In the process of industrial automation and material management, radar level meters are widely used due to their high accuracy and non-contact measurement.

However, in actual use, large measurement errors often occur, which not only affects the efficiency of the production process, but may also lead to waste of resources.

In order to help industry insiders better understand and solve this problem, this article will discuss in detail the main reasons for the large measurement errors of radar level meters and provide possible solutions.

Main causes of the problem:

1. Material surface conditions: The unevenness of the material surface, the stacking angle, or the gas and foam in the material may affect the reflection of the microwave signal, thereby affecting the accuracy of the measurement results.

2. Dielectric constant change: The dielectric constant of the material will change due to changes in temperature, humidity or other chemical components, which directly affects the propagation efficiency of the microwave signal and thus affects the measurement accuracy.

3. Environmental factors: In harsh environments such as high temperature, high pressure, dust, and steam, the sensitivity of the radar level meter may decrease, resulting in measurement data deviation.

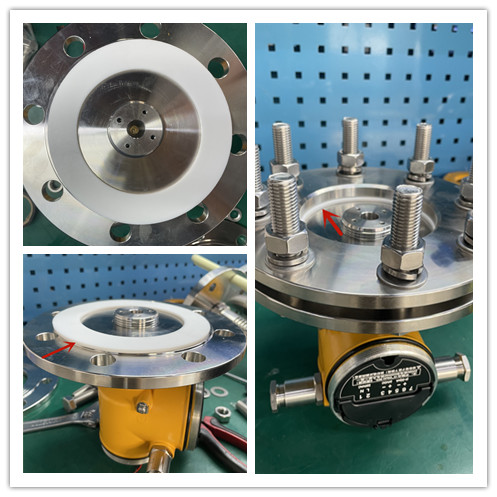

4. Installation position and angle: If the installation position and angle of the radar level meter are not properly selected, it may be interfered by surrounding structures, or it may not be correctly aligned with the material surface, causing misreading of the echo signal.

5. Instrument parameter settings: Incorrect parameter settings, such as improper range settings, inappropriate signal processing algorithm selection, etc., can also cause measurement errors.

Solutions:

1. Optimize surface adaptability: Select radar level meters suitable for different material characteristics, such as using high-frequency radar to reduce the impact of uneven material surfaces.

2. Calibrate and adapt dielectric constant: Calibrate the radar level meter regularly, and adjust the equipment parameters according to the actual working conditions so that it can adapt to the changes in the dielectric constant of the current material.

3. Improve environmental adaptability: Select radar level meters suitable for use in extreme environments, such as using special materials and protective measures to ensure that the equipment can work accurately in harsh environments.

4. Accurate installation and debugging: Ensure the rationality of the installation position of the radar level meter, reduce interference from surrounding structures through professional debugging, and ensure the correct reflection of microwave signals.

5. Parameter and algorithm optimization: Adjust the parameter settings of the radar level meter according to the specific application environment, and select the most appropriate signal processing algorithm to improve the accuracy and reliability of the data.

In summary, although radar level meters may face a variety of factors that lead to measurement errors in practical applications, their measurement accuracy can be significantly improved through systematic problem analysis and targeted solutions.

Technical personnel in the industry should regularly inspect and maintain the equipment, and constantly adjust and optimize the measuring equipment according to the working environment and material characteristics to ensure that the radar level meter can maintain high-precision measurement results under various complex conditions.