% pressure.

If signal drops below 3.6 mA, the system detects a failure according to NE 43.

Quick fault identification allows operators to take corrective action.

Temperature Sensor (Analog with Over-Range)

Outputs 20 mA at maximum temperature.

If process exceeds range, device may send 21 mA, triggering NE 43 over-range warning.

In contrast, an NE 107-enabled digital device would report “Out of Specification” or “Over-Temperature Warning.”

Smart Digital Transmitters

Equipped with self-diagnostics.

Communicate “Maintenance Required” (e.g., sensor drift, aging) before actual failure.

Enable predictive maintenance and reduce unplanned downtime.

5. Recommendations

Use NE 43 for legacy systems and devices that primarily communicate via 4–20 mA signals. It ensures a simple but reliable method for failure detection.

Adopt NE 107 in modern plants with intelligent field devices and digital communication networks, where advanced diagnostics and predictive maintenance are required.

Hybrid Approach: Many facilities operate mixed systems; combining NE 43 fault detection with NE 107 diagnostic reporting provides the most comprehensive coverage.

6. Conclusion

NE 43 and NE 107 serve complementary purposes in industrial automation:

NE 43 ensures consistent analog fault signaling.

NE 107 provides richer, standardized device health information for smart maintenance strategies.

When selecting between them, consider the type of device, communication system, and plant automation level. In traditional analog systems, NE 43 remains indispensable; in digitalized environments, NE 107 delivers higher operational intelligence.