Executive summary

Most accuracy problems come down to four buckets: installation, fluid properties, device faults, and external interference. Use the triage table below, then follow the corrective actions.

1) Rapid triage (symptom → likely cause → how to check → fix)

| Symptom | Likely cause | How to check | Corrective action |

|---|---|---|---|

| Reading drifts / unstable | Not full pipe; air bubbles | Look for gurgling, intermittent zero; inspect upstream vents | Ensure full pipe; add air vent upstream; throttle valve downstream |

| Consistently high/low vs. reference | Wrong diameter/scale in converter | Compare converter setup vs. actual line size/flow range | Re-enter pipe ID, range; perform zero calibration (full pipe, no flow) |

| Intermittent spikes | Poor grounding / VFD noise | Measure ground loop; note proximity to VFDs/transformers | Separate protective grounds; ≤10 Ω; route cables away from noise sources |

| Near-zero on conductive service | Electrodes fouled | Inspect electrodes; look for scale/oil films | Clean with soft cloth or mild acid compatible with material |

| Output saturates at max | Flow exceeds range; wrong K-factor | Compare process flow vs. configured span | Increase range or use larger meter; correct configuration |

| Reading only at high flow | Low conductivity fluid | Check conductivity (>~5 µS/cm needed) | Switch technology (e.g., ultrasonic) or adjust process chemistry |

| Random dropouts | Coil/lead faults | Measure coil resistance (per datasheet, usually tens of Ω) | Repair wiring; replace sensor/coil if out of spec |

