When dealing with electrical systems, it is crucial to understand the differences between electric wires and cables, as well as how their models are classified. These factors influence their usage, performance, and suitability for different environments.

Differences Between Electric Wires and Cables

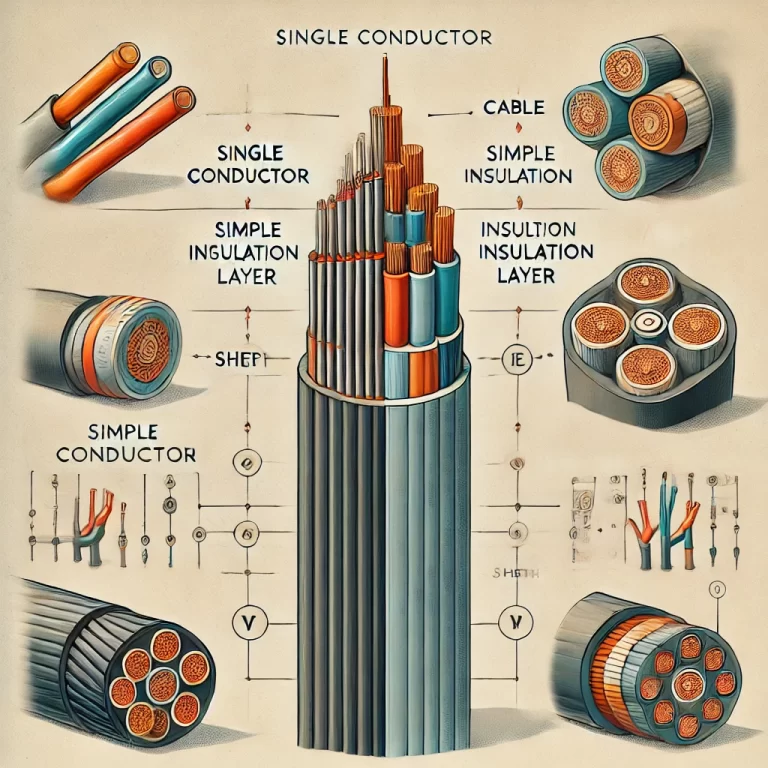

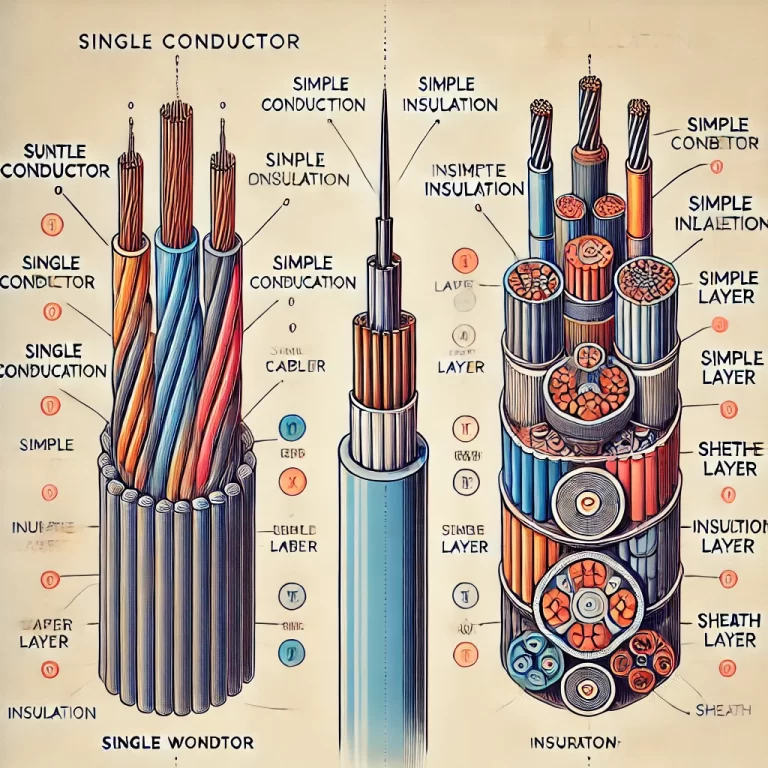

Structure:

- Electric Wires: Typically consist of one or a few flexible conductors with a relatively thin layer of insulation. The cross-sectional area is generally smaller, making them ideal for transmitting low voltage or signals.

