1. Objective

The purpose of this guideline is to ensure the safe and efficient operation of Uninterruptible Power Supply (UPS) systems, reduce equipment downtime, extend service life, and prevent power interruptions from causing operational or data losses. This document provides a comprehensive framework for the installation, usage, and maintenance of UPS systems.

2. Scope

This policy applies to all UPS systems utilized within the organization, including those for critical servers, network equipment, and other essential devices that require uninterrupted power.

3. Roles and Responsibilities

Users and Operators:

- Ensure proper daily operation of the UPS system.

- Immediately report any abnormalities in the UPS operation.

- Follow the approved guidelines for operation and avoid misuse.

Facility or IT Management Team:

- Develop and oversee the implementation of UPS maintenance schedules.

- Ensure proper documentation of inspections, repairs, and upgrades.

- Coordinate with external service providers for advanced troubleshooting and annual maintenance.

Technical Support or Specialists:

- Perform installation, testing, and configuration of the UPS systems.

- Troubleshoot any system issues and provide timely resolutions.

- Train users and operators on best practices for UPS management.

4. Guidelines for UPS Operation

4.1 Start-Up and Shutdown Procedures

- Start-Up:

- Confirm proper input and output connections to the UPS system.

- Verify the load is within the system’s rated capacity.

- Power on the UPS in accordance with the manufacturer’s manual, ensuring each connected device is started sequentially.

- Shutdown:

- First, safely power down all connected devices.

- Turn off the UPS output followed by the input power source.

4.2 Safe Operation Practices

- Maintain load levels within the specified limits to prevent overloading.

- Avoid prolonged operation in bypass mode unless required for maintenance or repairs.

- Do not modify or tamper with input/output wiring without authorization.

4.3 Alarm and Fault Management

- Immediately notify the IT or facility management team if the UPS emits warning alarms.

- Do not continue using the UPS without addressing the warning or fault.

- Keep a log of any incidents for future analysis.

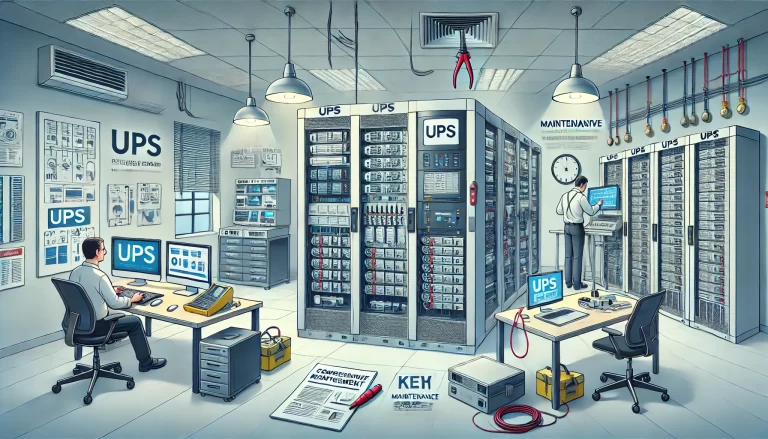

5. Maintenance Protocols

5.1 Routine Maintenance

- Daily Checks:

- Verify that the UPS is operating in normal mode with no alarms.

- Check the load percentage displayed on the system.

- Monthly Maintenance:

- Inspect for dust accumulation on the UPS exterior and clean using a dry cloth.

- Ensure the ventilation and air intakes are unobstructed.

5.2 Scheduled Inspections

- Quarterly Maintenance:

- Inspect all electrical connections for signs of wear or looseness.

- Check the battery status, including voltage levels and potential swelling or leakage.

- Semi-Annual Maintenance:

- Test the battery capacity using a load bank or manufacturer-recommended method.

- Measure output voltage, frequency, and power factor to confirm proper operation.

- Environmental Conditions:

- Maintain ambient temperature between 15°C and 25°C.

- Ensure the humidity level is between 30% and 70%.

- Check for signs of corrosion on terminals due to excessive moisture.

5.3 Annual Maintenance

- Engage certified professionals to conduct a detailed inspection.

- Include checks on critical components such as the rectifier, inverter, and bypass system.

- Replace aging or degraded batteries as needed.

- Perform a firmware or software upgrade, if recommended by the manufacturer.

6. Handling UPS Faults

6.1 Reporting and Diagnosis

- Operators must document the nature of the fault, including any warning codes displayed.

- Provide this information to the technical team for diagnosis.

6.2 Emergency Power Solutions

- Switch to backup power sources (e.g., generators) if the UPS is unable to supply adequate power.

- Implement a recovery plan to minimize disruptions to critical operations.

6.3 Post-Repair Testing

- After repair, conduct load testing to ensure the UPS is functioning properly before returning it to regular operation.

7. End-of-Life Management

Criteria for Replacement:

- UPS systems showing frequent failures or reduced performance over time.

- Batteries exceeding their rated lifecycle (typically 3–5 years) or with a significant drop in capacity.

- Systems older than 7–10 years, depending on usage and manufacturer guidelines.

Disposal Guidelines:

- Ensure UPS units are disposed of following environmental regulations.

- Partner with certified e-waste recyclers for proper handling of batteries and other components.

8. Training and Competency Development

Training Programs:

- Conduct regular training sessions for all UPS operators and users to improve familiarity with system operation, maintenance, and fault management.

- Provide hands-on workshops on emergency response actions in case of power interruptions.

Competency Assessments:

- Evaluate staff knowledge through periodic tests and practical exercises.

- Certify personnel to operate and maintain UPS systems based on their performance.

9. Documentation and Record-Keeping

Maintain logs for:

- Routine and scheduled maintenance activities.

- All incidents of faults and the corrective actions taken.

- Battery replacement and system upgrades.

Keep records of:

- Manufacturer manuals and service agreements.

- Inspection reports and testing certificates from third-party providers.

10. General Precautions

- Ensure the UPS room is free from combustible materials and excessive dust.

- Avoid exposing the UPS system to direct sunlight or excessive vibrations.

- Do not plug unauthorized devices into the UPS without prior approval.

11. Revision and Updates

This guideline will be reviewed annually or after significant changes in equipment or operational needs. Updates will be communicated to all relevant personnel.

By following these detailed guidelines, organizations can ensure that their UPS systems remain reliable and efficient, reducing risks associated with power interruptions and maximizing operational continuity.