The risk of dust explosions is a critical concern in industries where materials such as flour, wood, metal, or plastic powders are processed or handled. Many substances that may seem harmless can create explosive dust clouds under the right conditions. Properly identifying and assessing the combustible properties of dust in a facility is essential to preventing catastrophic incidents. This article outlines the comprehensive process for determining whether a specific dust constitutes a combustible hazard.

Step 1: Collecting Basic Information About the Dust

Before conducting tests or applying safety measures, it is crucial to gather initial data about the dust:

- Source of Dust: Identify whether the dust originates from raw materials, production processes (e.g., cutting, grinding, polishing), or by-products.

- Particle Size and Shape: Dust particles with diameters under 500 microns (0.5 mm) are more likely to be combustible due to their high surface area-to-volume ratio, which allows for rapid combustion.

- Moisture Content: Dust with high moisture content is less prone to ignition, though drying over time can increase combustibility.

- Chemical Composition: Organic materials (e.g., flour, sugar, or wood) are typically combustible. Some metal powders (like aluminum) or plastics also pose high explosion risks.

Step 2: Referencing Standards and Regulations

Assessing combustible dust hazards involves following established safety standards. Here are some key national and international frameworks:

China:

- GB 12476: Explosive atmospheres—protection for equipment used in environments with combustible dust.

- GB/T 15604: Definition and testing methods for combustible dusts.

International:

- IEC 60079: Electrical equipment standards for explosive atmospheres.

- NFPA 652: Fundamentals of combustible dust hazard management.

- ATEX Directive (EU): Requirements for equipment and protective systems in potentially explosive atmospheres.

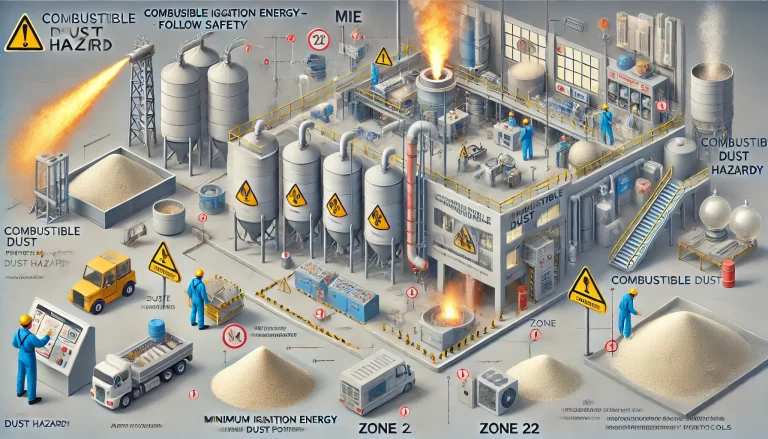

Step 3: Laboratory Testing for Combustibility

Laboratory tests are essential to determine whether the dust presents an explosion hazard. A specialized facility conducts these tests to provide the following key metrics:

Minimum Ignition Energy (MIE):

- Measures the minimum energy required to ignite a dust cloud under standard conditions.

- If the MIE is less than 10 millijoules (mJ), the dust is highly susceptible to ignition from small sparks or static discharge.

Explosion Limits:

- Lower Explosive Limit (LEL): The minimum dust concentration in air that can sustain an explosion.

- Upper Explosive Limit (UEL): The maximum concentration above which there is insufficient oxygen to support combustion.

Maximum Explosion Pressure (Pmax) and Explosion Severity (Kst):

- These metrics assess the intensity of the explosion if the dust ignites.

- Kst values classify the explosion severity:

- Kst = 0: Not explosible.

- Kst = 1–200: Low severity.

- Kst = 201–300: Medium severity.

- Kst > 300: High severity.

Step 4: Evaluating the Workplace Environment

Once the combustibility of the dust is determined, the next step is assessing how it interacts with the environment. A facility’s operational conditions and dust handling systems can significantly affect explosion risks.

- Dust Accumulation: Examine whether dust settles on surfaces, inside equipment, or within ventilation systems. Layers of dust can ignite under specific conditions.

- Air Circulation: Poor ventilation can allow dust to build up in enclosed spaces, increasing explosion risks.

- Ignition Sources: Identify potential ignition sources such as:

- Electrical equipment and wiring.

- Friction or sparks from machinery.

- Static electricity build-up.

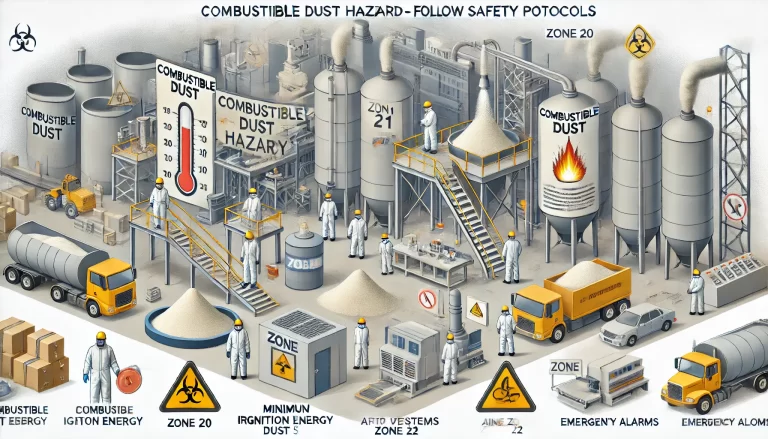

Step 5: Hazard Classification of the Area

Based on the risk analysis, the workplace may be divided into hazardous zones for dust:

- Zone 20: Areas where a cloud of combustible dust is present continuously or for long periods (e.g., inside silos).

- Zone 21: Areas where combustible dust clouds are likely to occur during normal operation.

- Zone 22: Areas where dust clouds are unlikely but still possible during abnormal conditions or maintenance.

Step 6: Implementing Control Measures

If the dust is confirmed to be combustible, proper control measures are essential to reduce the risk of explosion:

Explosion-Proof Equipment:

- Install electrical systems certified for use in hazardous areas (according to IEC 60079 or ATEX).

Dust Collection and Ventilation:

- Use appropriate dust extraction systems to minimize airborne dust and prevent accumulation. Ensure the ventilation system is designed to handle the dust’s chemical properties.

Static Control:

- Implement grounding and bonding to prevent static electricity build-up, especially in areas with low MIE dust.

Emergency Procedures:

- Develop a comprehensive emergency response plan for explosions and fires, including staff training and regular drills.

- Install explosion relief panels and automatic fire suppression systems in high-risk areas.

Step 7: Documentation and Continuous Monitoring

To maintain safety, it is important to document all tests, hazard assessments, and control measures. Safety systems must be regularly inspected and updated based on changing conditions.

- Risk Assessment Reports: Store detailed records of testing results, environmental evaluations, and safety procedures.

- Routine Inspections: Conduct regular inspections to detect any dust build-up or degradation in safety measures.

- Training Programs: Keep staff trained and updated on safety protocols and emergency procedures.

Conclusion

Determining whether a dust is combustible requires a structured process involving testing, environmental evaluation, and risk classification. Once combustible dust is identified, appropriate control measures and safety systems must be implemented to prevent explosions and ensure the safety of personnel and facilities.

Regular monitoring and documentation are essential to adapt to new risks and maintain a safe working environment. Following established national and international standards ensures compliance and mitigates potential hazards effectively.