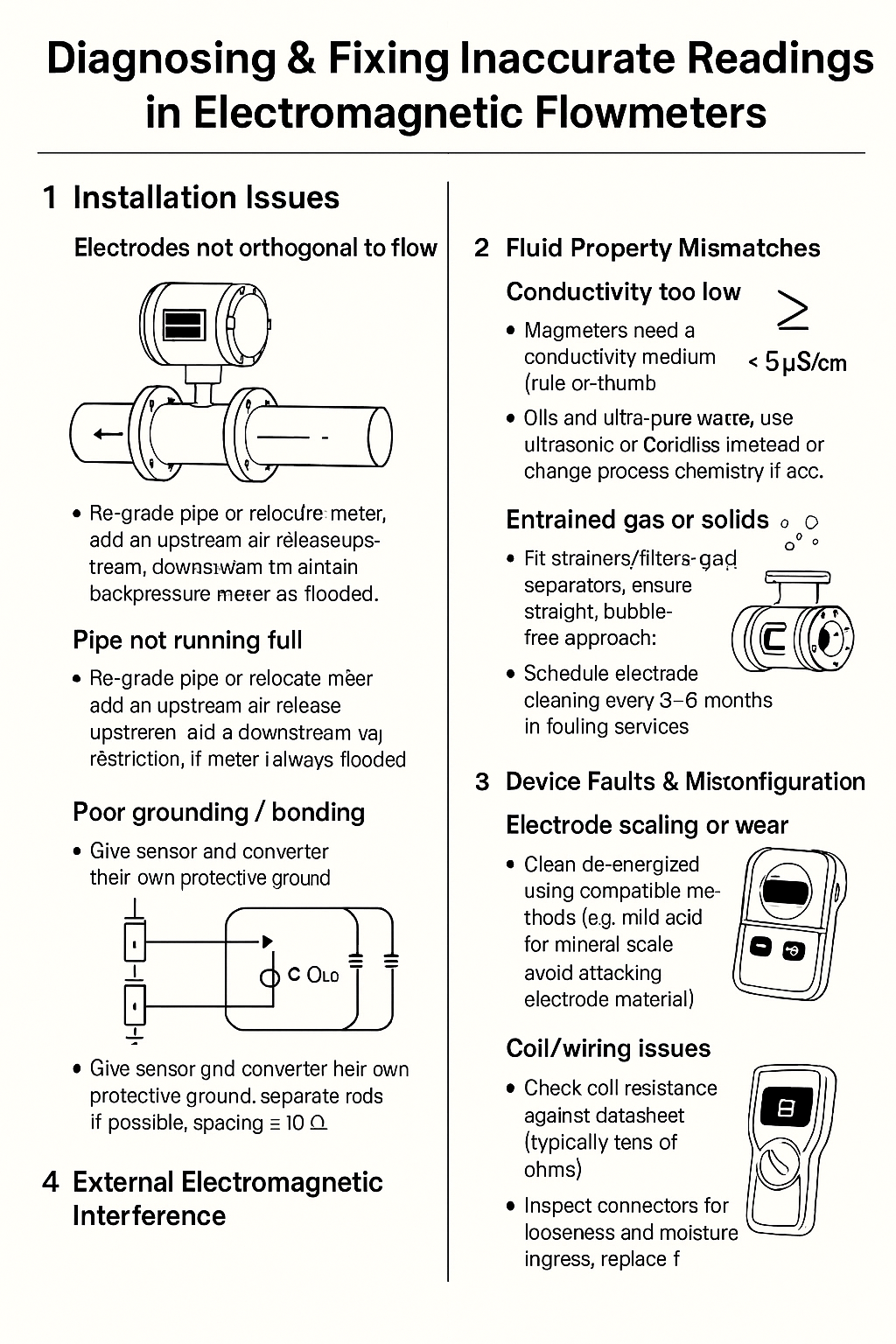

2) Installation issues (most common)