- Cables: Made of multiple conductors encased in several layers of insulation, shielding, and protective materials. Their larger cross-sectional area provides better insulation and interference resistance, making them suitable for long-distance and high-current transmission.

Usage:

- Electric Wires: Mostly used for indoor wiring, household appliances, and electronic devices, primarily for low-voltage, low-current transmission.

- Cables: Widely used in power systems, communication networks, and industrial equipment, handling larger currents and higher voltages, often over long distances.

Performance:

- Electric Wires: They are typically simpler in design, more flexible, and are used in daily applications but have a lower capacity for power transmission.

- Cables: With stronger durability, they have additional protective layers to withstand high temperatures, corrosion, and other harsh environmental factors, making them suitable for industrial and outdoor use.

Model Codes and Their Meanings

Electrical wires and cables come in various models, which are represented by combinations of letters and numbers. Each letter or number signifies specific features such as material, structure, and application. Below are some common letter codes and examples of cable types:

1. Common Letter Meanings

- V: Polyvinyl chloride (PVC) insulation. For example, BV represents a copper conductor with PVC insulation.

- Y: Polyethylene insulation. BY denotes copper wire with polyethylene insulation.

- B: Represents a general wire, usually for fixed wiring.

- T: Copper conductor, e.g., BT for copper core cables.

- L: Aluminum conductor, e.g., BL for aluminum core cables.

- R: Flexible wire or cable, used in situations that require flexibility.

- K: Control cables, used in automatic control systems for signal transmission.

- Z: Flame-retardant cables, such as ZR-BV for flame-retardant PVC-insulated copper wire.

- NH: Fire-resistant cables, e.g., NH-BV, which means fire-resistant PVC-insulated copper wire.

2. Common Model Examples

- BV: Copper conductor with PVC insulation, suitable for fixed wiring, commonly used in residential or building wiring.

- BVV: Copper conductor with PVC insulation and sheath, offering an extra layer of protection for fixed installations.

- RV: Flexible copper wire with PVC insulation, suitable for installations requiring flexibility.

- YJV: Copper conductor with cross-linked polyethylene (XLPE) insulation and PVC sheath, used in power transmission systems.

- KVV: Copper conductor control cable with PVC insulation and sheath, used for automation and control systems.

- VV: PVC insulated and sheathed power cable, used for power transmission and distribution.

- YJV22: Copper conductor, XLPE insulation, steel tape armored with PVC sheath, designed for underground installations with higher mechanical protection.

3. Numbers and Their Significance

- The numbers in cable models typically represent the number of cores (wires) and the cross-sectional area of each core. For example:

- BV 2.5: Refers to a copper wire with a cross-sectional area of 2.5 square millimeters and PVC insulation.

- YJV 3×16: Denotes a power cable with three cores, each with a cross-sectional area of 16 square millimeters.

4. Special Models

- ZC-YJV: Low-smoke, halogen-free, flame-retardant XLPE insulated and PVC sheathed cable, used in environments with strict flame retardancy requirements.

- ZR-KVV: Flame-retardant control cable, ideal for use in automated control systems with flame resistance demands.

Conclusion

Electric wires are more suitable for lightweight applications, while cables are designed for industrial use, long-distance transmission, or environments requiring greater protection. The model codes, a combination of letters and numbers, indicate specific characteristics such as conductor material, insulation type, and flame retardancy, helping to select the appropriate wire or cable for different applications. Understanding these model codes is essential for making informed decisions in electrical installations and ensuring safety and efficiency.