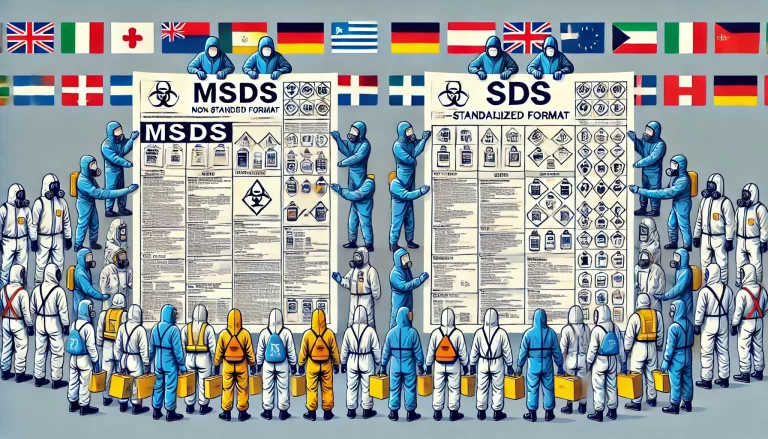

When dealing with hazardous materials, ensuring safety is paramount. To facilitate this, safety data sheets are essential tools, providing vital information on how to handle, store, and dispose of chemicals safely. Over time, these sheets have been standardized and evolved from the Material Safety Data Sheet (MSDS) to the Safety Data Sheet (SDS). Though MSDS and SDS share the same purpose, there are significant differences between the two, especially in terms of format, standardization, and international applicability.

1. MSDS vs SDS: Terminology and Historical Context

MSDS (Material Safety Data Sheet): Historically, the MSDS was widely used across various industries, laboratories, and sectors. The term refers to a document that provides critical information about a substance’s physical, chemical, and toxicological properties. It was developed to help workers and first responders understand the potential hazards of chemicals and how to handle them safely.

SDS (Safety Data Sheet): In 2003, the United Nations introduced the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) to standardize the classification and labeling of chemicals worldwide. As part of this system, MSDS was replaced by the SDS format to create a more consistent and globally recognized system for hazard communication.

2. Standardization and Format: MSDS vs SDS

The most significant difference between MSDS and SDS lies in their format and structure.

MSDS: The content and structure of MSDS were not standardized globally. This meant that each country, or even individual companies, might format the MSDS differently. As a result, MSDS documents could vary widely in terms of the amount and type of information they provided, which sometimes led to confusion when interpreting safety instructions across different regions.

SDS: With the introduction of GHS, SDS has become the internationally accepted format for communicating safety information about hazardous materials. SDS is structured into 16 standardized sections, ensuring that the information is organized consistently across different countries and industries. These sections cover key details such as:

- Identification of the substance or mixture

- Hazard identification

- Composition/information on ingredients

- First-aid measures

- Firefighting measures

- Accidental release measures

- Handling and storage

- Exposure controls/personal protection

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

- Ecological information (non-mandatory for some countries)

- Disposal considerations

- Transport information

- Regulatory information

- Other information

This standardized format ensures that no matter where a chemical is used or manufactured, the safety information remains consistent, making it easier for workers, responders, and regulators to understand the necessary precautions.

3. Legislation and Global Adoption

MSDS: Before GHS, MSDS formats were developed according to local or national regulations, leading to variations in the quality and comprehensiveness of the information. For example, the United States had its own regulations under OSHA’s Hazard Communication Standard, while the European Union and other regions had different requirements. This lack of uniformity made it difficult to ensure that workers in different parts of the world received the same level of protection.

SDS: GHS, on the other hand, has been adopted by many countries and regions, including the United States, European Union, Canada, Australia, and others. The SDS format is now a global standard, and most major economies require that chemicals sold or imported into their markets come with an SDS that conforms to GHS guidelines. This not only ensures consistency but also simplifies compliance for companies operating in multiple regions.

4. Content and Information Quality

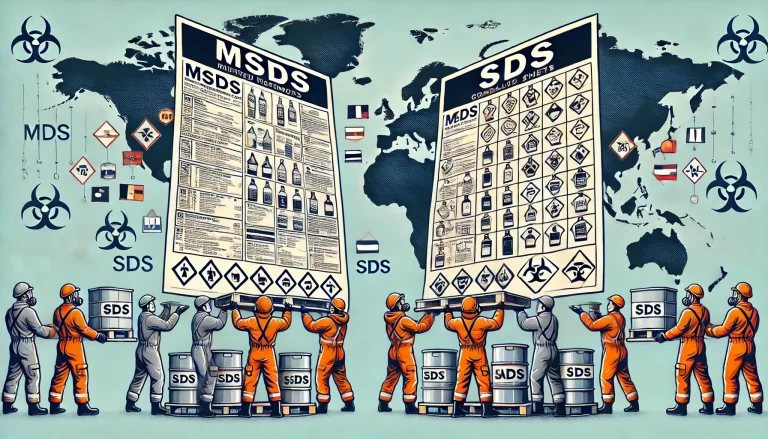

MSDS: Since there was no global standard for MSDS, the level of detail could vary from one document to another. Some MSDS documents might have extensive information about handling and storage, while others might provide limited details. This inconsistency sometimes made it difficult to rely on MSDS alone for complete hazard communication, especially in international settings.

SDS: The SDS, with its globally standardized 16-section format, ensures that all necessary information is included, and nothing critical is left out. For example, SDS documents must include detailed hazard identification, including the classification of the substance or mixture, as well as all precautionary statements. This level of detail helps users understand the risks involved and take appropriate safety measures.

5. International Compatibility and Compliance

MSDS: One of the challenges with MSDS was that its format often didn’t comply with international regulations. As companies began operating more globally, they faced the need to create multiple versions of MSDS to meet the requirements of different countries.

SDS: SDS addresses this issue by providing a unified, global standard. By using the GHS system, companies can create one version of the SDS that complies with most international regulations. This simplification not only reduces administrative burden but also improves safety by ensuring that safety information is accurate and consistent, no matter where the chemical is being used.

6. Language and Accessibility

MSDS: Since MSDS were often locally produced, they might only be available in the language of the country where the product was manufactured or sold. This posed a challenge for multinational organizations where employees might speak different languages.

SDS: Under GHS, SDS is required to be available in multiple languages depending on the country’s requirements. For example, in the European Union, SDS must be provided in the official language(s) of the member state(s) where the chemical is being used. This multilingual requirement makes SDS more accessible to workers around the world.

7. Key Benefits of Transitioning from MSDS to SDS

The transition from MSDS to SDS under the GHS system offers several key benefits:

- Consistency: With a standardized 16-section format, safety information is clear and consistent across the globe.

- International Compliance: SDS meets international requirements, making it easier for companies to comply with global regulations.

- Enhanced Safety: SDS provides more comprehensive and detailed information than many older MSDS documents, helping users better understand the risks and safety precautions associated with chemicals.

- Improved Communication: The availability of SDS in multiple languages ensures that workers can access safety information in their native language, improving understanding and compliance.

Conclusion

While the Material Safety Data Sheet (MSDS) and Safety Data Sheet (SDS) both aim to provide vital safety information for handling hazardous chemicals, the introduction of SDS under the Globally Harmonized System (GHS) marks a significant improvement in standardization, clarity, and international compatibility.

With its uniform 16-section format and global adoption, SDS provides a more reliable and accessible tool for ensuring safety in industries and laboratories worldwide.