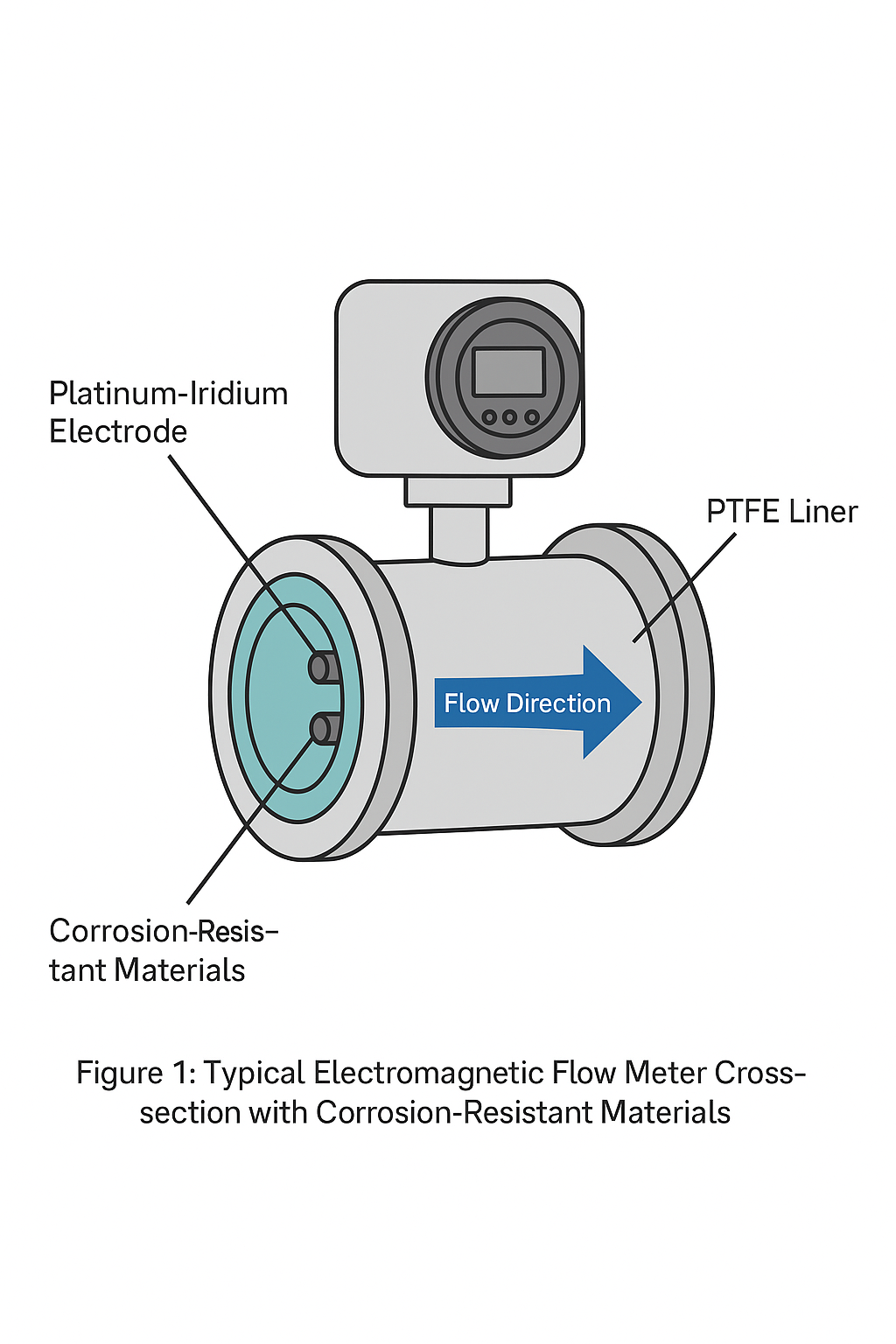

Electrodes not orthogonal to flow

Ensure the electrode axis is perpendicular to flow. On horizontal runs, keep electrodes on the horizontal centerline to avoid gas/slag accumulation. Re-align the body if needed.

Pipe not running full

Re-grade pipe or relocate meter; add upstream air release and a downstream restriction/valve to maintain backpressure so the meter is always flooded.

Poor grounding / bonding

Give the sensor and converter their own protective ground (separate rods if possible, spacing >5 m). Target ground resistance ≤10 Ω. Bond liners or grounding rings as specified.

3) Fluid property mismatches

Conductivity too low

Magmeters need a conductive medium (rule-of-thumb >~5 µS/cm). Oils and ultra-pure water may not work—use ultrasonic/Coriolis instead or change process chemistry if acceptable.

Entrained gas or solids

Fit strainers/filters and gas separators; ensure straight, bubble-free approach. Schedule electrode cleaning every 3–6 months in fouling services.

Excess viscosity / high velocity

For viscous media, use a larger bore to reduce velocity and shear layers; keep working velocity in the 20–80% of span sweet spot (typical max ≤ 10 m/s).

4) Device faults & misconfiguration

Electrode scaling or wear

Clean de-energized using compatible methods (e.g., mild acid for mineral scale; avoid attacking electrode material). Replace if pitted or eroded.

Wrong converter parameters

Verify: line size, range, outputs (pulse/4–20 mA/RS-485), pipe material/lining settings. Do a zero trim with the pipe full and static.

Coil/wiring issues

Check coil resistance (datasheet value, typically tens of ohms). Inspect connectors for looseness and moisture ingress; replace faulty parts.

5) External electromagnetic interference

Keep the meter/cables away from strong fields (VFDs, large motors/transformers). If relocation isn’t possible, use a grounded metallic shield enclosure and segregate signal cables from power. Maintain ≥2 m spacing where practical.

6) Commissioning & maintenance checklist

Before startup

✅ Straight run and orientation verified; electrodes on horizontal axis for horizontal lines

✅ Always-full condition ensured (vent upstream, valve downstream)

✅ Independent protective grounds installed (≤10 Ω), shield drain grounded at one end

✅ Converter parameters match nameplate and process (ID, range, output scaling)

✅ Noise sources identified; cable routing separated from power/VFD trunks

Routine care

🗓️ Inspect/clean electrodes every 3–6 months in fouling services

🗓️ Verify zero (full pipe, no flow) quarterly or after maintenance

🗓️ Periodically re-torque flanges and re-test ground resistance

Field test procedures (quick references)

Zero check — Full pipe, pumps off, valves closed. Output should be 0 within spec. Adjust zero if drifted.

Coil continuity — Isolate and measure coil resistance; compare to spec. Replace if out of range.

Noise isolation — Temporarily power from a clean circuit, bypass VFD, or run on UPS to see if noise disappears. If yes, improve shielding/grounding and cable segregation